HSM manufacturing process for arm rod of carbon fiber mechanical arm

A manufacturing process, carbon fiber technology, applied in the HSM manufacturing process field of the boom, can solve the problems of poor bonding between fiber layers, increased equipment investment, and large equipment investment, so as to overcome the defective rate of products, improve the yield rate of products, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

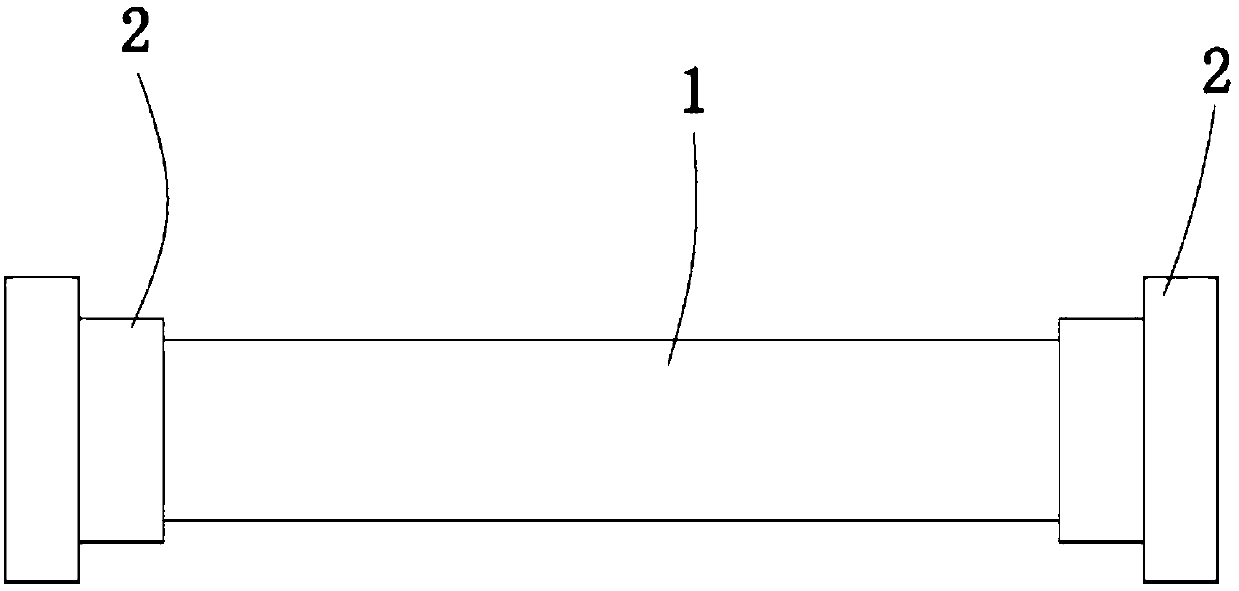

[0034] Embodiment 1: The preparation process of the arm bar of carbon fiber manipulator

[0035] 1) Cutting high-energy glue, fiber prepreg and pre-embedded pipe;

