Preparation method of aluminum-based composite material reinforced by particles through uniform dispersion

An aluminum-based composite material and uniform dispersion technology, which is applied in the field of aluminum-based composite materials, can solve problems such as difficult control of particle size and distribution, achieve the effects of avoiding local defects, solving uneven dispersion and particle aggregation, and enhancing matrix strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

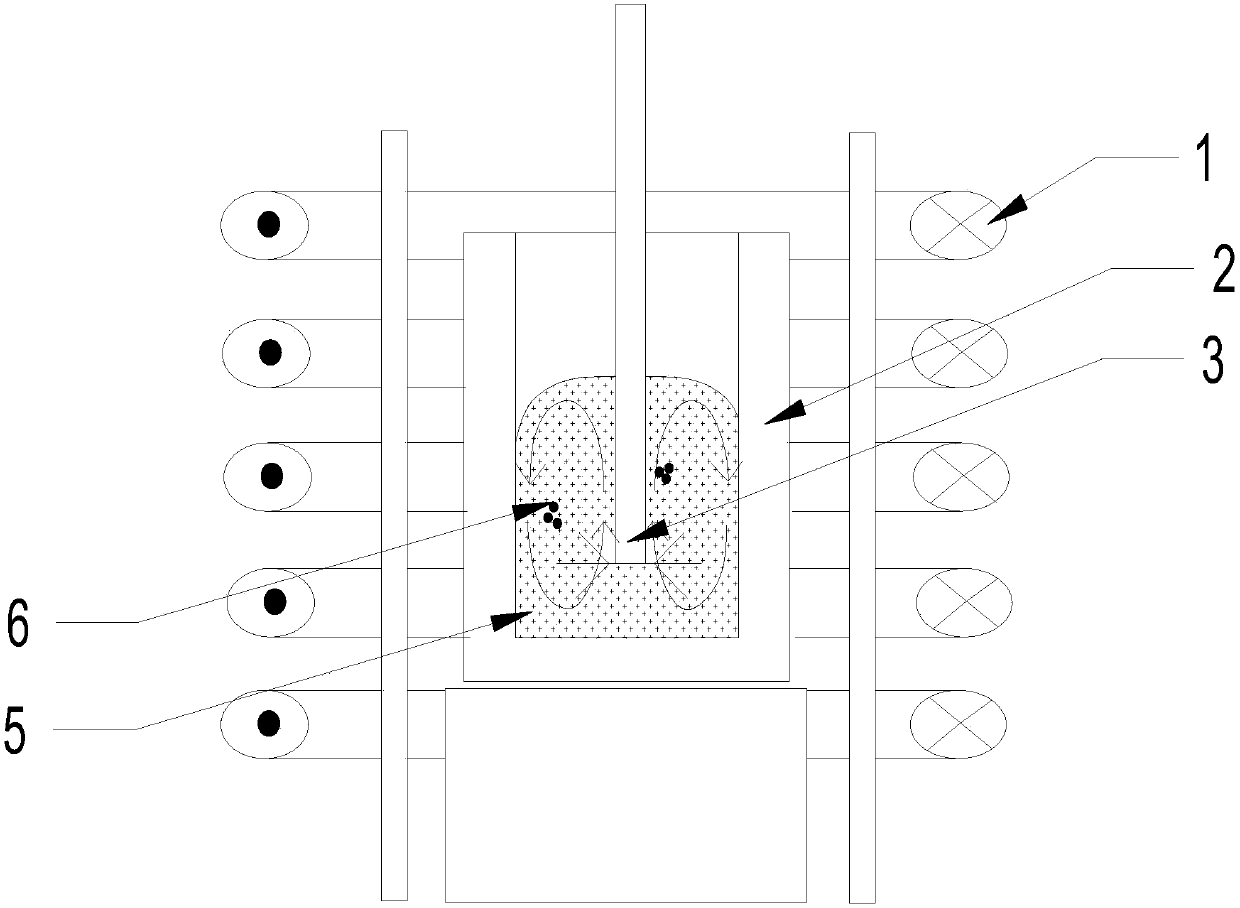

[0020] A method for preparing an aluminum matrix composite material reinforced by uniform dispersion of particles, the specific steps are as follows:

[0021] 1) adding the metal Al-Si alloy into the graphite crucible 2, and performing electromagnetic induction heating through the electromagnetic field generating device 1 so that the alloy is in a molten state;

[0022] 2) Keep the molten alloy 5 at 780° C. by controlling the intensity of the electromagnetic field, and keep the temperature for 5 minutes;

[0023] 3) Preheat SiC particles with 4.5% volume of the molten alloy 5 to 300° C., and slowly add them into the molten alloy 5, and mix the SiC particles with the molten alloy 5 under the stirring of the mechanical stirrer 3 and the electromagnetic field generator 1;

