Processing method for low-gear support plate of gearbox

A processing method and support plate technology, applied in metal processing equipment, metal processing mechanical parts, supports, etc., can solve problems such as inability to meet the requirements of 0.15mm, low processing efficiency, etc., to reduce production costs and meet customer requirements. needs, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings, but this embodiment should not be construed as limiting the present invention.

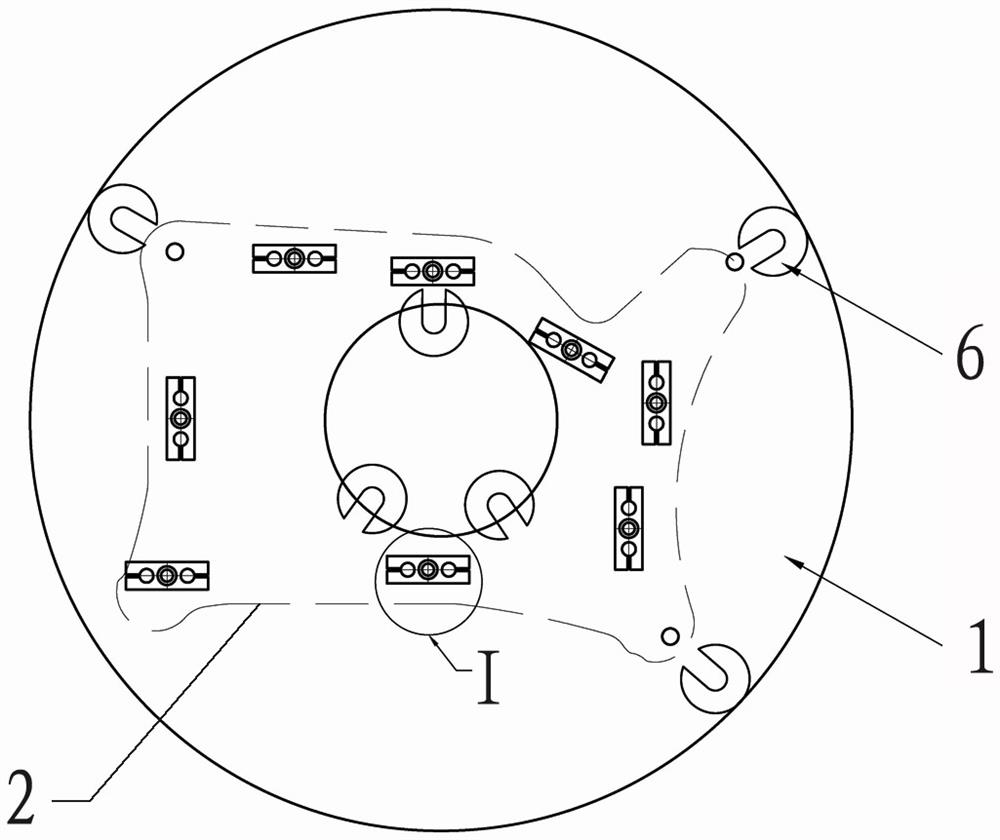

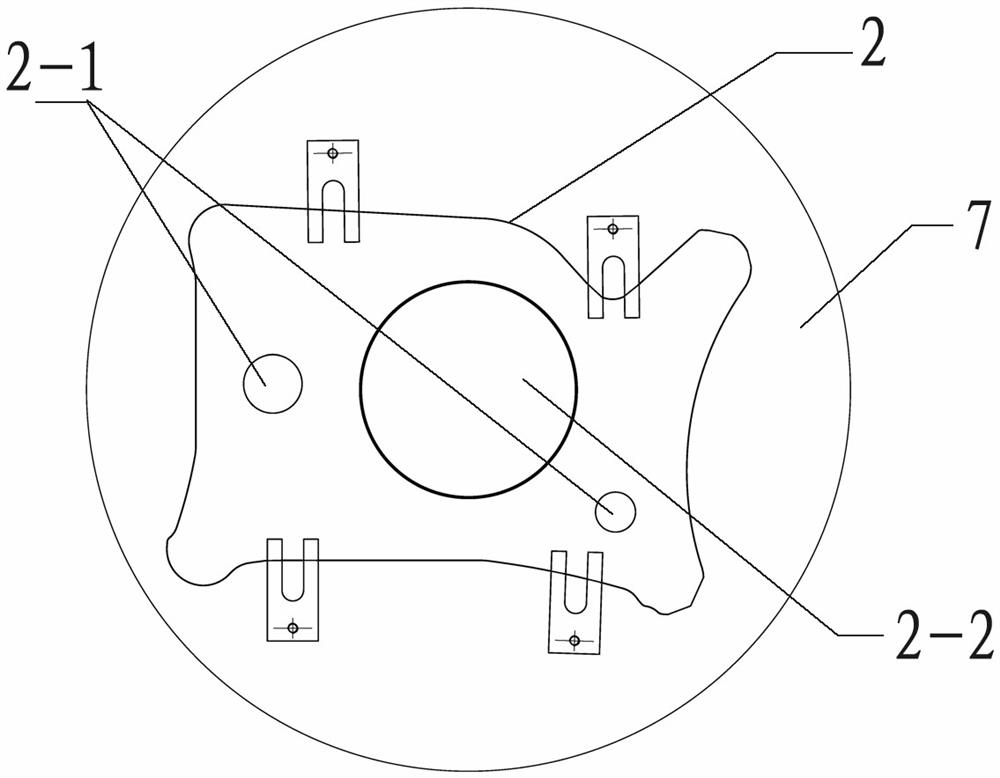

[0019] The present invention as Figure 1 to Figure 4 Shown:

[0020] A method for processing a low-gear support plate of a gearbox, comprising the following steps:

