A kind of preparation method with high corrosion resistance epoxy resin coating

A technology capable of epoxy resin and composite epoxy resin, applied in improving and improving the anti-corrosion performance of epoxy resin coating, the preparation field of epoxy resin coating, can solve problems such as poor, achieve enhanced compatibility, The effect of improving anti-corrosion ability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1 silane coupling agent 2-(3,4-epoxycyclohexyl) ethyltriethoxysilane

[0033] Weigh 5g of 1,2-epoxy-4-vinylcyclohexane, dissolve it in an appropriate amount of toluene, and add it into a 250ml three-neck flask. in N 2Under the atmosphere, add 10ppm Karstedt catalyst and raise the reaction temperature to 65°C, then add 7.24g triethoxysilane dropwise to the reaction solution, after the dropwise addition, keep stirring at 800 rpm for 6h, and the reaction product is dissolved in In toluene; after rotary distillation of toluene, the target product of 2-(3,4-epoxycyclohexyl)ethyltriethoxysilane was obtained as a colorless transparent liquid.

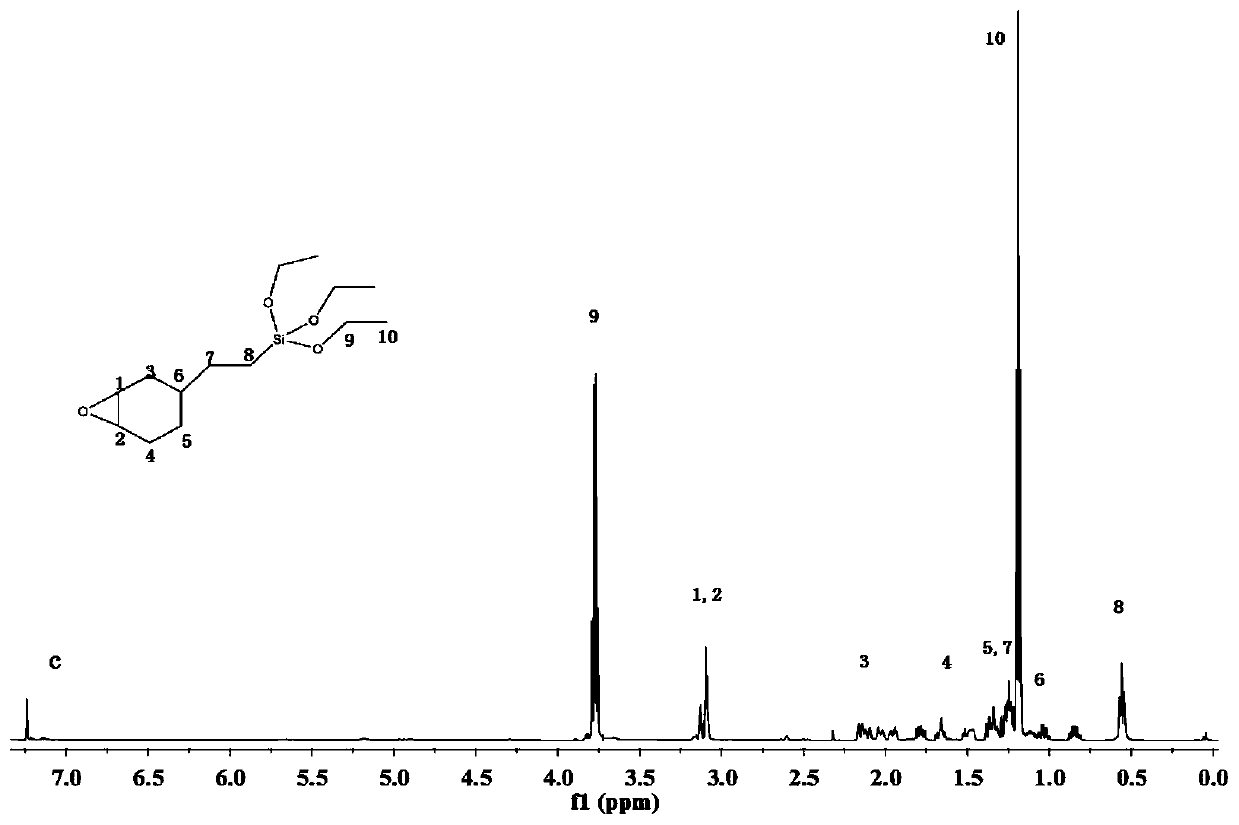

[0034] figure 1 Provide the proton nuclear magnetic resonance spectrogram ( 1 H-NMR) and chemical formula. The δ0.5 appearing in the product is -CH 2 The multiplet of -Si-, 2-(3,4-epoxycyclohexyl)ethyltriethoxysilane was successfully synthesized.

