Method for synthesizing m-cresol by 3-methylcyclohexenone dehydrogenation

A technology for the dehydrogenation of methylcyclohexenone, applied in chemical instruments and methods, preparation of organic compounds, organic compound/hydride/coordination complex catalysts, etc. Difficult to recycle and other problems, to achieve the effect of easy separation and recycling, high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

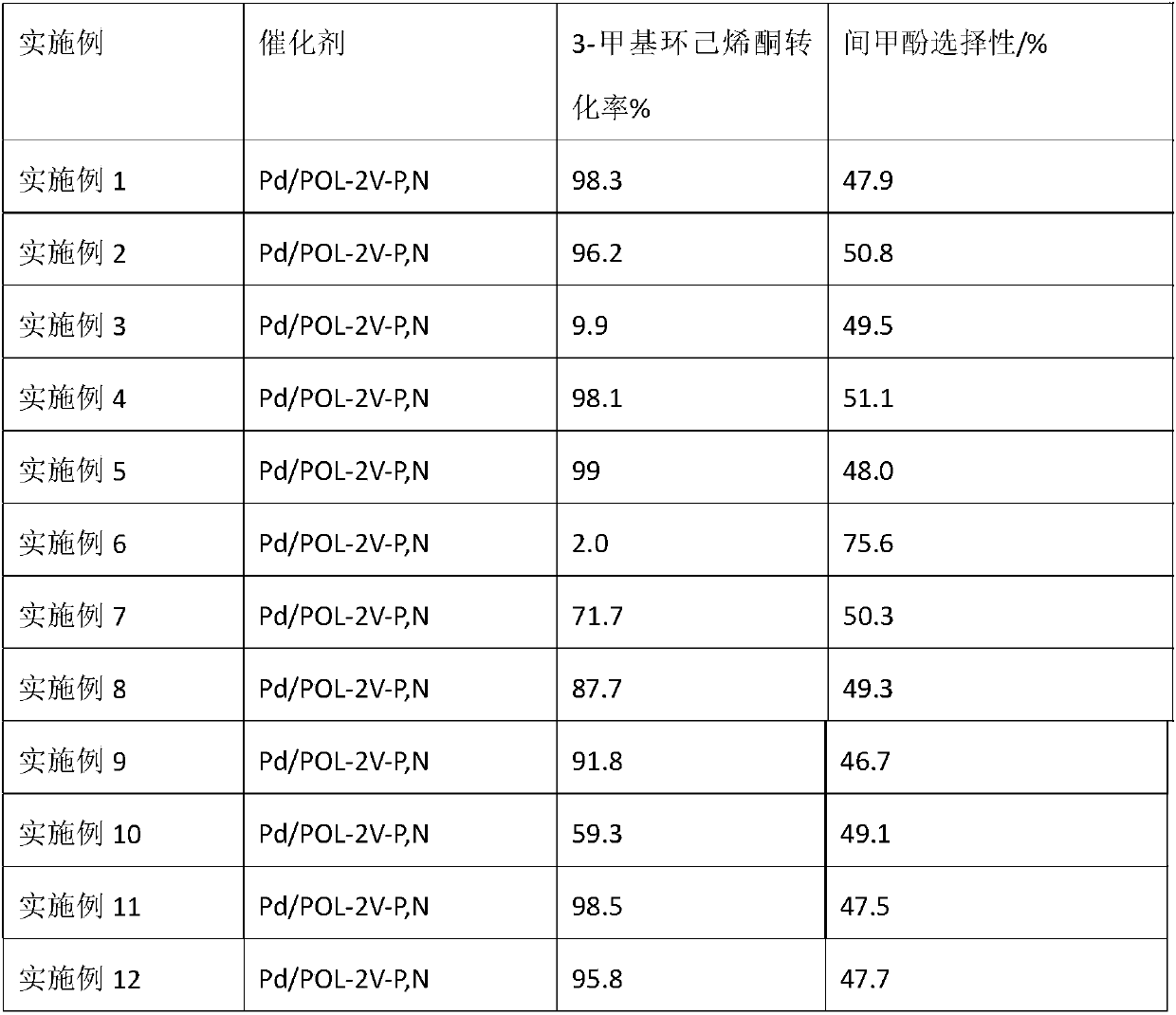

Embodiment 1

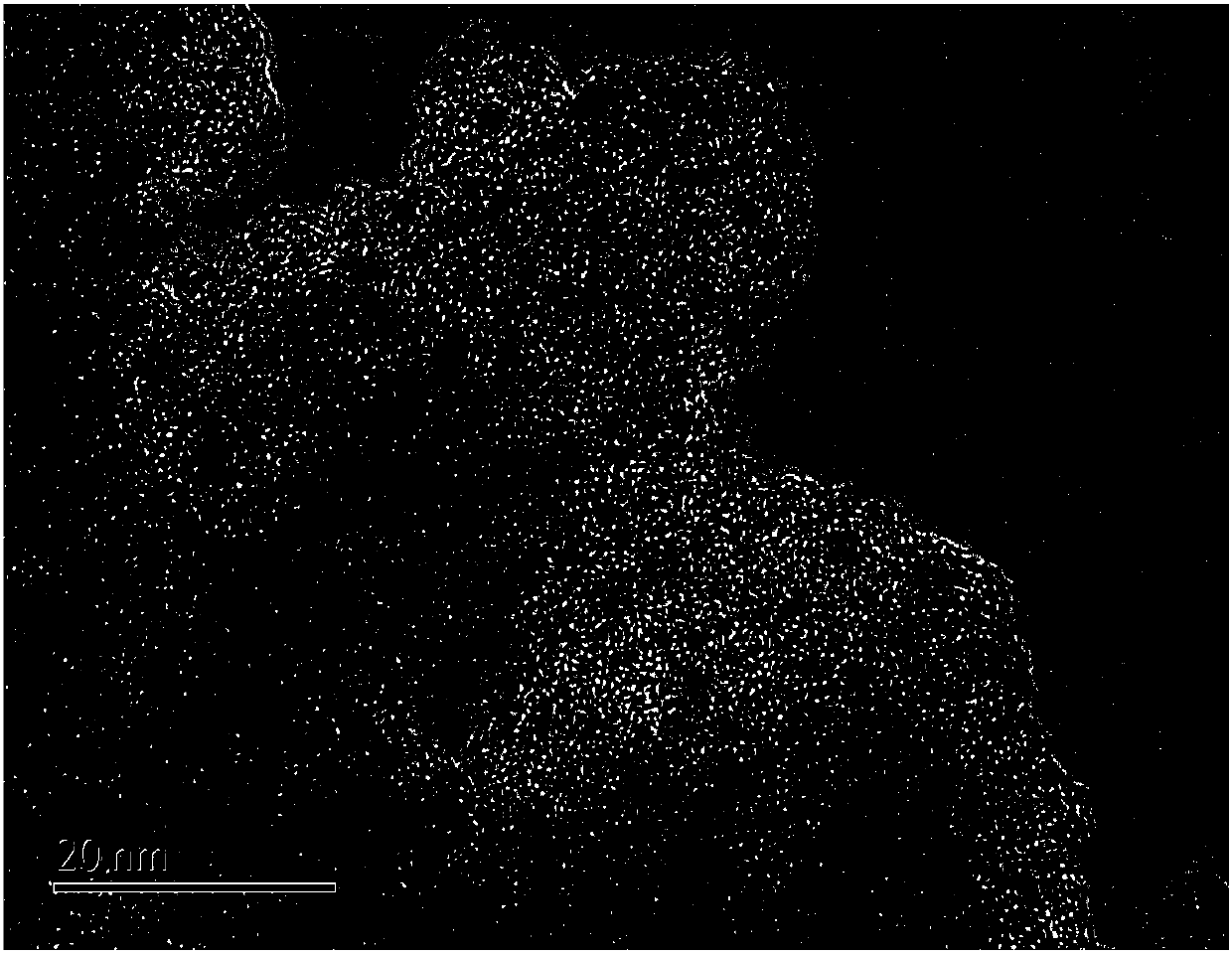

[0018] Under argon atmosphere, add 0.7087g of POL-2V-P,N porous polymer material and 14ml of acetonitrile into a 50ml single-necked flask. After stirring for 30min, add 0.0394g of palladium acetate. Stir at room temperature for 24h, at 338K. Dry under vacuum. The dried sample is placed in a quartz tube with an inner diameter of 10 cm, and hydrogen is introduced. The flow rate of the hydrogen is 100 ml / min. Then the quartz tube is heated to 423K at a rate of 5K / min. Pd / POL-2V-P,N catalyst supported by porous phosphine-containing and nitrogen-containing polymer can be obtained after reduction for 5 hours. The morphology of the prepared Pd / POL-2V-P, N palladium-based catalyst was characterized by SEM and TEM electron microscope, see figure 1 with figure 2 .

[0019] In a 50ml solvent storage bottle, 0.89g of 3-methylcyclohexenone, 0.032g of Pd / POL-2V-P, N palladium-based catalyst, and 0.1072g of potassium carbonate were placed in sequence. The glass reactor was sealed, and the ...

Embodiment 2

[0021] The mass of potassium carbonate is 0.2144g. Other conditions are the same as in Example 1.

Embodiment 3

[0023] The reaction temperature was 393K, and other conditions were the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com