Polylactic acid fiber food grade binding rope

A polylactic acid fiber and binding rope technology, which is used in textiles and papermaking, flexible slender components, biological packaging, etc. Improve food safety, enhance appearance and quality, and improve surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

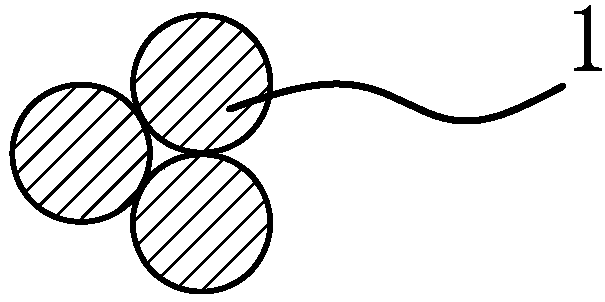

[0024] Such as figure 1 As shown, in the polylactic acid fiber food-grade binding rope, the binding rope is made of three pure polylactic acid fiber filaments 1, and the specifications of the polylactic acid fiber filaments are 150D-300D. The binding rope formed by plying polylactic acid fiber filaments has the advantages of smooth surface and not easy to stick unhygienic impurities. Coupled with the natural antibacterial and antibacterial properties of polylactic acid fiber, it has a good promotion effect on improving food hygiene and safety.

[0025] The raw material of polylactic acid fiber (PLA) is lactic acid obtained from cornstarch, so this fiber is also called corn fiber, which can be made from sugar beets or grains through glucose fermentation to reduce the cost of preparing lactic acid polymers. Polylactic acid with high molecular weight can be obtained by chemical polymerization of cyclic dimer of lactic acid or direct polymerization of lactic acid. Products made ...

Embodiment 2

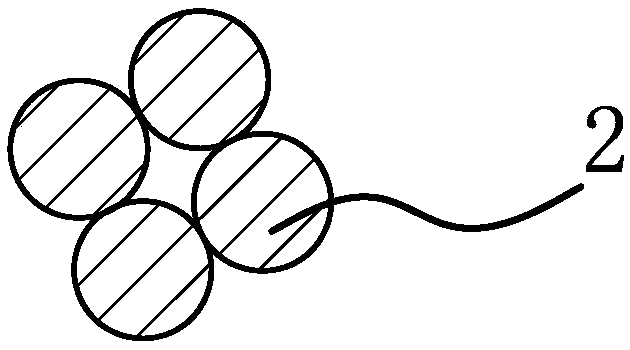

[0029] Such as figure 2 As shown in the present polylactic acid fiber food-grade binding rope, the binding rope is made of 4 polylactic acid fiber staple fiber yarns 2 ply, and the specifications of the polylactic acid fiber yarns are 8s-40s. The binding rope formed by plying polylactic acid fiber yarns has simple process and low cost. The pre-shrinking process is required to complete the joint stock, and the binding rope is pre-shrunk when it encounters water to prevent the shrinkage rate of the finished product from increasing due to water contact during use. After the pre-shrinking treatment is completed, the shrinkage rate of the binding rope after high-temperature cooking can be controlled. Between 5% and 30%, the bundled products are not easy to scatter after high-temperature cooking, but will be relatively tightened to increase the bundle strength.

[0030] From the perspective of food safety, polylactic acid fiber is naturally environmentally friendly because it uses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com