Automatic loading and unloading device for metal mold casting

A technology of automatic loading and unloading and metal molds, which is applied to equipment for feeding molten metal into molds, casting workshops, casting equipment, etc., can solve problems such as high temperature of liquid metal, easy production accidents, and rising labor costs Reduce the cycle, occupy a small volume, and have good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

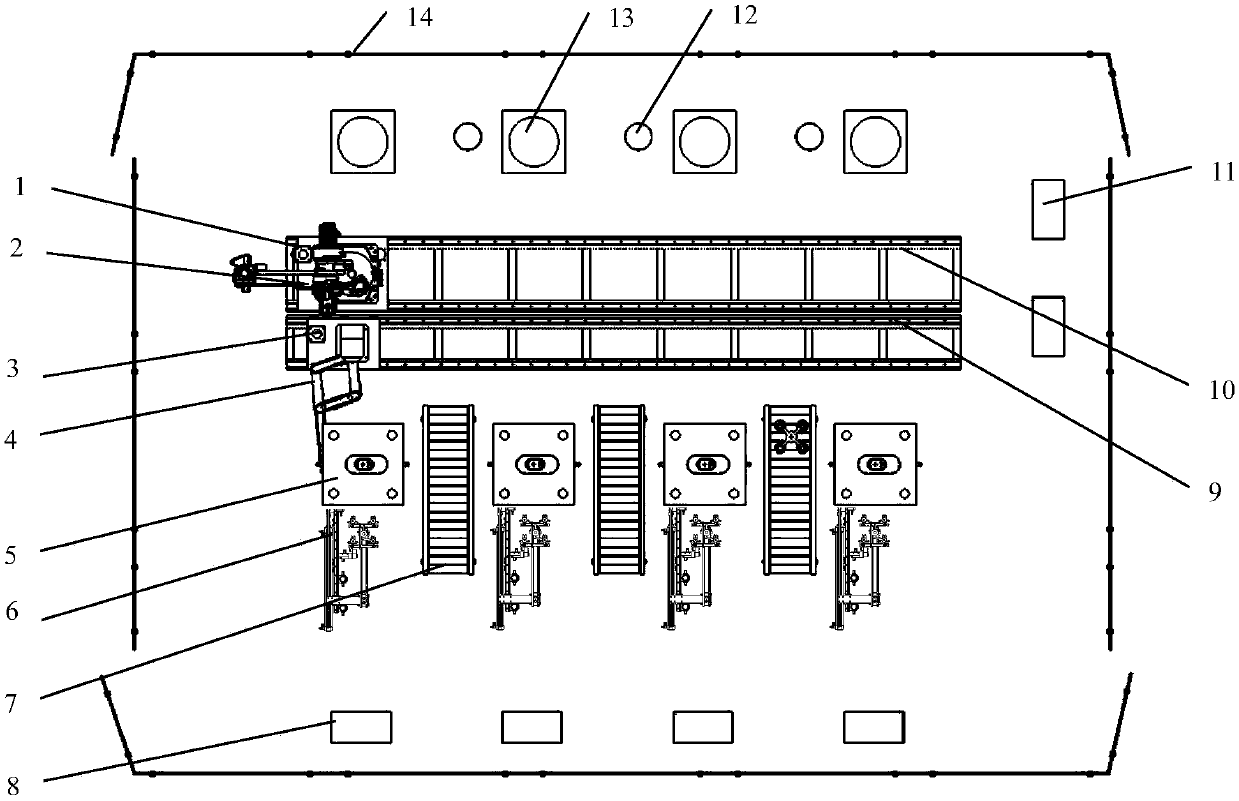

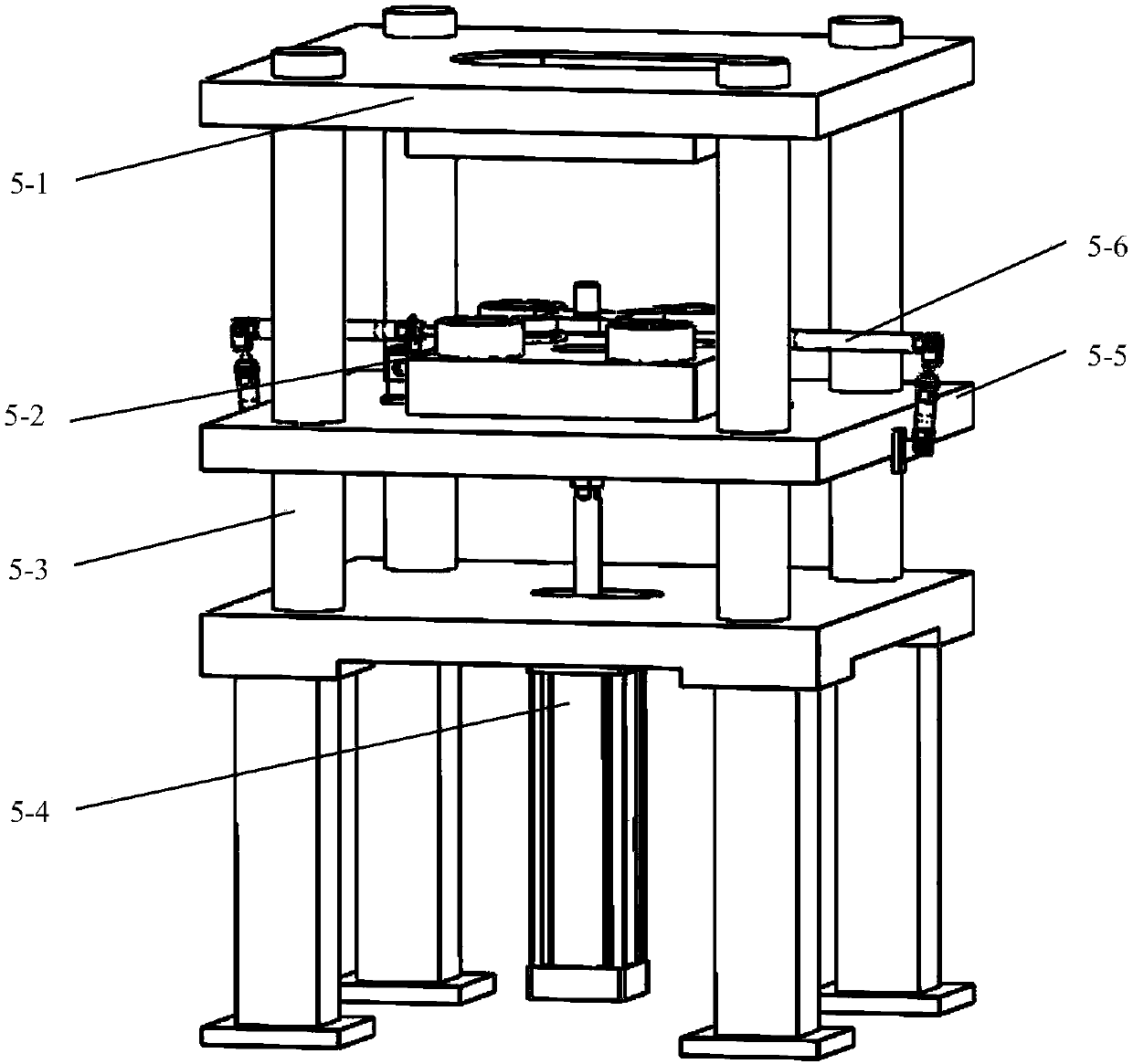

[0025] Such as Figure 1-Figure 7 As shown, an automatic loading and unloading device for metal mold casting, including a stacking robot 2, a first sliding mechanism 1, a planar joint robot 4, a second sliding mechanism 3, four pouring machines 5, and four automatic mold release agents The mechanism 6 and three output lines 7, the palletizing robot 1 and the planar joint robot 2 are set between the metal melting furnace 3 and the pouring machine 5, and the output line 6 is set on one side of the pouring machine 5.

