Small-diameter precision blind hole machining method

A processing method and small-diameter technology, applied in the field of mechanical processing, can solve problems such as hole diameter out-of-tolerance, achieve the effects of improving processing quality, ensuring hole position accuracy, and avoiding drill bit swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

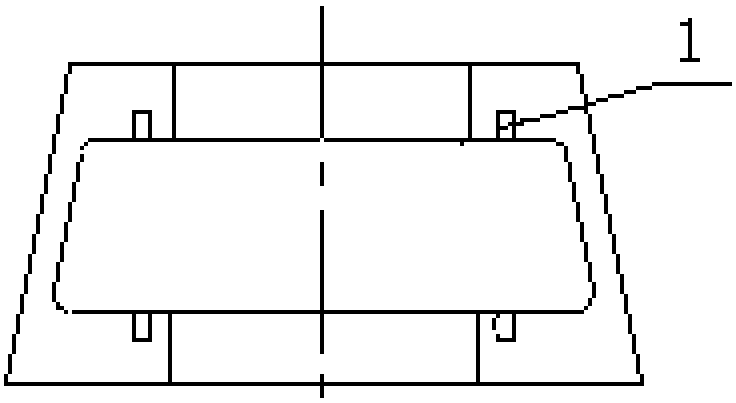

[0031] Example 1, see Figure 1a~1b , the schematic diagram of the structure of the aero-engine linkage half-ring, there are two T-shaped ring grooves with a width of 2 mm on the upper and lower ends of the annular groove of the half-ring, and two diameters are designed in the middle of the joint surface 2 of the half-ring and the T-shaped groove. φ3mm, 3mm deep blind hole 1.

[0032] The processing method is as follows:

[0033] 1) Countersink: use a φ2.8mm countersink (milling cutter) to countersink, and the depth of the countersink is 3.4mm;

[0034] 2) Boring: Boring diameter ф2.9mm, boring depth 3.3mm;

[0035] 3) Test reaming: Trial cutting on the test piece of the same material, and eliminate the over-tolerance of the aperture size caused by the out-of-tolerance of the diameter of the reamer;

[0036] 4) Reaming: use a reamer that has been tested for reaming, and the reaming depth is 3.2mm;

[0037] 5) Measure the pore diameter, using an inner dial gauge to measure ...

Embodiment 2

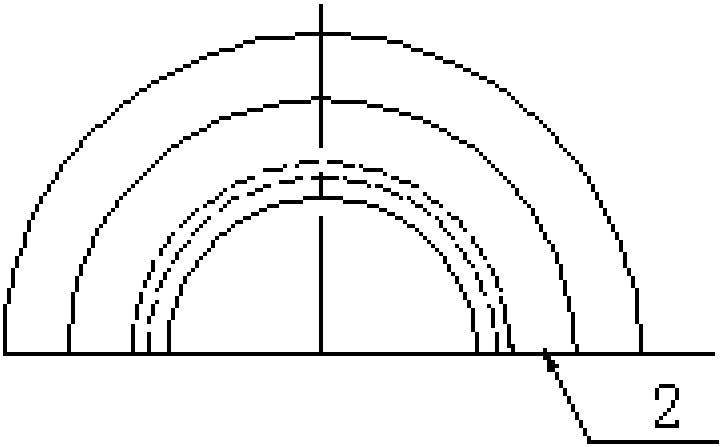

[0038] Example 2, see Figure 2a-2b , the schematic diagram of the blind hole structure in the inner casing of the aero-engine, there is an annular end face groove 3 with a width of 2.32mm designed on the large end face of the casing, and there are four blind holes 1 of φ3mm distributed in the middle of the annular end face groove 3. There are also 16 φ5mm holes designed on the side of the big end.

[0039] The processing method is as follows:

[0040] 1) Countersink: use a φ2.8mm countersink to countersink, and the depth of the countersink is 3.4mm;

[0041] 2) Boring: Boring diameter φ2.9mm, boring depth 3.3mm;

[0042] 3) Trial reaming: Trial cutting at the position of the φ5mm hole on the end surface of the part, and eliminate the out-of-tolerance hole size caused by the out-of-tolerance diameter of the reamer;

[0043] 4) Reaming: use a reamer that has been tested for reaming, and the reaming depth is 3.2mm;

[0044] 5) Measure the pore diameter, using an inner dial g...

Embodiment 3

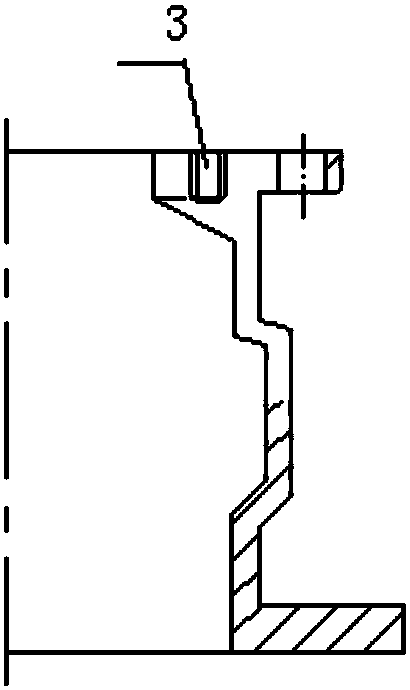

[0045] Example 3, see Figure 3a~3c , a schematic diagram of the blind hole structure of the aero-engine compressor casing, the casing includes the upper half 4 and the lower half 5, in the middle of the T-shaped slot on the joint surface 6 of the upper half 4 of the casing, one φ3 needs to be processed +0. 015mm, depth 3 +0.5 The blind hole 1.

[0046] The processing method is as follows:

[0047] 1) Countersink: use a φ2.8mm countersink (milling cutter) to countersink, and the depth of the countersink is 3.4mm;

[0048] 2) Boring: Boring diameter φ2.9mm, boring depth 3.3mm;

[0049] 3) Test reaming: Trial cutting on the test piece of the same material, and eliminate the over-tolerance of the aperture size caused by the out-of-tolerance of the diameter of the reamer;

[0050] 4) Reaming: use a reamer that has been tested for reaming, and the reaming depth is 3.2mm;

[0051] 5) Measure the pore diameter, using an inner dial gauge to measure the pore diameter.

[0052] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com