Variable compression ratio piston with limiting ring structure

A limit ring and compression ratio technology, applied to pistons, engine components, machines/engines, etc., can solve the problems of complex structure, poor reliability, and high manufacturing cost, and achieve reliable work, strong power output, and normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

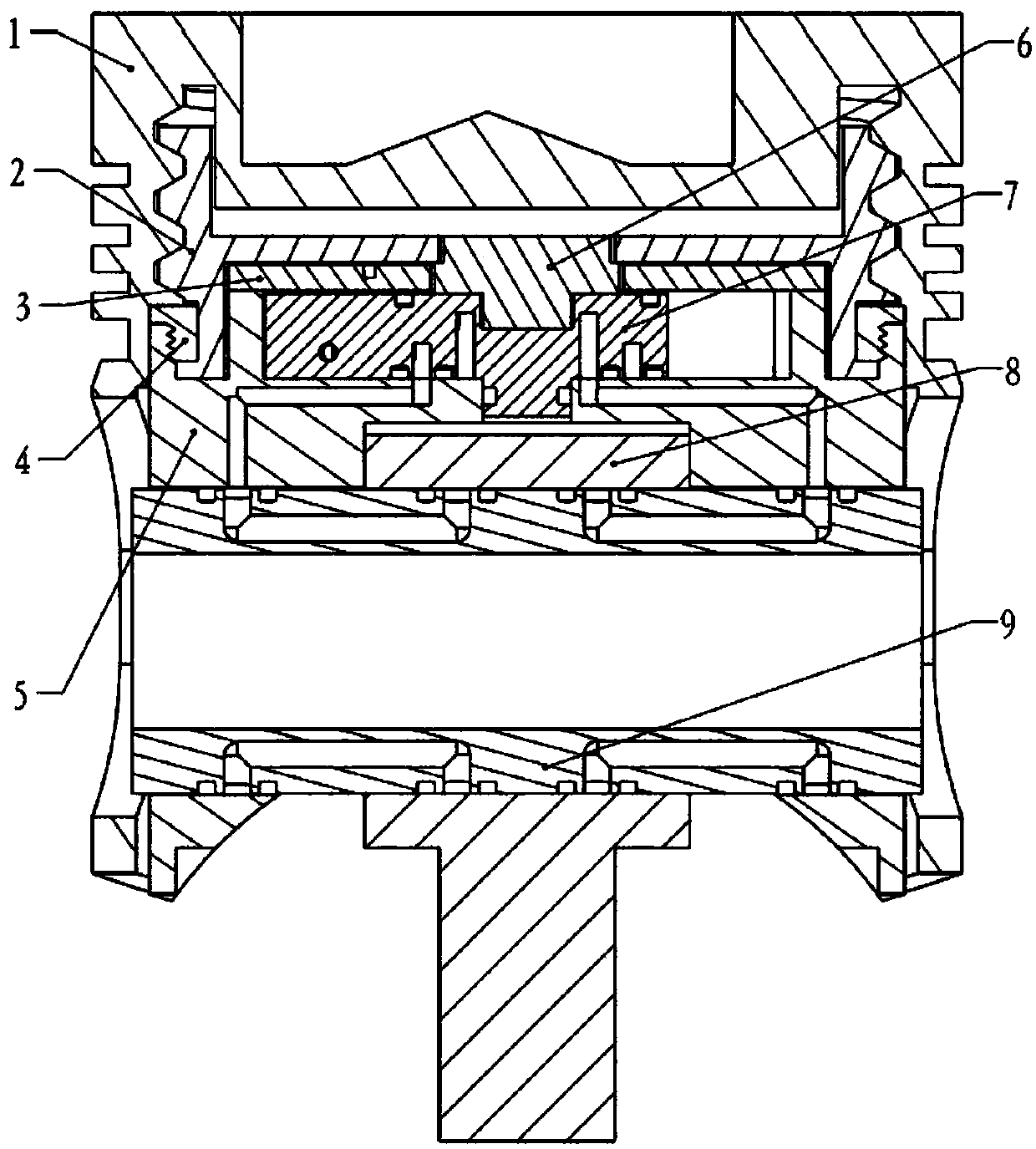

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

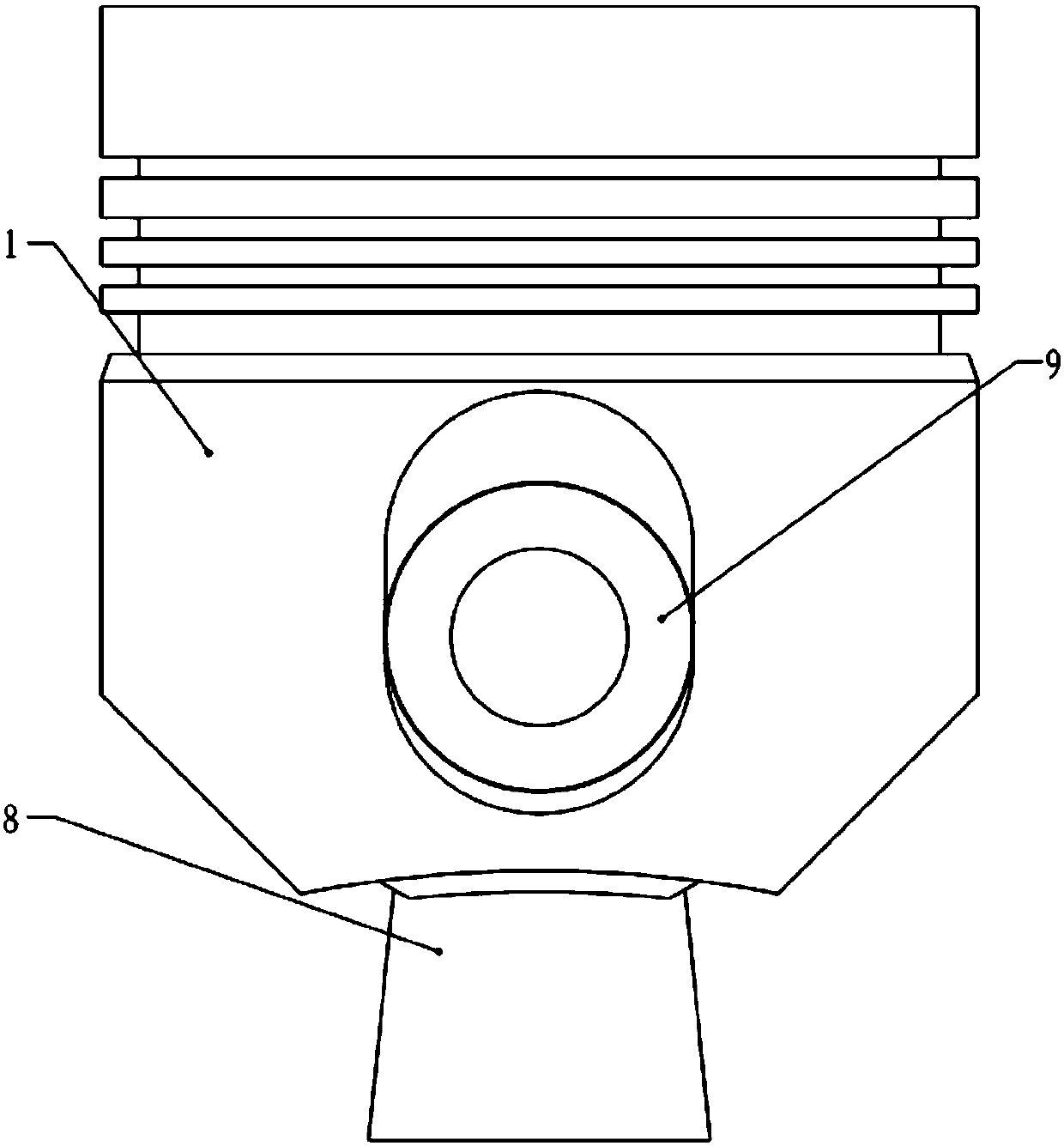