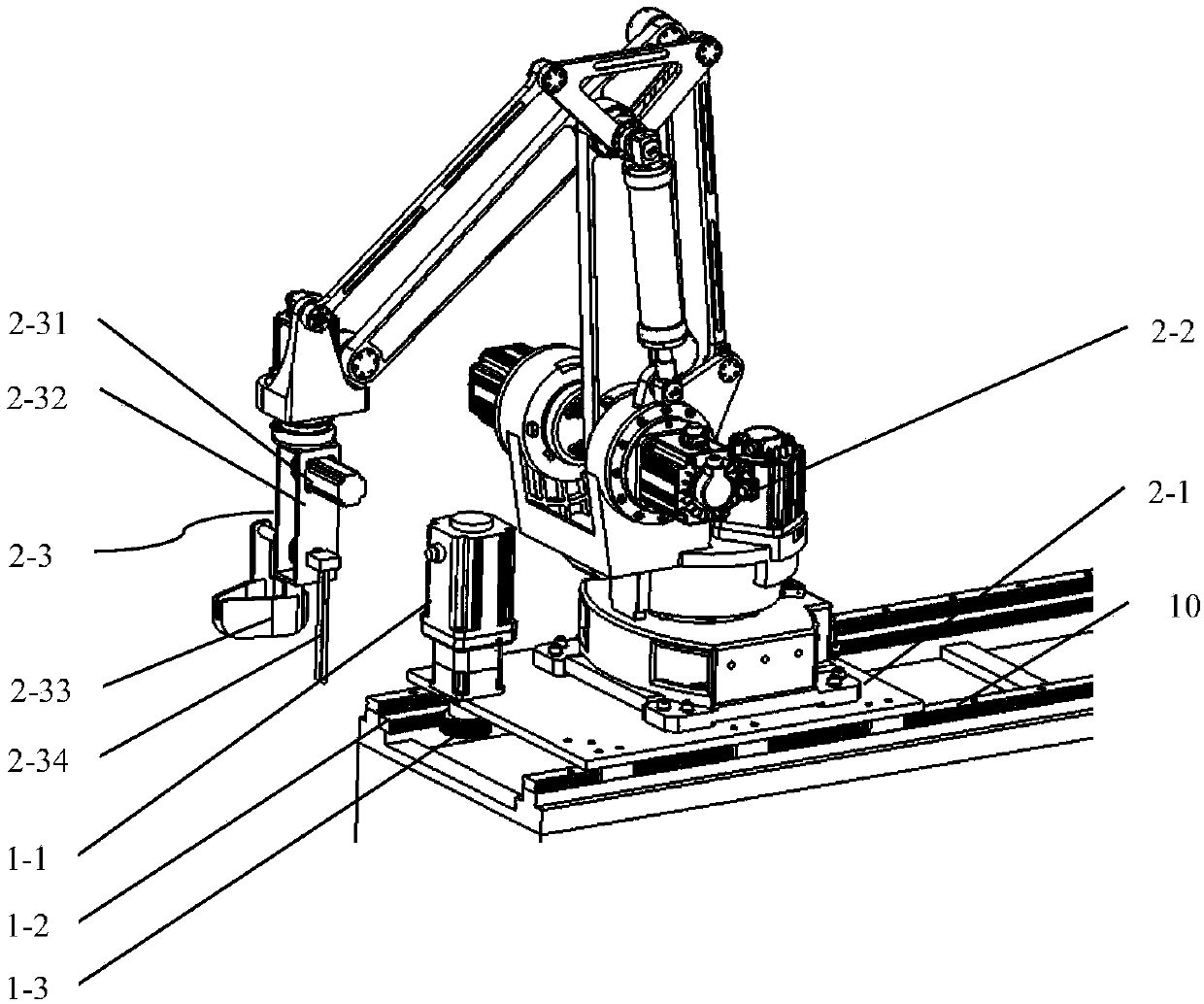

[0026] Palletizing robot 2 comprises first slide plate 2-1, stacking robot body 2-2 and pouring gripper 2-3, and stacking robot body 2-2 is installed on the first slide plate 2-1, and stacking robot body 2-2 has three degrees of freedom of movement and one degree of freedom of rotation. The pouring gripper 2-3 includes a protective cover 2-32, a first motor 2-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com