Embodiment 2

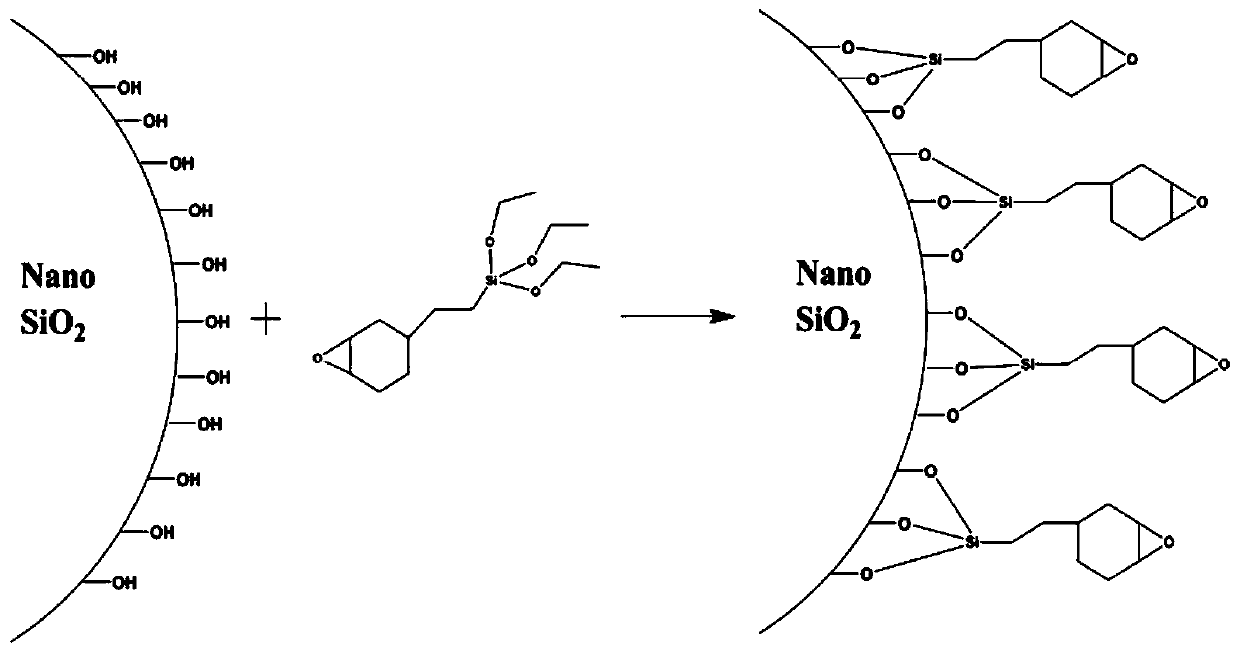

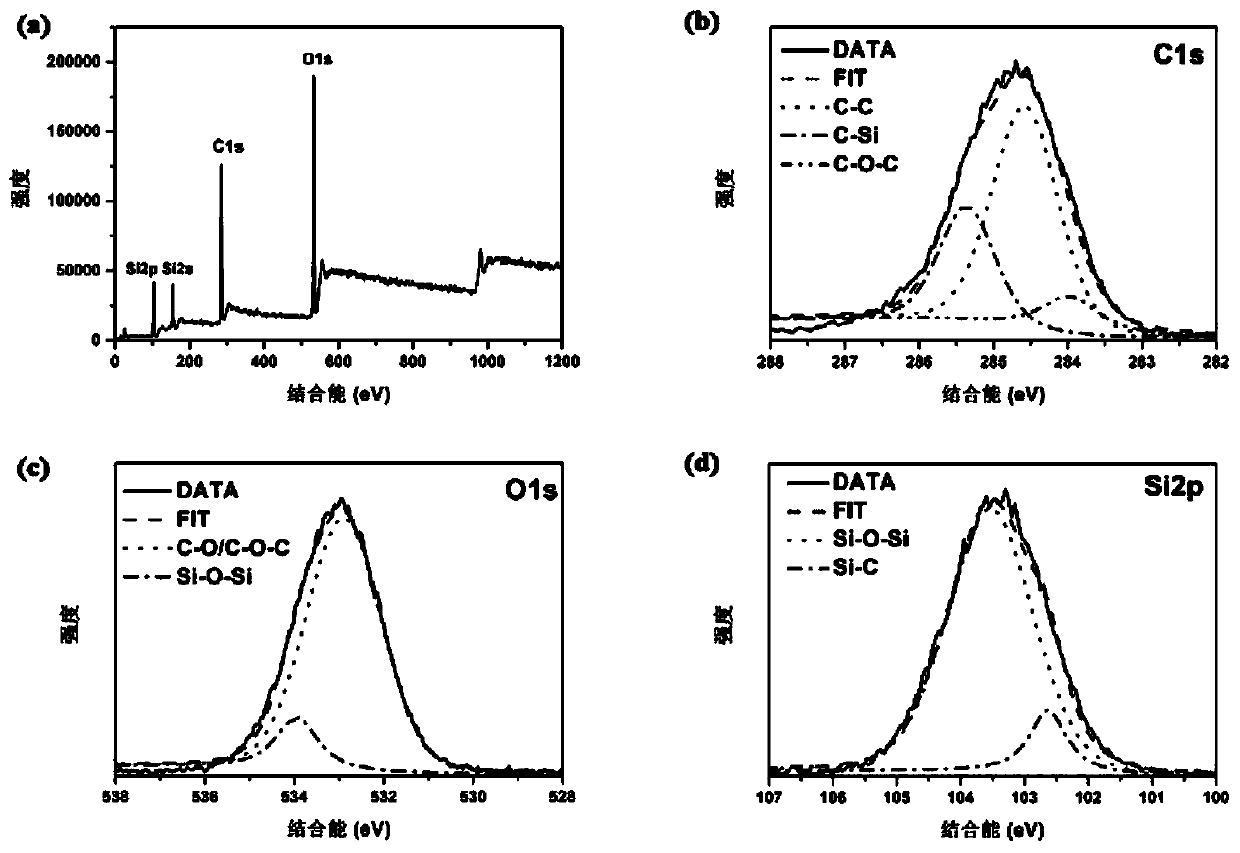

[0035] The surface modification of embodiment 2 nano silicon dioxide

[0036] Stir 10 g of silica nanoparticles in 200 ml of ethanol at a high speed at room temperature. After the silica is uniformly dispersed, the pH value of the nano silica-ethanol suspension is adjusted to 2-3 with glacial acetic acid. in N 2 Under the atmosphere, 5.4g of silane coupling agent and appropriate amount of deionized water were slowly added dropwise to the nano-silica-ethanol suspension. After the dropwise addition, the temperature was raised to 60° C. and kept under reflux for 12 hours. After the reaction, the ETEO-modified nano-silica-ethanol suspension was centrifuged several times, washed with ethanol and then dried in a vacuum oven for 48 hours to obtain the modified nano-silica particles (that is, the aforementioned "ETEO-modified nano-silica powder", labeled ETEO-SiO 2 ).

[0037] The silane coupling agent used in this example is 2-(3,4-epoxycyclohexyl)ethyltriethoxysilane prepared in...

Embodiment 3

[0041] The preparation of embodiment 3 epoxy resin composite coatings

[0042] Add 100g of epoxy resin to an appropriate amount of n-butanol and xylene as a compound solvent, add 5g of ETEO-modified nano-silica powder, and 40-70g of polyamide curing agent and stir for 30 minutes at high speed. After the stirring is finished, the steel plate is spray-coated, and then the steel plate is put into an oven at 60° C. for curing for 4 hours, so that the coating thickness is 80-100 μm.

[0043] In the compound solvent of n-butanol and xylene, 1-3g leveling agent and 2-5g defoamer can also be added together with the curing agent.

[0044] The carbon steel substrate used in the experiment is Q235 steel plate, and the size of the steel plate after processing is: 12cm×5cm×2mm. Before use, the surface of the steel plate was cleaned with ethanol and dried in a vacuum oven.

[0045] Since the coating substrate of this experiment is epoxy resin, a compound solvent of xylene and n-butanol is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com