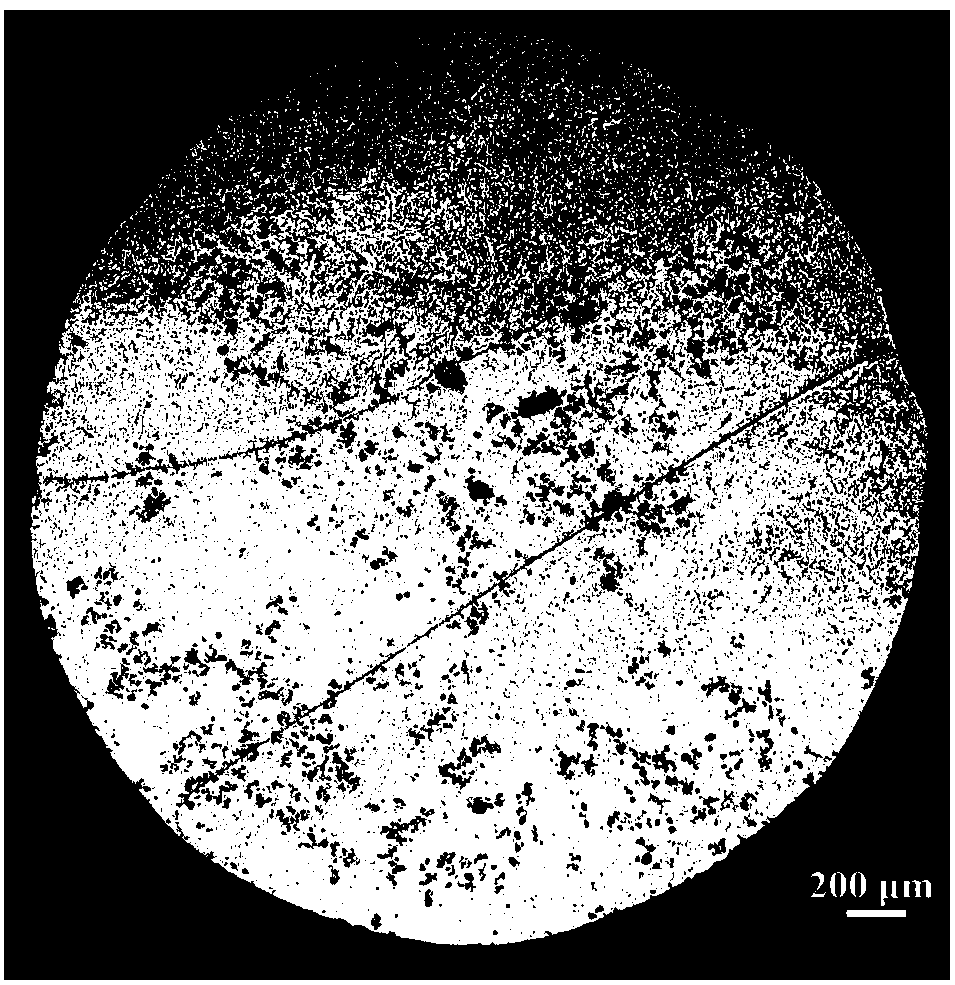

[0024] 4) By controlling the strength of the electromagnetic field, the temperature of the alloy is kept in the eutectic region of the Al-Si alloy, and it is fully stirred for 5 minutes, so that the precipitat...

Embodiment 2

[0026] A method for preparing an aluminum matrix composite material reinforced by uniform dispersion of particles, the specific steps are as follows:

[0027] 1) adding the metal Al-Si alloy into the graphite crucible 2, and performing electromagnetic induction heating through the electromagnetic field generating device 1 so that the alloy is in a molten state;

[0028] 2) Keep the molten alloy 5 at 800° C. by controlling the intensity of the electromagnetic field, and keep the temperature for 5 minutes;

[0029] 3) Preheat the SiC particles with 5% volume of the molten alloy 5 to 300°C, and slowly add them into the molten alloy 5, and mix the SiC particles with the molten alloy 5 under the stirring of the mechanical stirrer 3 and the electromagnetic field generator 1;

[0030] 4) By controlling the strength of the electromagnetic field, the temperature of the alloy is kept in the eutectic region of the Al-Si alloy, and it is fully stirred for 8 minutes, so that the precipitat...

Embodiment 3

[0032] A method for preparing an aluminum matrix composite material reinforced by uniform dispersion of particles, the specific steps are as follows:

[0033] 1) adding the metal Al-Si alloy into the graphite crucible 2, and performing electromagnetic induction heating through the electromagnetic field generating device 1 so that the alloy is in a molten state;

[0034] 2) Keep the molten alloy 5 at 820° C. by controlling the intensity of the electromagnetic field, and keep the temperature for 5 minutes;

[0035] 3) Preheat the SiC particles with 5.5% volume of the molten alloy 5 to 300°C, and slowly add them into the molten alloy 5, and mix the SiC particles with the molten alloy 5 under the stirring of the mechanical stirrer 3 and the electromagnetic field generator 1;

[0036] 4) By controlling the strength of the electromagnetic field, the temperature of the alloy is kept in the eutectic region of the Al-Si alloy, fully stirred for 10 minutes, so that the precipitated Si c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com