A bonding reliability experiment device and control method for simulating lateral vibration conditions

A technology of lateral vibration and experimental equipment, which is applied in vibration testing, measuring equipment, testing of machine/structural components, etc., and can solve tensile tests that cannot achieve large displacements, large displacement stretching, and high-frequency vibrations Problems such as loading simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

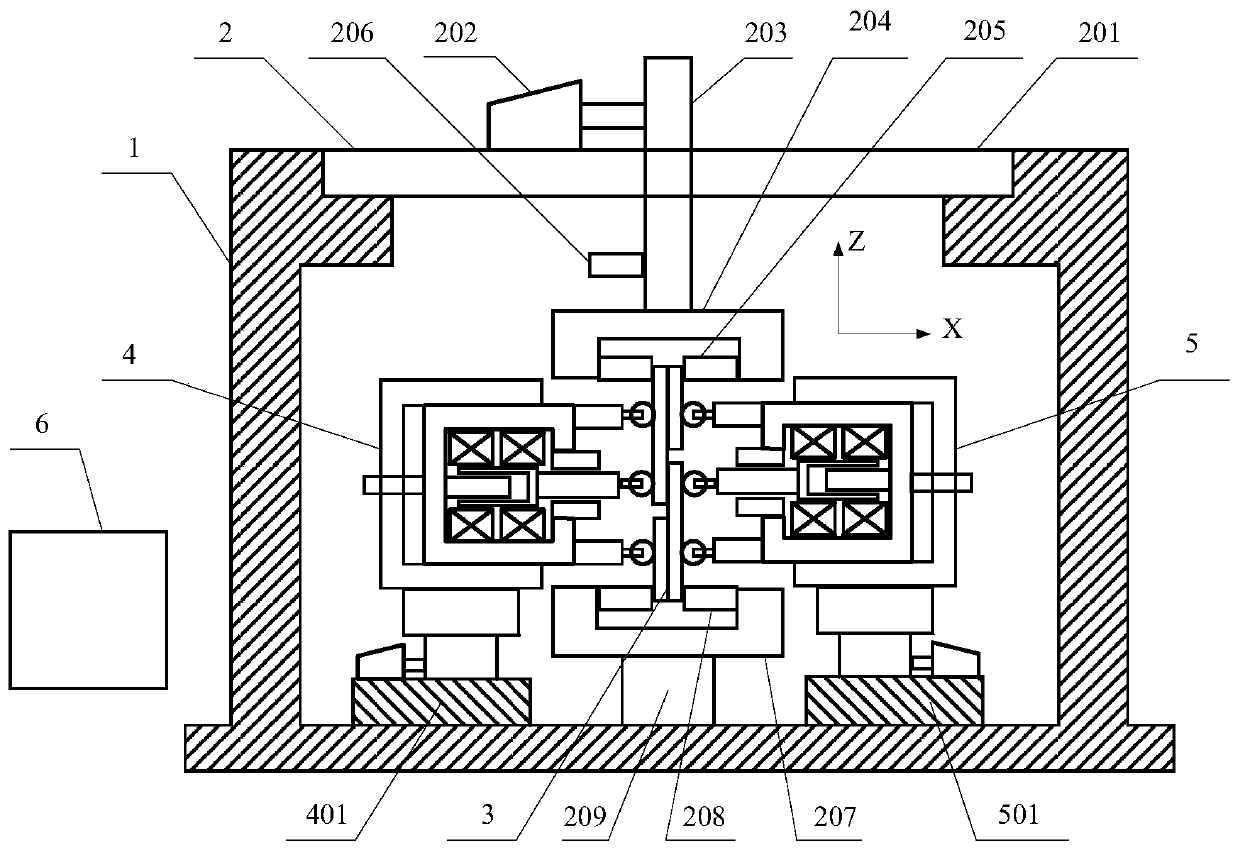

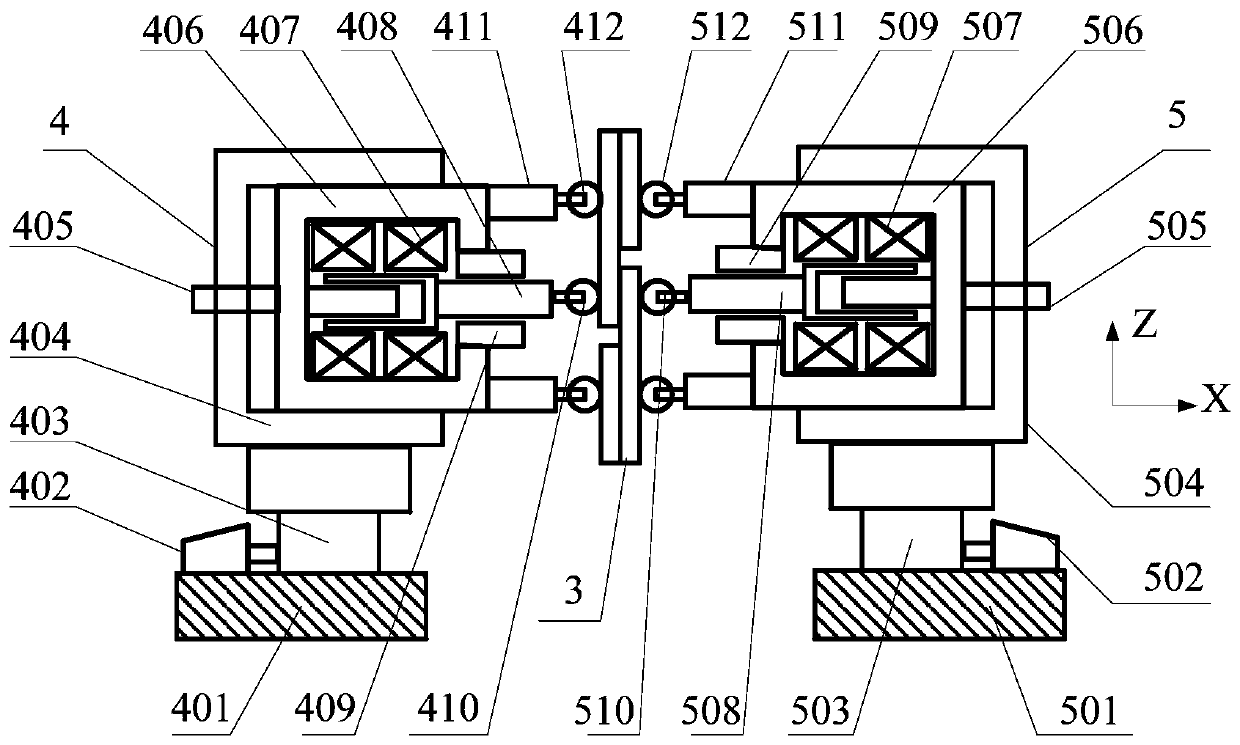

[0061] Such as figure 1 As shown, a bonding reliability experiment device that simulates lateral vibration conditions includes a frame body 1, a main loading platform 2, a bonding test sample 3, a left vibration loading platform 4, a right vibration loading platform 5, and a central control 器6 consists of. It is characterized in that: the