Unit coils intermeshed anti-tear fabric

A technology of unit coils and fabrics, which is applied in the field of textile fabrics and fabrics, can solve the problems that fabrics cannot be light, tear-resistant, poor air permeability, and heavy weight, and achieve high strength, good softness, and strong chemical corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

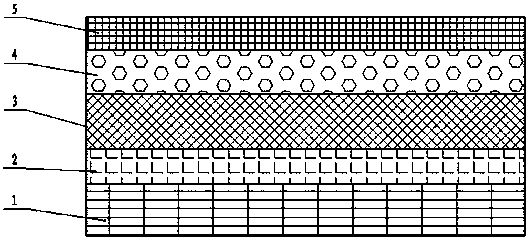

[0015] see figure 1 , a tear-resistant fabric with unit coils interspersed with each other, including an inner fiber layer, an intermediate composite layer, a fabric layer, a base layer and a tear-resistant layer are sequentially arranged outside the inner fiber layer, and each layer is fixed by sewing; the inner fiber layer A layer includes a first warp yarn and a first weft yarn, the first warp yarn is woven with cotton fibers, and the first weft yarn is woven with flax fibers; the intermediate composite layer includes a second warp yarn and a second weft yarn, and the second The warp yarn is woven with denim yarn, the second weft yarn is woven with metal wire spiral fiber; the fabric layer includes a third warp yarn and a third weft yarn, the third warp yarn is woven with modal fiber, and the third weft yarn The base layer is woven with cotton fiber; the base layer is woven with CoolMaX DuPont moisture-absorbing and breathable polyester fiber; the tear-resistant layer is wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com