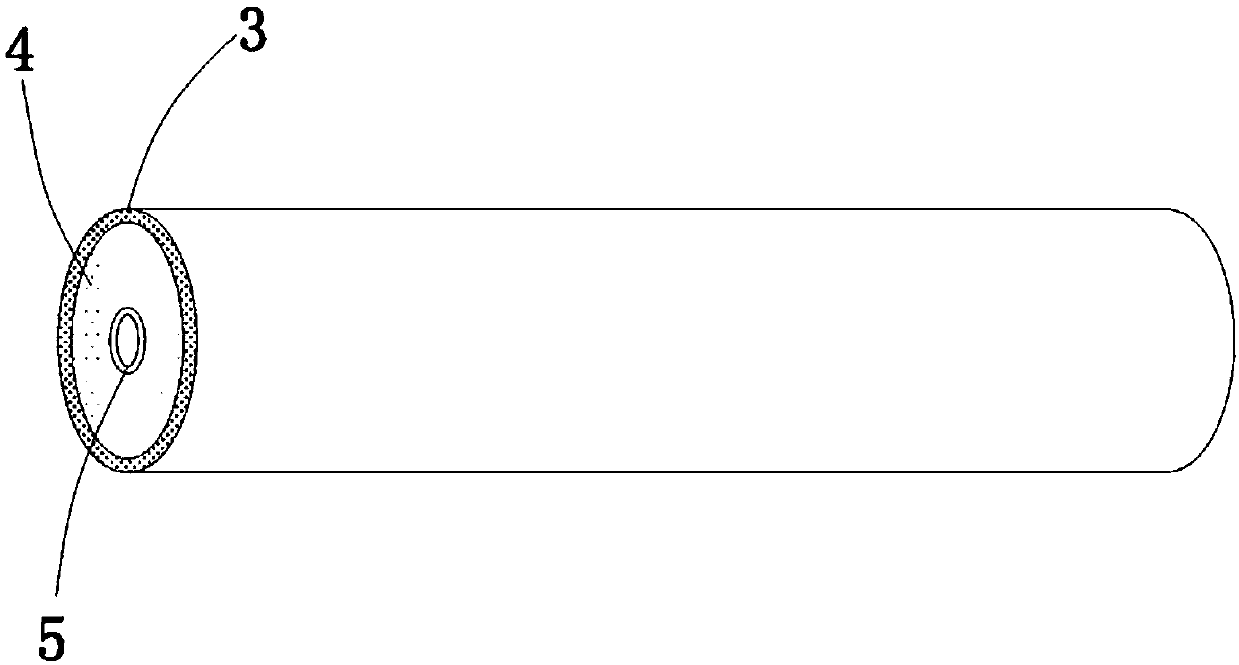

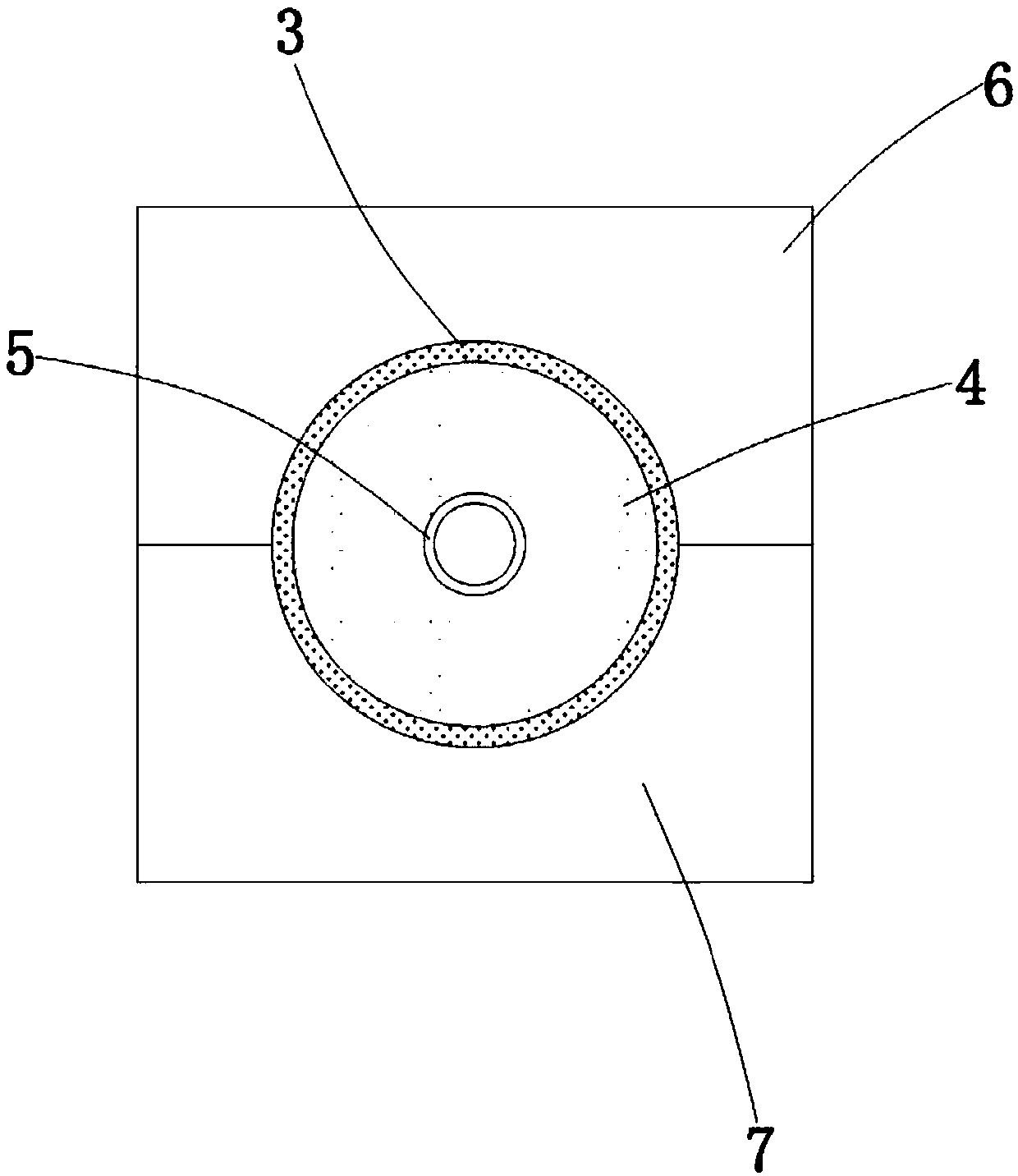

[0036] 2) Put the pre-embedded tube wrapped with thermal self-expanding high-energy adhesive into the core material mold, heat to 80°C, and maintain for 15 minutes. At this temperature, the thermal self-expanding high-energy adhesive pre-expands slightly to fill the cavity of the core material, and then cool and demould removal of preformed core material;

[0037] 3) Wrap the fiber prepreg cloth around the preformed core material to obtain the preformed part, put it into the forming mold, close the mold and heat it to the forming temperature of 150°C, and the forming time is 15 minutes; cooling, demoulding, and taking out the part, that is Obtain the arm rod of the carbon fiber robotic arm.

[0038] The fiber prepreg is carbon fiber prepreg.

[0039] The embedded pipe may be a plastic pipe, a carbon fiber compos...

Embodiment 2

[0041] Embodiment 2: The preparation process of the arm bar of carbon fiber manipulator

[0042] 1) Cutting high-energy glue, fiber prepreg and pre-embedded pipe;

[0043] 2) Put the pre-embedded tube wrapped with thermal self-expanding high-energy adhesive into the core material mold, heat to 100°C, and maintain for 3 minutes. At this temperature, the thermal self-expanding high-energy adhesive pre-expands slightly to fill the cavity of the core material, and then cool and demould removal of preformed core material;

