Building template

A building formwork, flat plate technology, applied in the direction of construction, building structure, formwork/formwork components, etc., can solve problems such as easy to stick to dust, not resistant to alkali corrosion, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

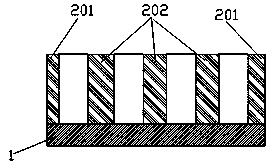

[0019] Such as figure 1 with figure 2 As shown, a building template according to an embodiment of the present invention includes a surface layer 1 and a reinforcement layer 2 . The reinforcement layer 2 is fixedly connected to the bottom surface of the surface layer 1 . The surface layer 1 is made of fiber-reinforced plastic; the reinforcement layer 2 includes a square-shaped reinforcement edge 201, and criss-cross reinforcement ribs 202 located inside the reinforcement edge 201, the reinforcement ribs 202 and the reinforcement edge 201 are fixedly connected, Both the reinforcing edge 201 and the reinforcing rib 202 are made of fiber reinforced plastic.

[0020] The construction formwork of the above embodiment is used to replace the existing aluminum alloy formwork. The building formwork of this embodiment includes a surface la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com