frame body 1 mainly plays a role of stabilization and structural support, and it wraps other parts of the testing machine inside. Due to the force and vibration, it should be consolidated with the bottom surface during use. A main loading platform 2 is arranged on the upper part of the frame fuselage 1, wherein the main loading platform 2 includes a main loading platform base 201 arranged on the upper part of the frame fuselage 1, a main loading drive motor 202 located on the main loading platform base 201, and a main The main loading cantilever 203 connected to the loading drive motor 202, the upper chuck 204 connected to the end of the main l...

Embodiment 2

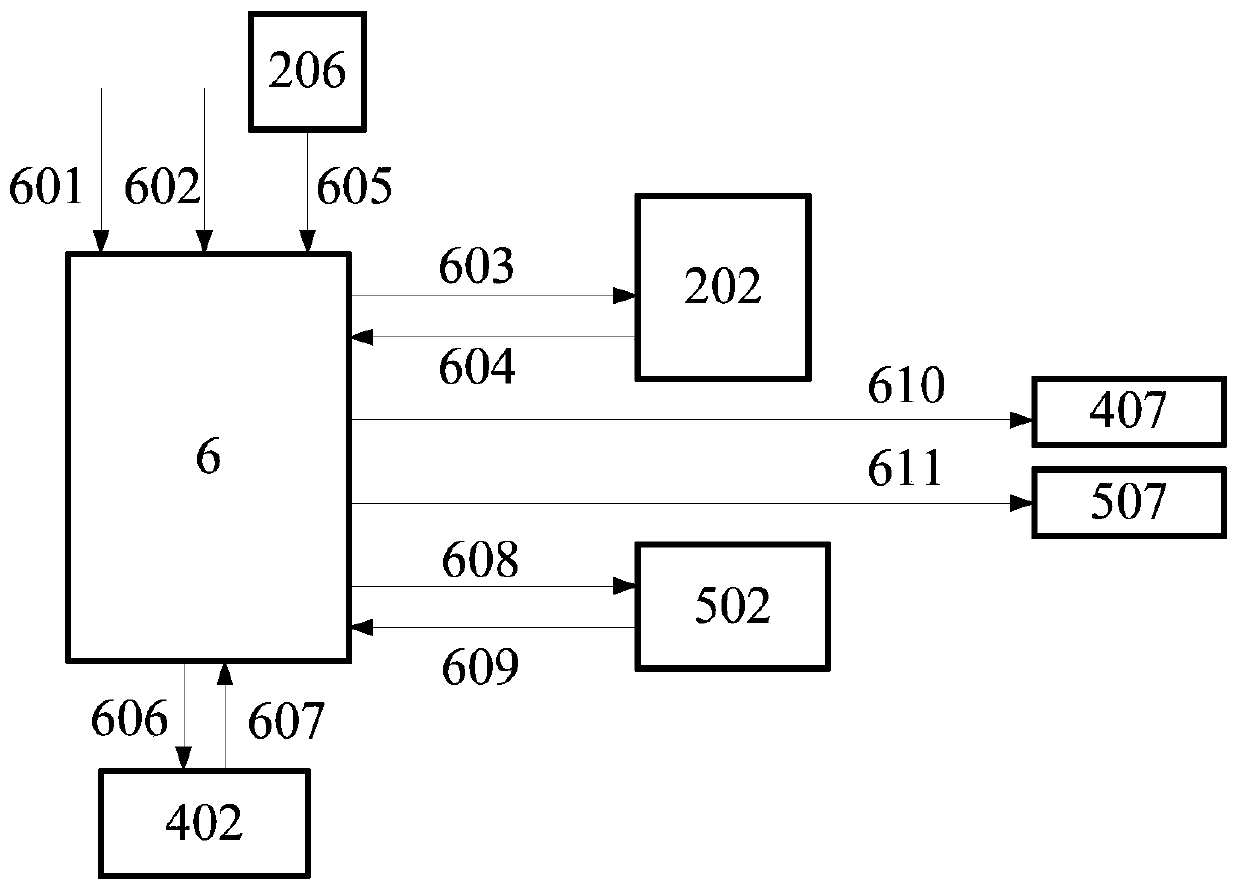

[0064] Such as image 3 As shown, a control method of a bonding reliability experimental device that simulates lateral vibration conditions is:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com