[0044] 3) Wrap the fiber prepreg cloth around the preformed core material to obtain the prefabricated part, put it into the forming mold, close the mold and heat it to the forming temperature of 120°C, and the forming time is 60 minutes; cooling, demoulding, and taking out the part, that is Obtain the arm rod of the carbon fiber robotic arm.

[0045] The fiber prepreg is carbon fiber prepreg.

[0046] The embedded pipe may be a plastic pipe, a carbon fiber co...

Embodiment 3

[0051] Embodiment 3: the preparation process of the arm bar of carbon fiber manipulator

[0052] 1) Cutting high-energy glue, fiber prepreg and pre-embedded pipe;

[0053] 2) Put the pre-embedded tube wrapped with thermal self-expanding high-energy adhesive into the core material mold, heat to 90°C, and maintain for 30 minutes. At this temperature, the thermal self-expanding high-energy adhesive pre-expands slightly to fill the cavity of the core material, and then cool and demould removal of preformed core material;

[0054] 3) Wrap the fiber prepreg cloth around the preform core material to obtain the preform, put it into the forming mold, close the mold and heat to the forming temperature of 180°C, and the forming time is 10 minutes; cooling, demoulding, and taking out the part, that is Obtain the arm rod of the carbon fiber robotic arm.

[0055] The fiber prepreg is carbon fiber prepreg.

[0056] The embedded pipe may be a plastic pipe, a carbon fiber composite pipe or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com