Electromagnetic heating cooker, control method and control device thereof

A control method and technology of a control device, which are applied to electric heating devices, induction heating control, induction heating devices, etc., can solve the problems of resonant circuit 3 vibration stop, heating, and comparator E output inversion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

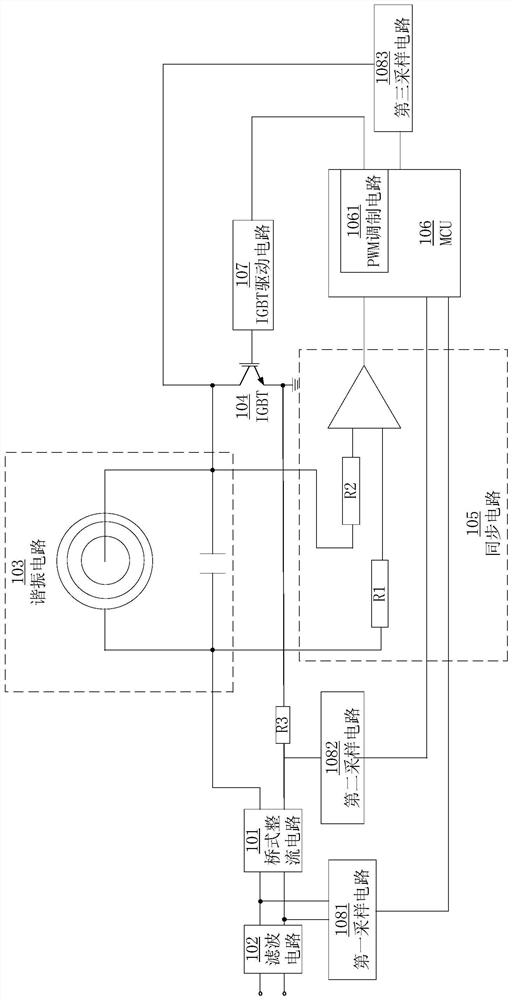

[0046] The induction cooker of this embodiment includes: a resonant circuit and an IGBT. The IGBT forms an electromagnetic oscillation circuit together with the resonant circuit and an external power supply (mains power), so that a high-frequency magnetic field change is generated by the mutual cooperation of the coil disk and the capacitor in the resonant circuit. , and then a magnetic field vortex is formed between the induction cooker and the pot, causing the vibration of metal atoms in the pot, causing the pot to heat up, thereby achieving the purpose of heating the food.

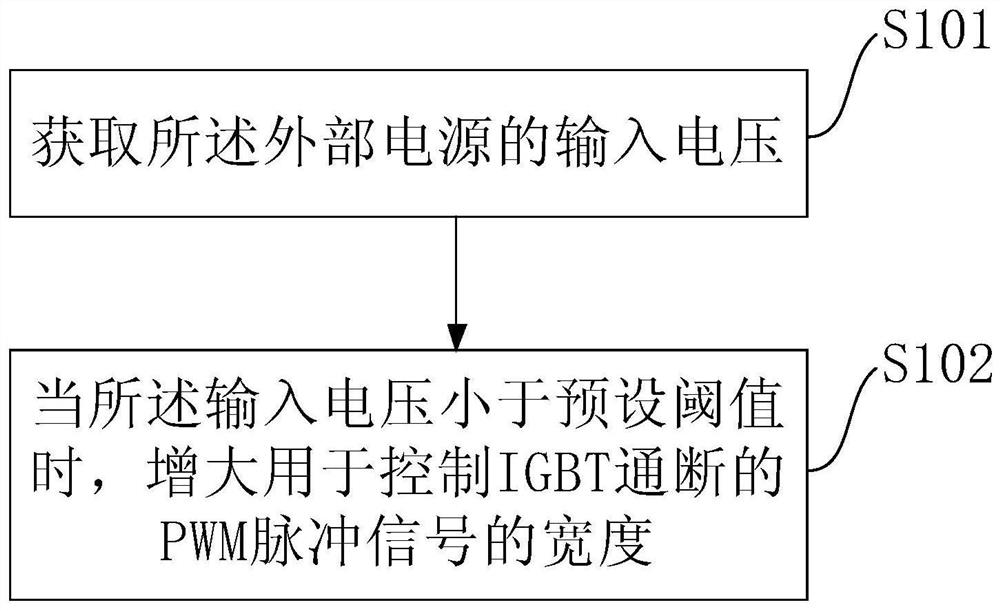

[0047] figure 2 This is a schematic flowchart of the control method provided in this embodiment. like figure 2 As shown, the control method of this embodiment includes:

[0048] S101. Obtain the input voltage of the external power supply.

[0049] In the actual environment, obtaining the input voltage of the external power supply can be achieved by various methods. for example:

[0050] In some o...

Embodiment 2

[0074] The induction cooker of this embodiment includes: a resonant circuit and an IGBT. The IGBT forms an electromagnetic oscillation circuit together with the resonant circuit and an external power supply (mains power), so that a high-frequency magnetic field change is generated by the mutual cooperation of the coil disk and the capacitor in the resonant circuit. , and then a magnetic field vortex is formed between the induction cooker and the pot, causing the vibration of metal atoms in the pot, causing the pot to heat up, thereby achieving the purpose of heating the food.

[0075] Figure 4 It is a schematic structural diagram of the control device 200 provided in this embodiment. like Figure 4 As shown, the control apparatus 200 of this embodiment can execute the control method of Embodiment 1, which includes: a first sampling module 202 and a processing module 201 electrically connected to the first sampling module 202 . Wherein, the first processing module 201 is use...

Embodiment 3

[0089] The induction cooker of this embodiment includes: a resonant circuit and an IGBT. The IGBT forms an electromagnetic oscillation circuit together with the resonant circuit and an external power supply (mains power), so that a high-frequency magnetic field change is generated by the mutual cooperation of the coil disk and the capacitor in the resonant circuit. , and then a magnetic field vortex is formed between the induction cooker and the pot, causing the vibration of metal atoms in the pot, causing the pot to heat up, thereby achieving the purpose of heating the food.

[0090] Figure 5 It is a schematic structural diagram of the control device 300 provided in this embodiment. like Figure 5 As shown, the control device 300 in this embodiment includes: a memory 302 storing an executable instruction set, and a processor 301 . The processor 301 is configured to invoke the executable instruction set in the memory 302 to execute the control method in the first embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com