Manufactured sand self-compacting concrete applied to corrugated steel web box girder

A technology of self-compacting concrete and corrugated steel webs, which is applied in the field of building materials, can solve problems such as difficult vibration, unstable quality, dense reinforcement, etc., and achieve good working performance, good filling performance, energy saving and environmental protection at a low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 438kg of PO42.5 cement, 79kg of fly ash, 647kg of machine-made sand, 1102kg of crushed stone with a particle size of 5 to 20mm, 4.9kg of polycarboxylate superplasticizer and 165kg of water into a mixer and mix evenly to obtain about 40L. Apply to corrugated steel Machine-made sand self-compacting concrete samples of web box girders.

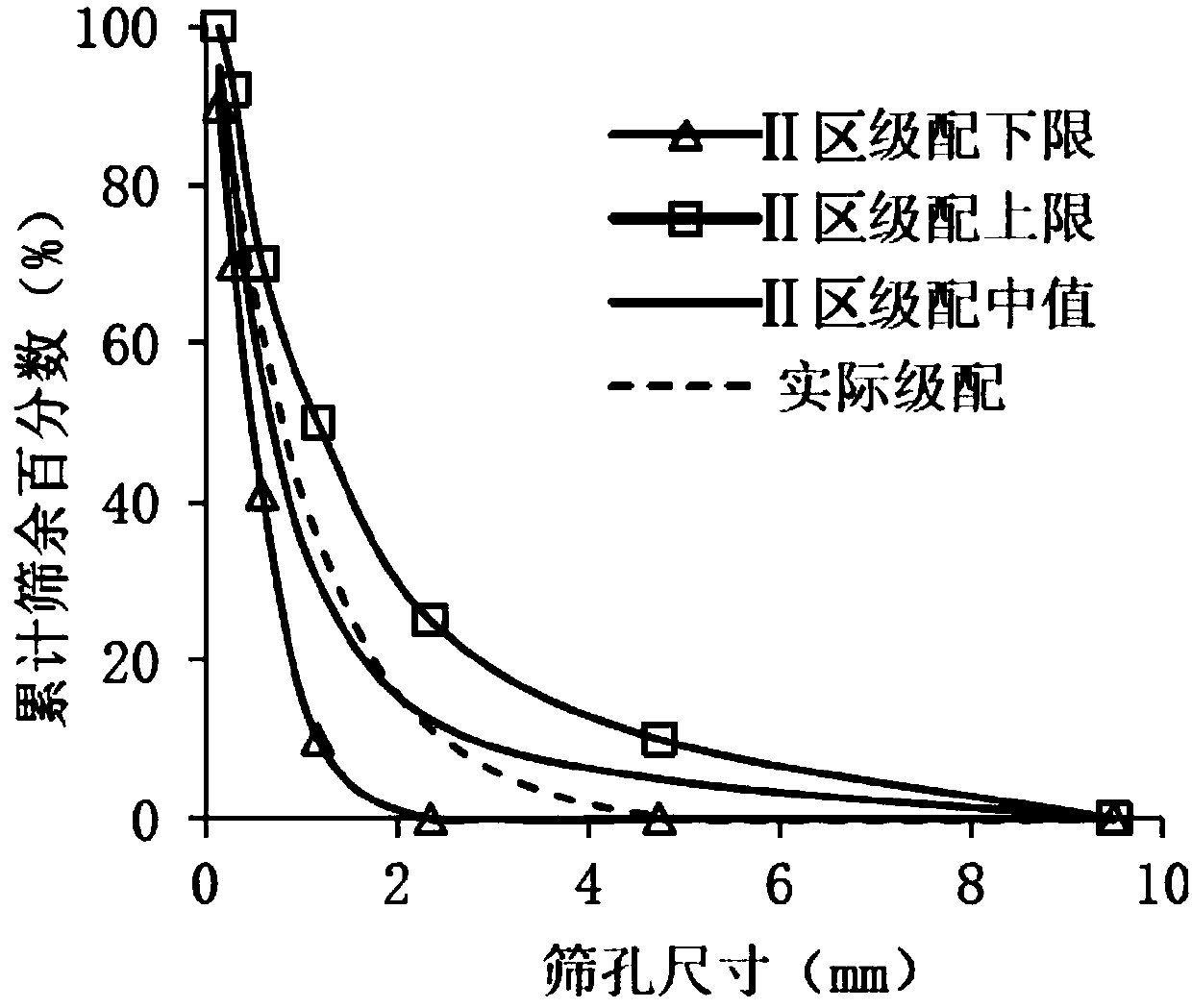

[0029] The machine-made sand used in this example is self-prepared from stones from Baotai mining quarry in Ruicheng County. Specifically, the stones are crushed by a jaw crusher and crushed stones with a particle size of 5-13mm are screened, and vertical shaft impact is used. The type crusher is used as a sand making machine to process the screened gravel into coarse sand, and then sieve the coarse sand with a particle size below 4mm to obtain the finished machine-made sand after dedusting by dry method. The finished machine-made sand has a fineness modulus of 2.8, a MB value of 1.2, a stone powder content of 6.7%, and an apparent de...

