Automatic scanning device for welding seam of positioning plate of heat exchanger water chamber in nuclear power plant

A technology of heat exchanger and scanning device, which is applied in nuclear power generation, nuclear engineering, greenhouse gas reduction, etc., can solve the problems of unfavorable comparison and tracking inspection of nuclear power plants, difficult quality supervision during the inspection process, and great influence on the inspection process. Achieve the effect of reducing the risk of irradiation, improving stiffness, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

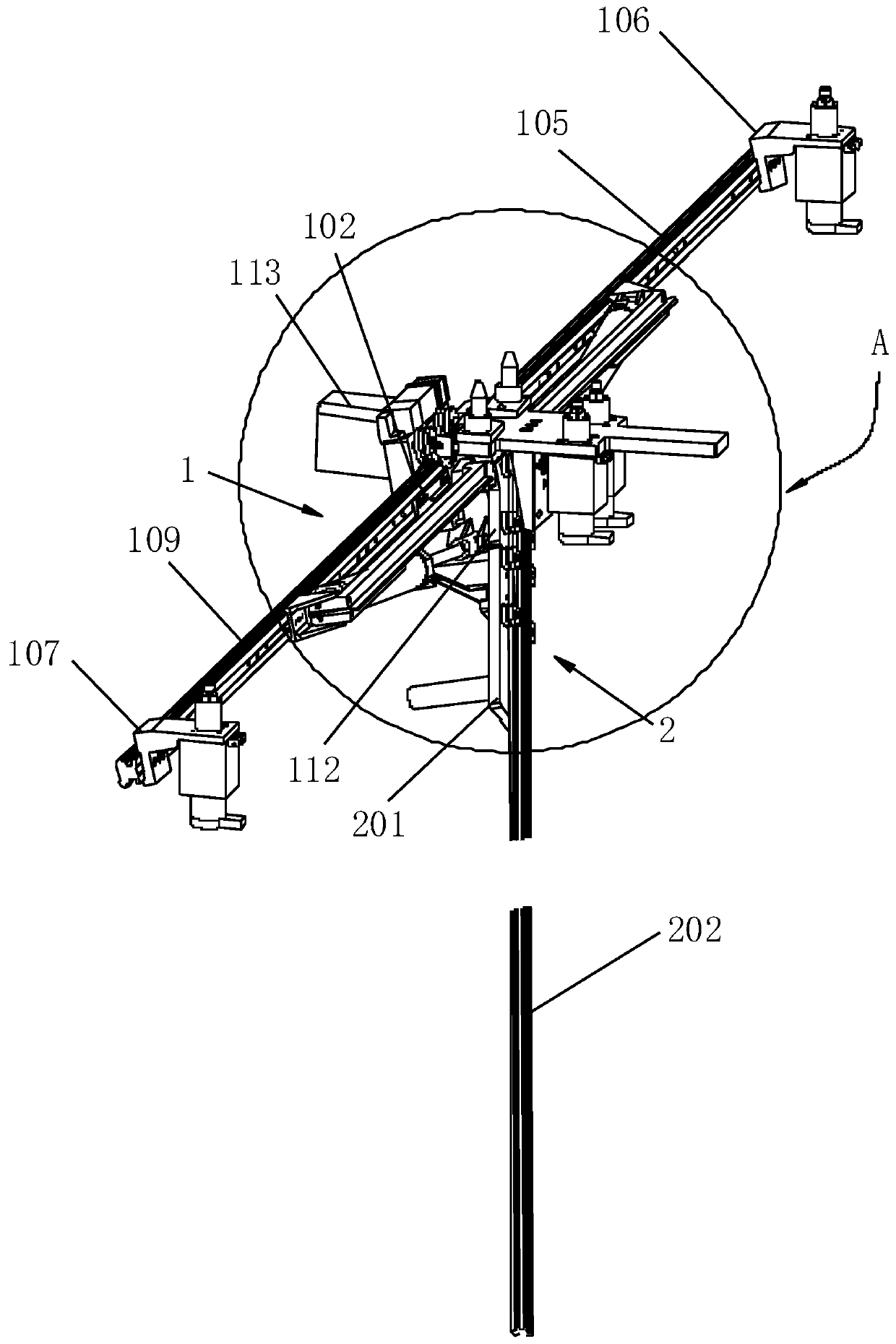

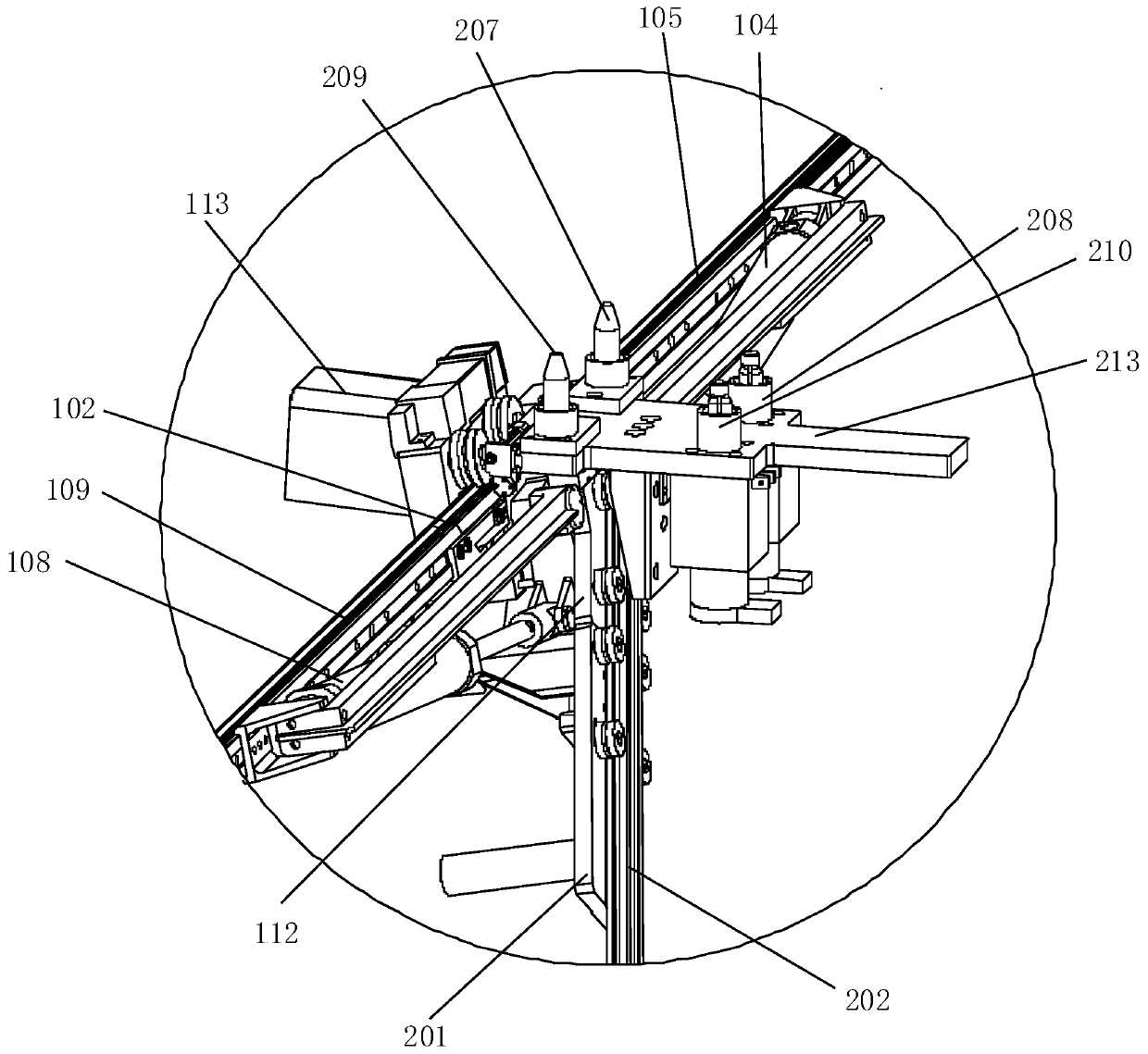

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

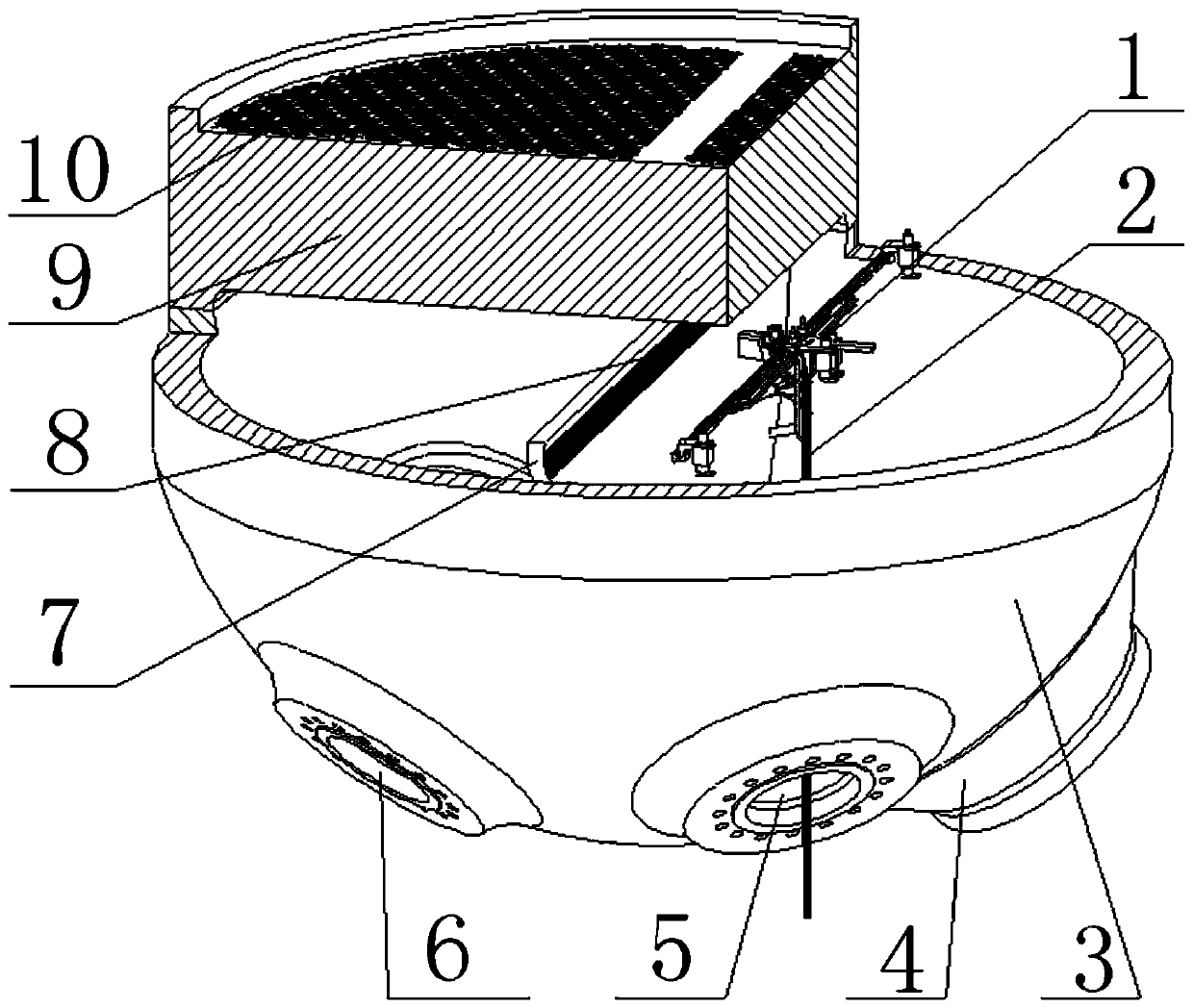

[0042] Such as figure 1 As shown, the heat exchanger water chamber of a nuclear power plant includes a hemispherical heat exchanger lower head 3, which forms a heat exchanger water chamber inside the heat exchanger lower head 3, and a positioning plate 7 is arranged in the water chamber, and the positioning plate 7 will The water chamber is divided into two chambers, the cold side and the hot side. There are welds 8 on both sides of the positioning plate 7. The cold side chamber is provided with a cold end manhole 6 and a cold end main pipe (not shown in the figure). The hot-side chamber is provided with a hot-end manhole 5 and a hot-end main pipe 4, and the upper top surface cover of the lower head of the exchanger 3 is provided with a heat exchanger tube plate 9, and the heat exchanger tube plate 9 is densely covered with heat exchange tubes. 10. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com