Double-vertical-furnace system and method for producing iron containing product through system

A shaft furnace and product technology, applied in the field of metallurgy, can solve the problems of reducing the comprehensive utilization rate of reducing gas, increasing the requirements for preparing reducing gas, energy utilization rate, etc., so as to improve energy utilization rate, reduce equipment complexity, and reduce emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

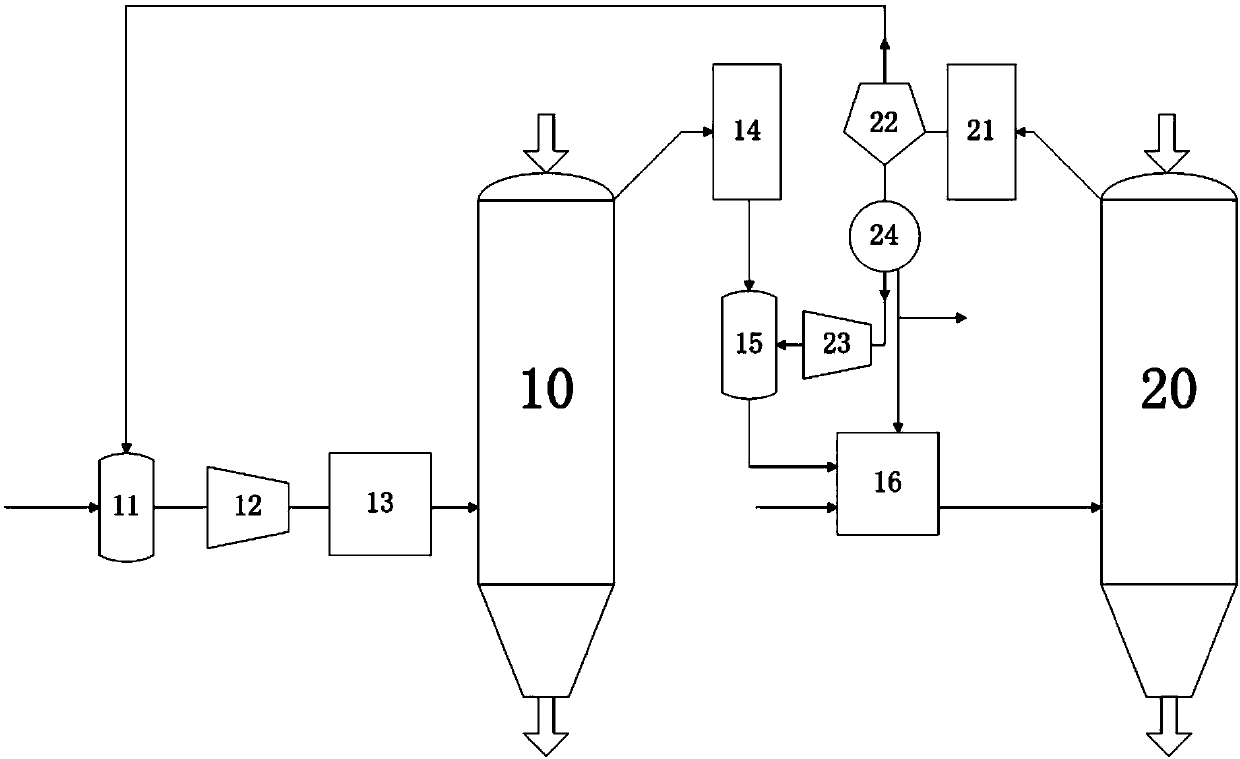

[0050] refer to figure 1 , the joint production system and method are specifically:

[0051] Put vanadium-titanium-magnetite pellets in the first shaft furnace 10, put iron concentrate pellets in the second shaft furnace 20, and mix the fresh reducing gas and the hydrogen-rich gas provided by the hydrogen extraction device in the mixing tank 11 to make the gas composition Meet the requirements of the reaction, so that H 2 / CO ratio is 5, the effective reducing gas (H 2 +CO) volume ratio ≥ 0.90, the mixed gas is passed into the first compressor 12, so that the pressure of the mixed gas reaches 0.7MPa, and then it is passed into the heating furnace 13, and the temperature of the mixed gas is heated to 1050 by the heating furnace 13 °C is passed into the first shaft furnace as the first reducing gas. React in the first shaft furnace 10 to produce vanadium-titanium sponge iron and obtain the first top gas. After the first furnace top gas passes through the first water washing ...

Embodiment 2

[0056] refer to figure 1 , the joint production system and method are specifically:

[0057] Put vanadium-titanium-magnetite pellets in the first shaft furnace 10, put iron concentrate pellets in the second shaft furnace 20, and mix the fresh reducing gas and the hydrogen-rich gas provided by the hydrogen extraction device in the mixing tank 11 to make the gas composition Meet the requirements of the reaction, so that H 2 / CO ratio is 4, effective reducing gas (H 2 +CO) volume ratio ≥ 0.95, the mixed gas is passed into the first compressor 12, so that the pressure of the mixed gas reaches 0.8MPa, then it is passed into the heating furnace 13, and the temperature of the mixed gas is heated to 1000 by the heating furnace 13 °C is passed into the first shaft furnace as the first reducing gas. React in the first shaft furnace 10 to produce vanadium-titanium sponge iron and obtain the first top gas. After the first furnace top gas passes through the first water washing tower 14...

Embodiment 3

[0061] refer to figure 1 , the joint production system and method are specifically:

[0062] Put vanadium-titanium-magnetite pellets in the first shaft furnace 10, put iron concentrate pellets in the second shaft furnace 20, and mix the fresh reducing gas and the hydrogen-rich gas provided by the hydrogen extraction device in the mixing tank 11 to make the gas composition Meet the requirements of the reaction, so that H 2 / CO ratio is 3, effective reducing gas (H 2 +CO) volume ratio ≥ 0.90, the mixed gas is passed into the first compressor 12, so that the pressure of the mixed gas reaches 0.65MPa, then it is passed into the heating furnace 13, and the temperature of the mixed gas is heated to 950 by the heating furnace 13 °C is passed into the first shaft furnace as the first reducing gas. React in the first shaft furnace 10 to produce vanadium-titanium sponge iron and obtain the first top gas. After the first furnace top gas passes through the first water washing tower 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com