Embodiment 2

[0032] Take 431kg of PO42.5 cement, 85kg of fly ash, 653kg of machine-made sand, 1097kg of crushed stone with a particle size of 5-20mm, 4.7kg of water reducing agent and 165kg of water into a mixer and mix evenly to obtain about 40L. Apply to the corrugated rigid web box Beams of machine-made sand self-compacting concrete samples.

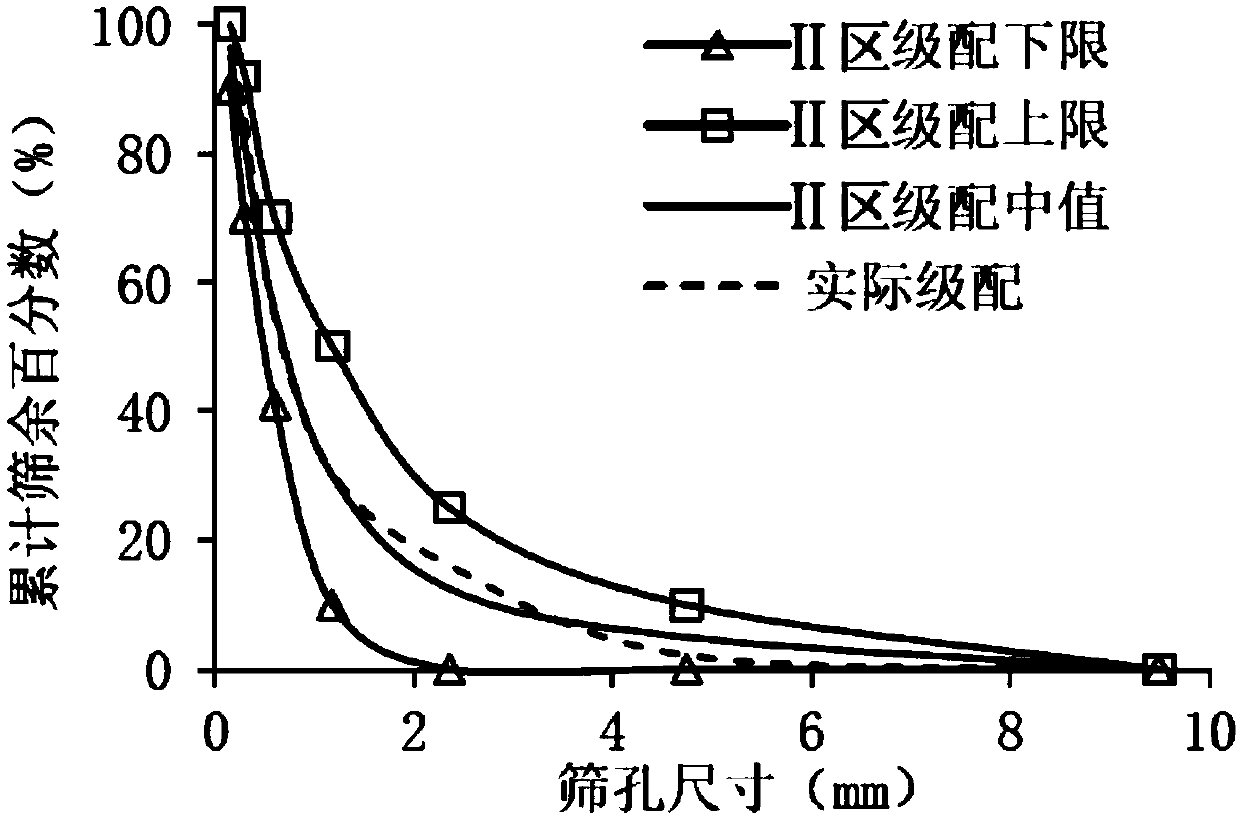

[0033] The machine-made sand used in this example is the machine-made sand produced by using the same source of raw materials as in Example 1 with the same equipment and methods. The fineness modulus of the finished machine-made sand is 2.7, the MB value is 1.0, and the stone powder content was 7.3%.

Embodiment 3

[0035] Take 442kg of PO42.5 cement, 82kg of fly ash, 637kg of machine-made sand, 1112kg of crushed stone with a particle size of 5-20mm, 5.1kg of water reducing agent and 165kg of water into a mixer and mix evenly to obtain about 40L. Apply to the corrugated rigid web box Beams of machine-made sand self-compacting concrete samples.

[0036] The machine-made sand used in this example is the machine-made sand produced by using the same source of raw materials as in Example 1 with the same equipment and methods. The fineness modulus of the finished machine-made sand is 2.9, the MB value is 0.7, and the stone powder The content is 6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com