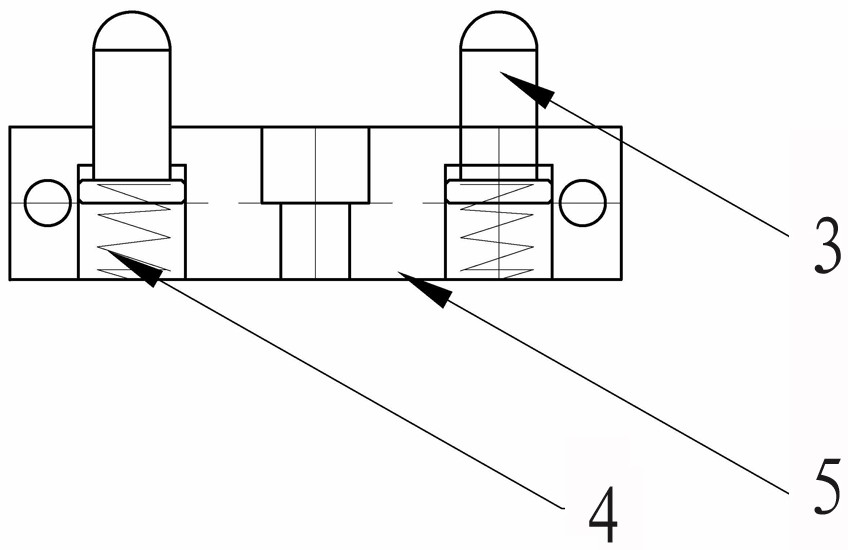

[0021] S1, one of the end faces of the finish car: place the blank plate 2 that has been cut and has an inner hole 2-2 on the floating locking support mechanism. The cylindrical pin 3 set in the direction, the cylindrical pin passes through the spring installation cavity, the lower end of the cylindrical pin is provided with a limit boss and abuts against the upper end of the spring one 4, the spring installation cavity is set in the insert 5, and the insert is fixed on On the positioning plate 1, the cylindrical pin 3 forms a support for the bottom surface of the blank plate 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com