A kind of preparation method of paraffin section

A heather and leaf technology, which is applied in the field of dehydrating clearing agent, can solve the problems of complicated preparation method, complicated steps, long time-consuming and the like of paraffin slice preparation, and achieves the effects of short preparation period, simple operation and good tableting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This embodiment relates to a method for preparing paraffin sections of willow flower buds, comprising the following steps:

[0061] (1) Fixing: Fix the willow flower buds with FAA fixative solution for more than 24 hours, and peel off the scales of the fixed flower buds;

[0062] (2) Dehydration and transparency: the willow flower buds are first treated with 70% ethanol and 80% ethanol at a temperature of 24° C. and an absolute pressure of 0.02 MPa for 1 hour;

[0063] Then go through mixed solutions of distilled water, 95% ethanol and tert-butanol with different concentration gradients, and process at a temperature of 30°C and an absolute pressure of 0.02 to 0.03MPa, and each treatment time is 1h; Solution, by volume ratio, the volume ratio of distilled water, 95% ethanol solution and tert-butanol is 15:50:35; 5:40:55; 0:25:75, 0:0:100 and 0:0:100 (that is, the volume ratio of 0:0:100 needs to be performed twice); the willow flower buds are sequentially treated with t...

Embodiment 2

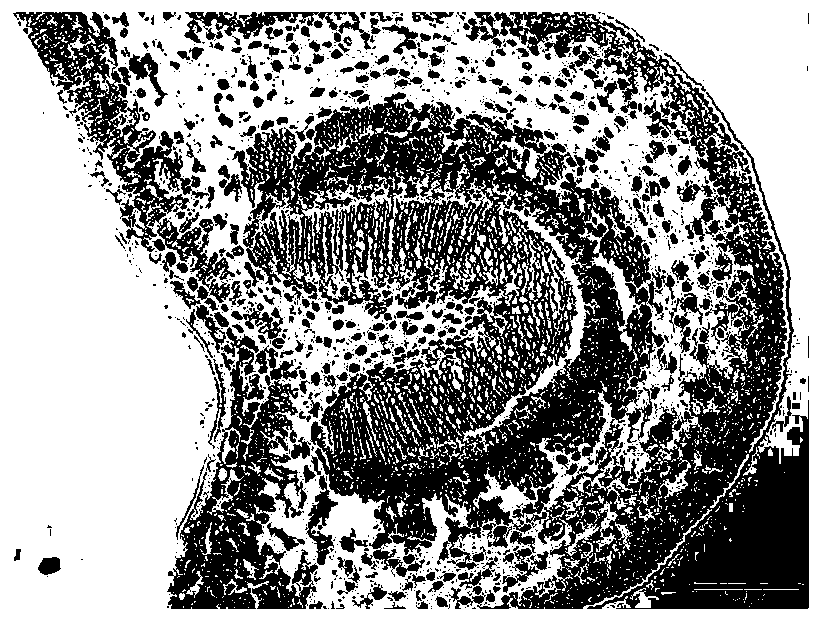

[0072] This example relates to a method for preparing paraffin sections of Photinia fragrans leaves, the steps of which are the same as those in Example 1. Its microstructure is shown in image 3 , as can be seen from the figure, its organizational structure is complete, there is almost no phenomenon of wax flakes falling off, and the image is clear.

Embodiment 3

[0074] This example relates to a method for preparing paraffin sections of young stems of Photinia fragrans, the steps of which are the same as those in Example 1. Its microstructure is shown in Figure 4 , as can be seen from the figure, its organizational structure is complete, there is almost no phenomenon of wax flakes falling off, and the image is clear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com