A kind of equipment and method for producing lactobacillus

A technology of lactobacillus and lactic acid bacteria, applied in the directions of biochemical equipment and methods, microorganism-based methods, microorganisms, etc., can solve the problems of small production volume of finished products, cumbersome large-scale production, etc., to ensure freshness, improve final profits, The effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

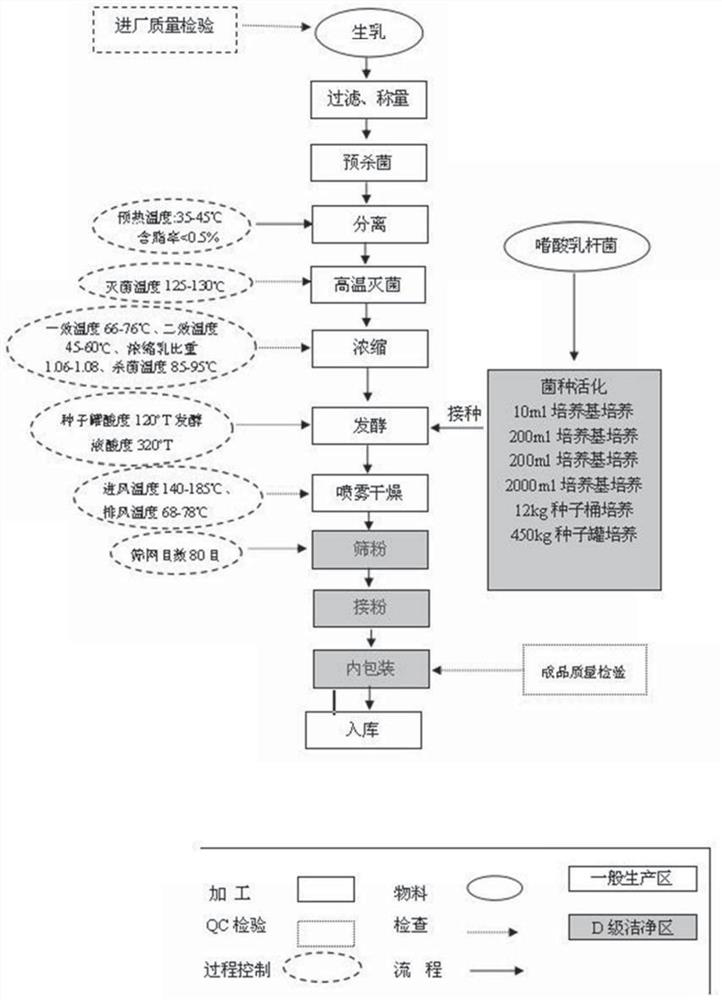

[0084] Receiving, filtering, weighing, pre-sterilizing, separating, sterilizing, concentrating, fermenting, and spray drying of raw milk are general production areas, and strain activation culture, strain expansion culture, powder inoculation, and packaging are grade-D clean areas, with a temperature of 18 -26°C, relative humidity 20-65%.

[0085] 1. Preparation of concentrated milk

[0086] 1 filter, weigh

[0087] After the raw milk is filtered through the pipeline filter, it is pumped into the hanging electronic scale for weighing, and then enters the milk tank.

[0088] 2 pre-sterilized

[0089] The raw milk is pre-sterilized by a plate heat exchanger at 60-65°C, then cooled to below 10°C, and put into a 25T milk storage tank for storage.

[0090] 3 separated

[0091] Raw milk passes through a plate heat exchanger, heated to a temperature between 35-45°C, and starts the separator. When the rotation speed reaches 1500 rpm, the separation begins. The separated skim milk ...

Embodiment 2

[0146] 1. After the raw milk is filtered and weighed, a total of 52386kg of raw milk is received. At the same time, it is pre-sterilized at a temperature of 62°C and cooled at a temperature of 6°C, and put into a 25T milk storage tank.

[0147] 2. Raw milk is preheated by a plate heat exchanger at a temperature of 39°C-41°C, separated in an automatic separator at 1500 rpm, and the fat content is tested every hour to control it between 0.1%-0.2%.

[0148] 3. The skim milk is sterilized by a fully automatic straight tube sterilizing unit at a temperature of 130°C. 4. The skim milk is passed through an automatic double-effect falling-film evaporator, the first-effect temperature is 75°C-76°C, the second-effect evaporation temperature is 60°C, and the sterilization temperature is between 88°C-90°C to obtain concentrated milk. Detect the specific gravity of concentrated milk every hour, and control it at 1.06-1.07Be (Baume degree).

[0149] 5. The third-generation strains, fourth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com