PTFE tape numerical control film drawing machine

A technology of film stretching machine and raw material tape, which is applied in the direction of thin material processing, winding strips, and sending objects, etc., which can solve the problems of small number of stretched tapes, poor production quality, and insufficient time for degreasing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

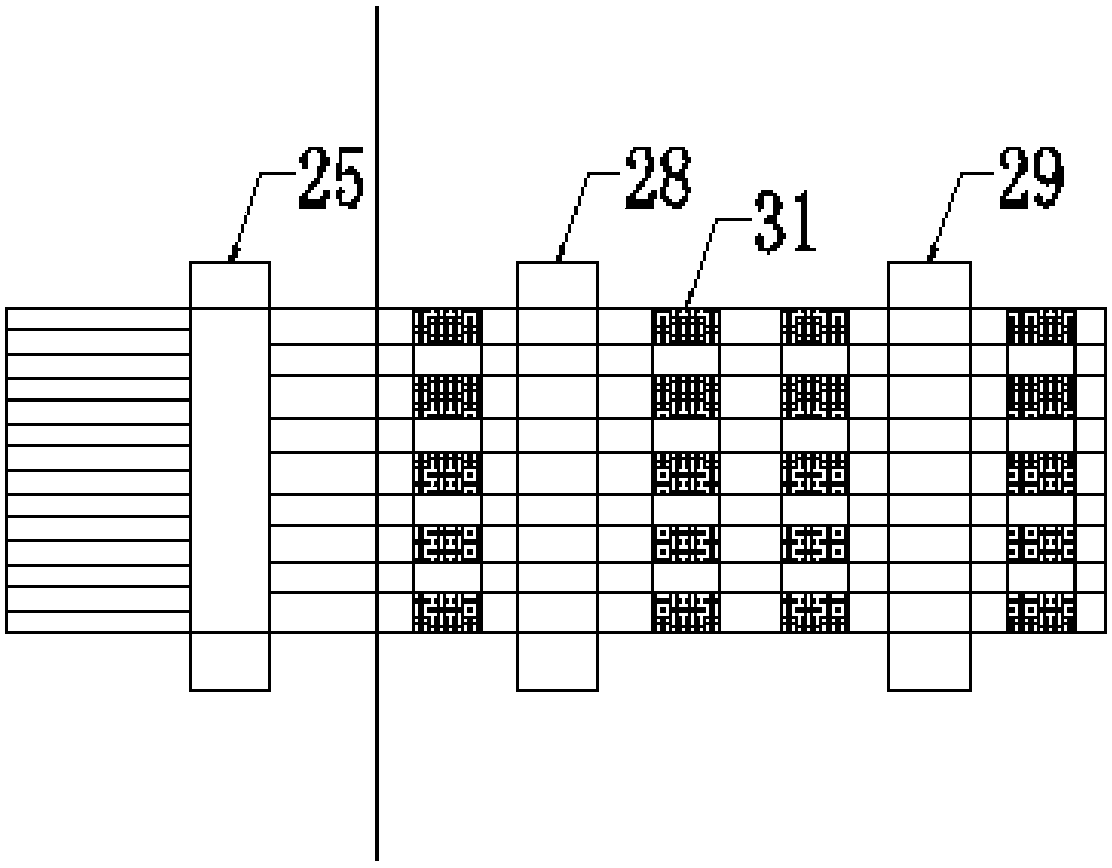

[0018] Such as Figure 1-2 As shown, a kind of PTFE raw material belt numerical control film drawing machine of the present invention comprises film drawing machine body 1, and film drawing machine body 1 comprises discharging device 3, heating stretching device 13, high temperature setting device 14, thickness measuring device 24 and Winding device 27, positioning shaft 4 is installed on one side of heating and stretching device 13, heating and stretching device 13 includes preheating part 9, first stretching part 10, second stretching part 11 and the third stretching part 12, preheating and stretching part 13 The hot part 9, the first stretching part 10, the second stretching part 11 and the third stretching part 12 are all driven by the first motor 6 through the first belt 7 to drive the first drive shaft 8, and the first drive shaft 8 passes through the raw material The belt 2 is connected to the driven shaft 5 provided on the upper end of the first drive shaft 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com