Catalyst for preparation of aliphatic polycarbonate by reaction of carbon dioxide and cyclohexene oxide and catalysis method

A technology for oxidizing cyclohexene and carbon dioxide, which is applied in the field of organic synthesis, can solve problems such as single industrial structure, and achieve the effects of high catalytic efficiency, mild catalytic reaction conditions, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of catalyst 2,6-bis(2-formylphenoxymethyl)pyridine 2-amino-6-picoline zinc complex is as follows:

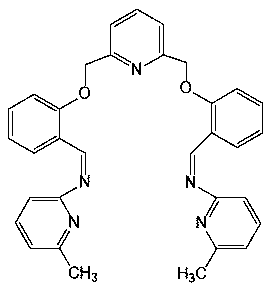

[0024] (1) Dissolve 1.08g (0.01mol) of 2-amino-6-methylpyridine and 1.74g (0.005mol) of 2,6-bis(2-formylphenoxymethyl)pyridine in 15mL of methanol, at room temperature Add the methanol solution of 2-amino-6-methylpyridine dropwise to the methanol solution of 2,6-bis(2-formylphenoxymethyl)pyridine, heat to reflux after the dropwise addition, and continue to stir for 2h. The precipitate was filtered off, washed with ether, and dried to obtain 2,6-bis(2-formylphenoxymethyl)pyridinyl 2-amino-6-picoline ligand; 2,6-bis( The structural formula of 2-formylphenoxymethyl)pyridine 2-amino-6-picoline ligand is

[0025]

[0026] Structural characterization of ligands: 1 H NMR (400 MHz, CDCl 3 ): δ 2.67(s, 6H, -CH 3 ), 5.82(s,4H, -CH 2 ), 6.8~8.6(m, 17H, aromatic H), 8.83(s, 2H, -CH);

[0027] (2) Weigh 0.1mol of 2,6-bis(2-formylphenoxymethyl)pyridine 2...

Embodiment 2

[0029] The preparation method of catalyst 2,6-bis(2-formylphenoxymethyl)pyridine 2-amino-6-picoline zinc complex is as follows:

[0030] (1) Dissolve 1.08g (0.01mol) of 2-amino-6-methylpyridine and 1.91g (0.0055mol) of 2,6-bis(2-formylphenoxymethyl)pyridine in 15mL of methanol, at room temperature Add the methanol solution of 2-amino-6-methylpyridine dropwise to the methanol solution of 2,6-bis(2-formylphenoxymethyl)pyridine, heat to reflux after the dropwise addition, and continue to stir for 1h. The precipitate was filtered out, washed with ether, and dried to obtain 2,6-bis(2-formylphenoxymethyl)pyridine 2-amino-6-picoline ligand;

[0031](2) Weigh 0.1mol of 2,6-bis(2-formylphenoxymethyl)pyridine 2-amino-6-picoline ligand into a container, vacuumize, fill with nitrogen, and under the protection of nitrogen, Add 200mL toluene to dissolve the bis-2,6-bis(2-formylphenoxymethyl)pyridine 2-amino-6-picoline ligand, and add toluene containing 0.13mol diethylzinc under ice-salt ba...

Embodiment 3

[0033] The method for preparing aliphatic polycarbonate by using catalyst 2,6-bis(2-formylphenoxymethyl)pyridinium 2-amino-6-picoline zinc to catalyze the reaction of carbon dioxide and cyclohexene oxide, the steps are as follows:

[0034] (1) Put 0.10g of the 2,6-bis(2-formylphenoxymethyl)pyridinium 2-amino-6-picoline zinc catalyst prepared in Example 1 into a vacuum-dried autoclave (high pressure A stirring bar is placed in the reaction kettle), vacuum-dried at 100°C for 1 hour, cooled to room temperature, filled with carbon dioxide to normal pressure; 10.42mL (10g) cyclohexene oxide was added to the reaction kettle, and the temperature was raised to 150 ℃, fill with carbon dioxide, keep the pressure at 4MPa, stir with magnetic force, after reacting for 30h, cool to room temperature, stop the reaction;

[0035] (2) Take out the reaction solution, distill off the unreacted cyclohexene oxide, dissolve the residue with dichloromethane, filter, wash the filtrate with dilute acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com