Novel feeding device

A feeding device and a new type of technology, applied in packaging, fuel supply, transportation and packaging, etc., can solve the problems of large space requirements for belt conveyors and rotary conveyors, heavy maintenance workload, and inconvenient maintenance, etc., to achieve Excellent operating environment, stable and controllable feeding amount, and not easy to bridge the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

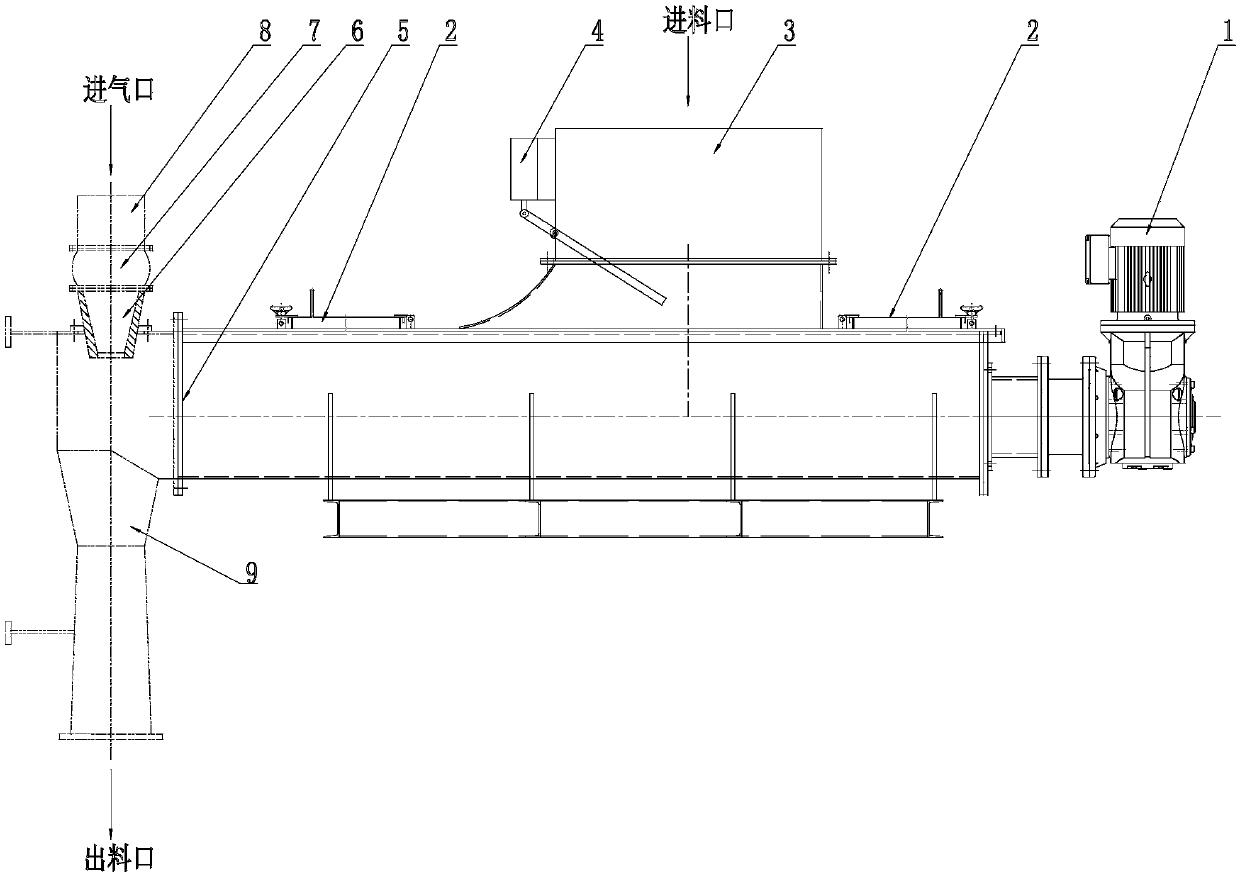

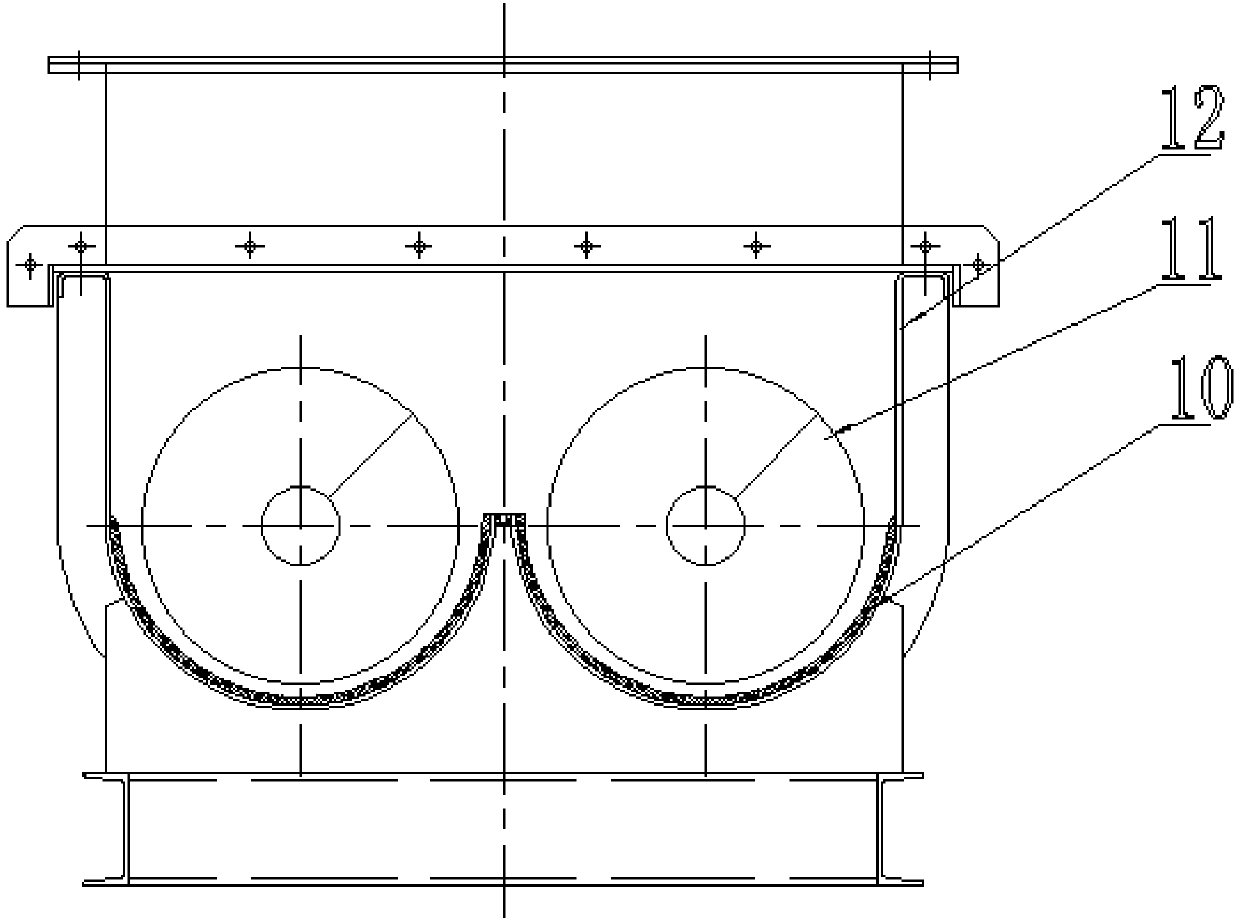

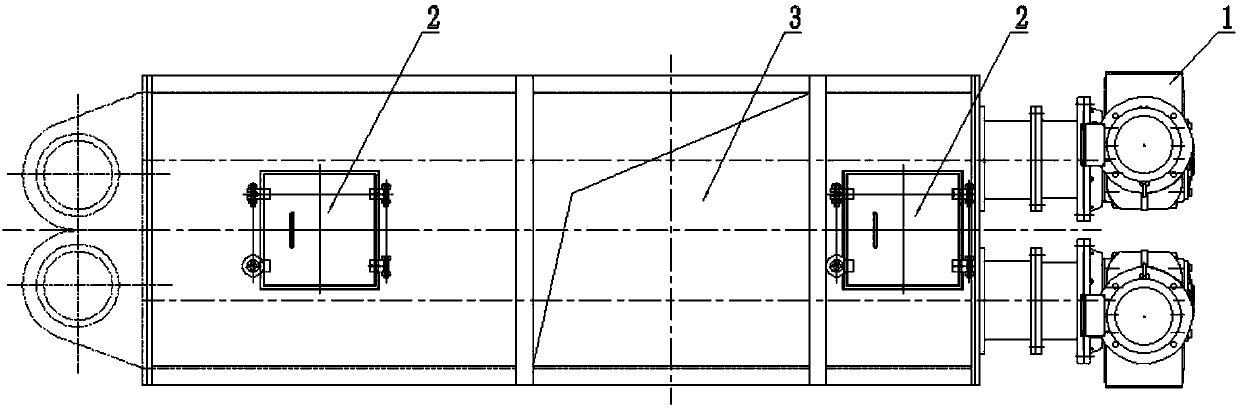

[0018] Such as figure 1 , figure 2 and image 3 As shown, a new feeding device provided by the present invention includes: a driving device 1, an inspection port 2, a feed port 3, an anti-bridging device 4, an adapter 5, a spout 6, a soft connection 7, and an air inlet 8 , pneumatic conveying pipe 9, wear-resistant layer 10, auger 11, housing 12, the driving device 1 provides power for the auger 11, the inspection port 2 and the feeding port 3 are arranged on the housing 12, the The anti-bridging device 4 is arranged on the feed inlet 3, the auger 11 is arranged inside the casing 12, the wear-resistant layer 10 is arranged under the auger 11, and the transfer port 5 is connected to the outlet of the auger 11 and the pneumatic conveying The material receiving port of the pipe 9, the nozzle 6 is arranged above the pneumatic conveying pipe 9, and the flexibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com