Collaborative navigation optimization method for fixed type assembling processes

A technology of assembly process and collaborative navigation, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of long optimization time, lack of models, lack of models, etc., to achieve the effect of improving transparency and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

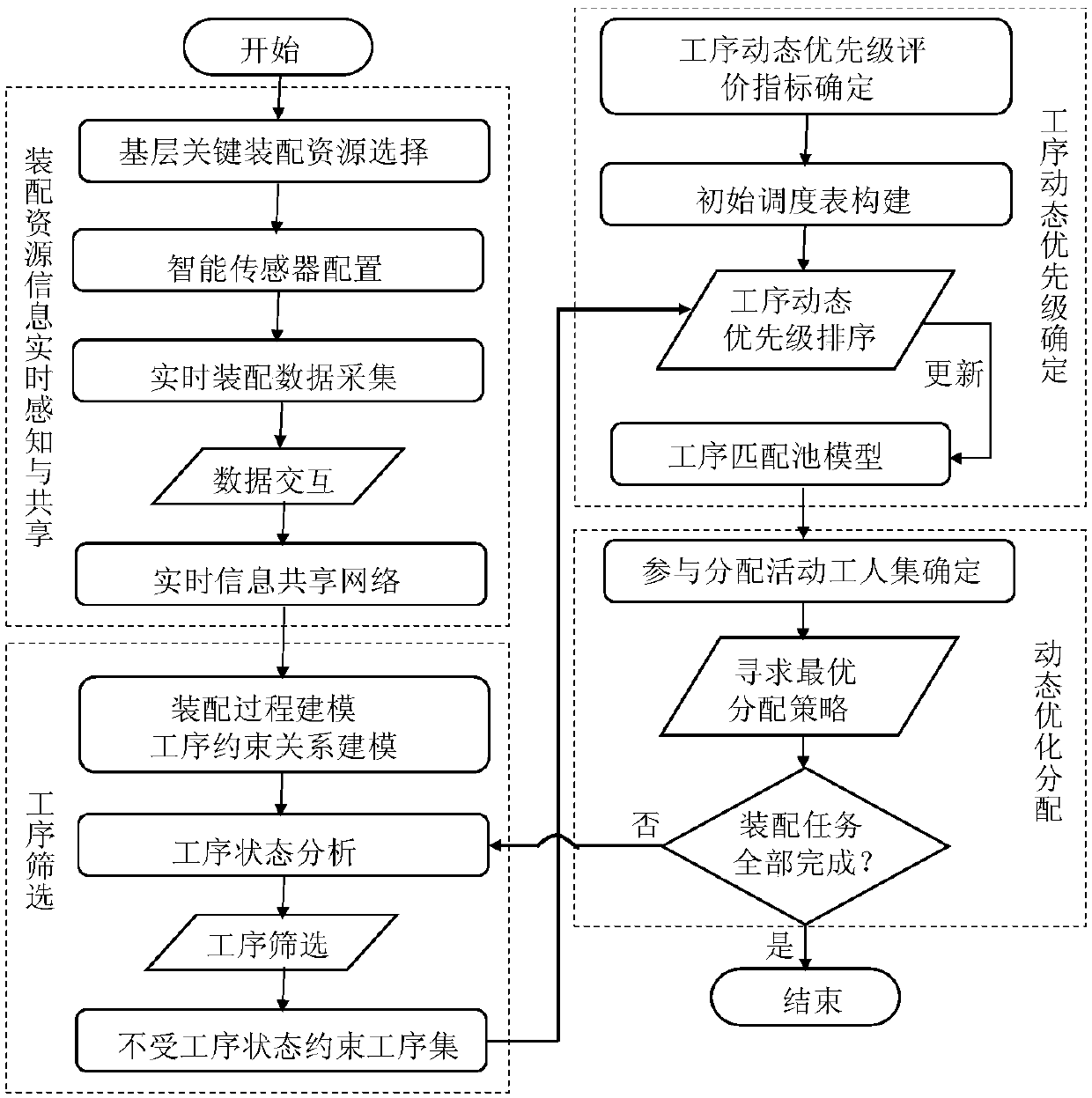

[0055] refer to figure 1 , the present invention provides a collaborative navigation optimization method oriented to a fixed assembly process, with the purpose of providing a real-time data-driven collaborative optimization method for a workshop assembly system. When an abnormality comes, the system can actively perceive the type and cause of the abnormality, and reduce the impact of the abnormality on the entire assembly system through the real-time collaborative optimization and matching process again and again. The specific implementation steps are as follows:

