Accumulated carbon self-cleaning method of spark plug

A self-cleaning, spark plug technology, applied in spark plug manufacturing and other directions, to shorten the development cycle, improve spark plug carbon deposition, and improve development efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

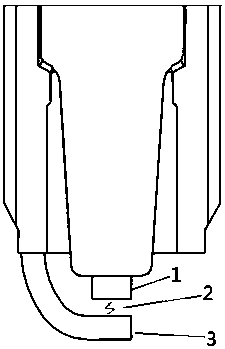

[0021] Such as figure 1 As shown, the schematic diagram of spark plug discharge in the case of no carbon deposition, the arc 2 breaks down from the center electrode 1 to the side electrode 3 during normal discharge.

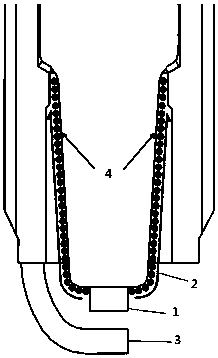

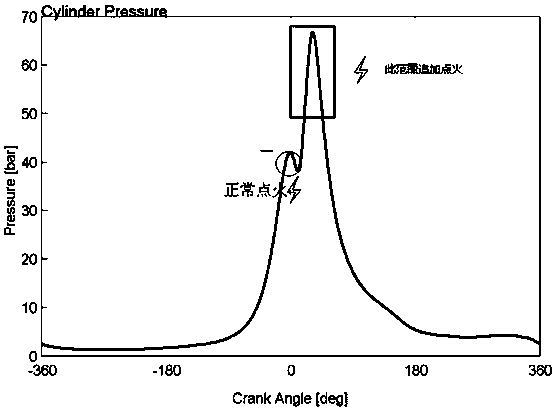

[0022] Such as Figure 2 to Figure 4 As shown in the self-cleaning method of spark plug carbon deposition, at the initial stage of engine start, the ignition coil is normally ignited in the engine compression stroke. The magnetization time is t; when reaching the engine working stroke, the ignition coil finishes magnetizing during the engine working stroke, and additional ignition is added. In the initial stage of starting, the number of additional ignition times i performed for each power stroke is determined according to the actual situation, and can be greater than 1 time.

[0023] If the performance of the spark plug is normal and there i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com