Anti-pull artificial leather of which unit coils are interlooped

A unit coil and artificial leather technology, applied in the field of artificial leather, can solve problems such as easy breakage, poor tensile performance, and performance that cannot meet quality requirements, and achieve the effect of not easy to break, increase tensile performance, good elasticity and tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

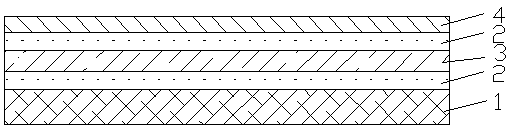

[0010] see figure 1 , the present invention relates to a kind of unit coil interlaced tensile artificial leather, which is composed of substrate layer 1, adhesive layer 2, reinforcement layer 3, adhesive layer 2 and surface layer 4 from bottom to top, and the reinforcement layer 4 Composed of textiles and fibers. The matrix layer is composed of the following raw materials in parts by weight: 36-45 parts of polyvinyl chloride resin; 18-26 parts of plasticizer; 8-14 parts of toughening agent; 0.8-1.7 parts of stabilizer; 9-15 parts of filler ; 2~4 parts of soybean oil; 0.3~0.9 parts of lubricant; 0.5~1.1 parts of black paste.

[0011] A lining fabric layer is compounded on the back of the substrate layer, and the lining fabric layer is a kind of knitted fabric formed by interlocking continuous unit coils, and the continuous unit coils are made of stainless steel fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com