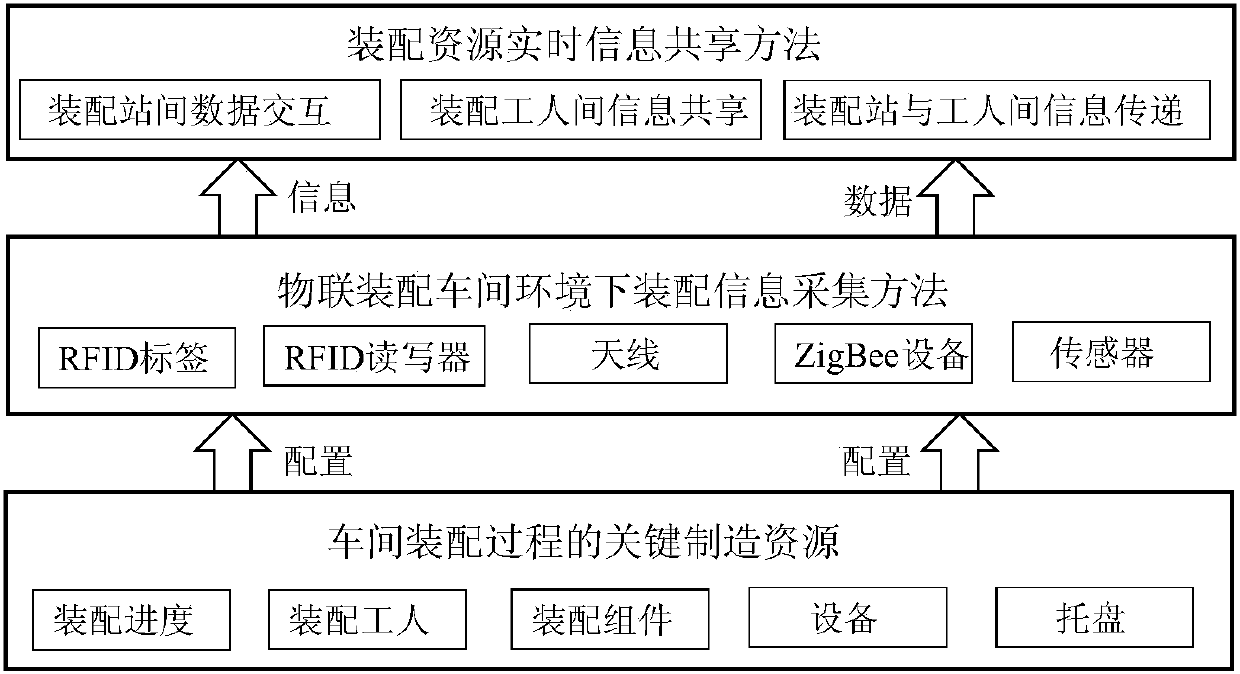

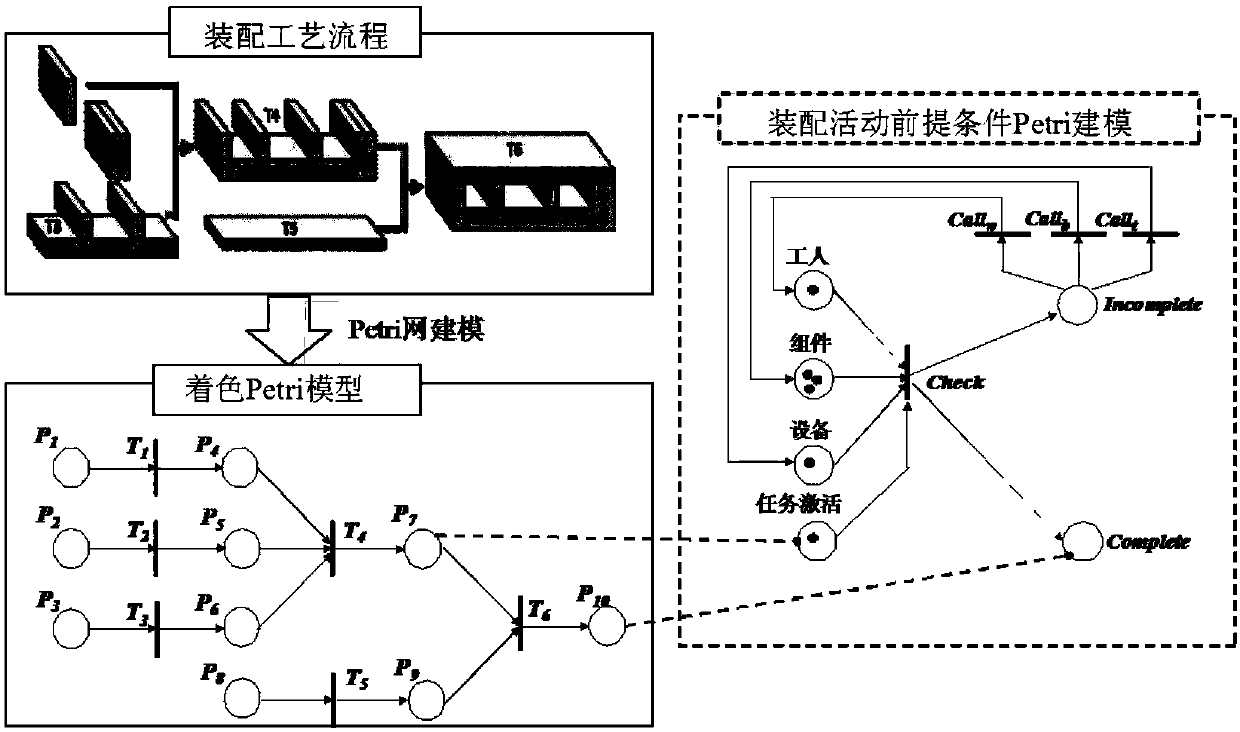

[0056] Step 1: Refer to figure 2 , based on the existing IoT sensing technology, build intelligent manufacturing resources that can perceive changes in its surrounding environment and its own oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com