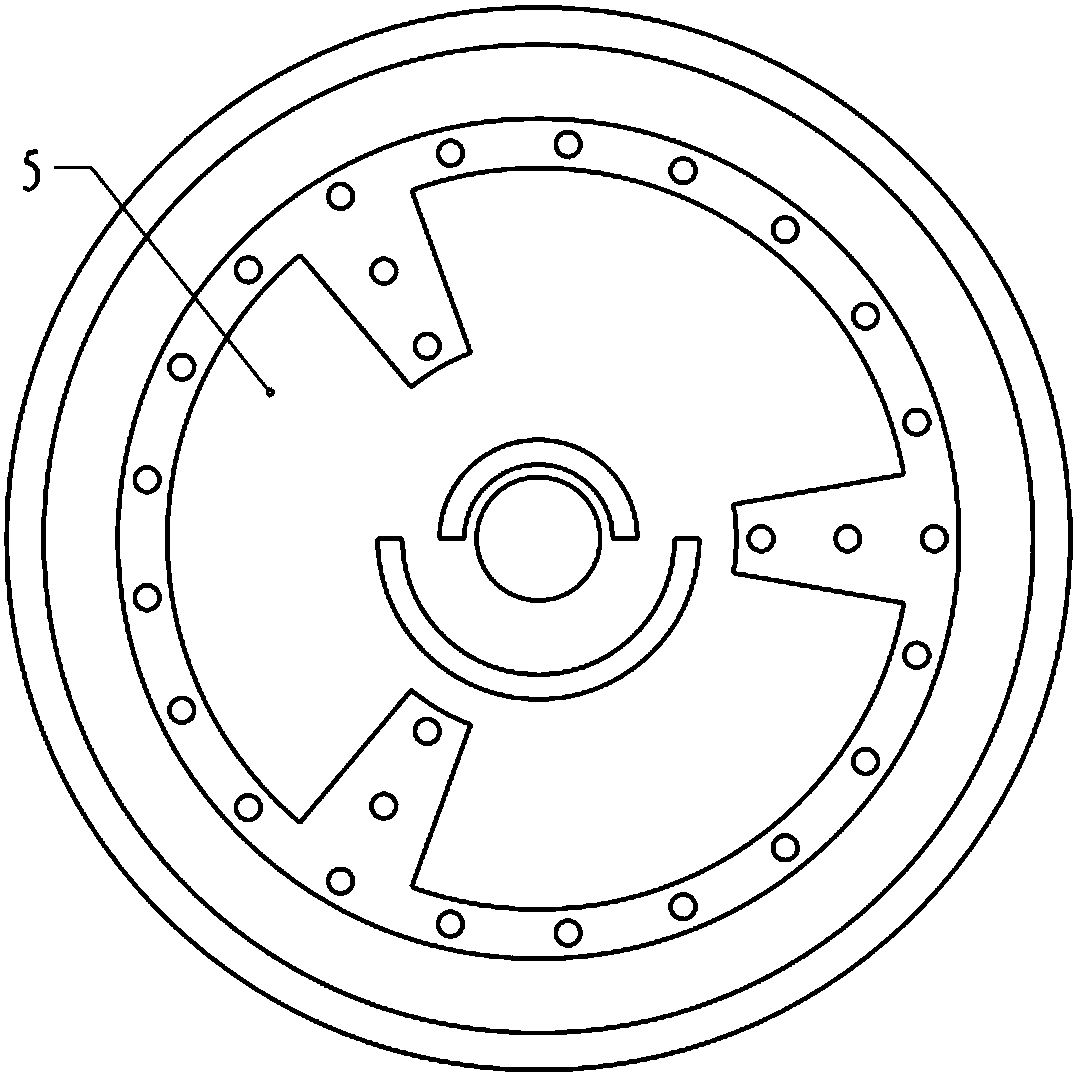

[0037] like figure 1 As shown, the vane motor 7 is placed on the center seat of the piston skirt 5, the oil groove on the vane motor 7 is directly opposite to the oil groove of the center seat of the piston skirt, and the sealing cover plate 3 is connected to the center of the piston skirt 5 by bolts. The seat is fixed; the end face of the vane motor 7 is matched with the side surface and the inner wall of the center seat, and the lower end face of the sealing cover plate 3, and the vane motor 7 can rotate 75 degrees in the center seat; the spline 6 connects the vane motor 7 and the helical runner 2 connection, the two limit rings 4 overlap along the cut surface, put the positioning pin 10 into the positioning pin hole of the limit ring cutout, prevent the two limit rings 4 from moving each other, and then clamp the limit ring 4 on the On the base of the spiral runner 2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com