Drum-type sandstone aggregate drying and particle screening system

A kind of sand and gravel material and sub-system technology, which is applied in the direction of non-progressive dryers, dry solid materials, dry cargo handling, etc., can solve the problems of high construction period cost and labor cost, increased sampling and transportation costs, and lack of on-site rapid drying, etc. , to achieve the effect of increasing labor costs, reducing sample transportation and other procedures, and reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

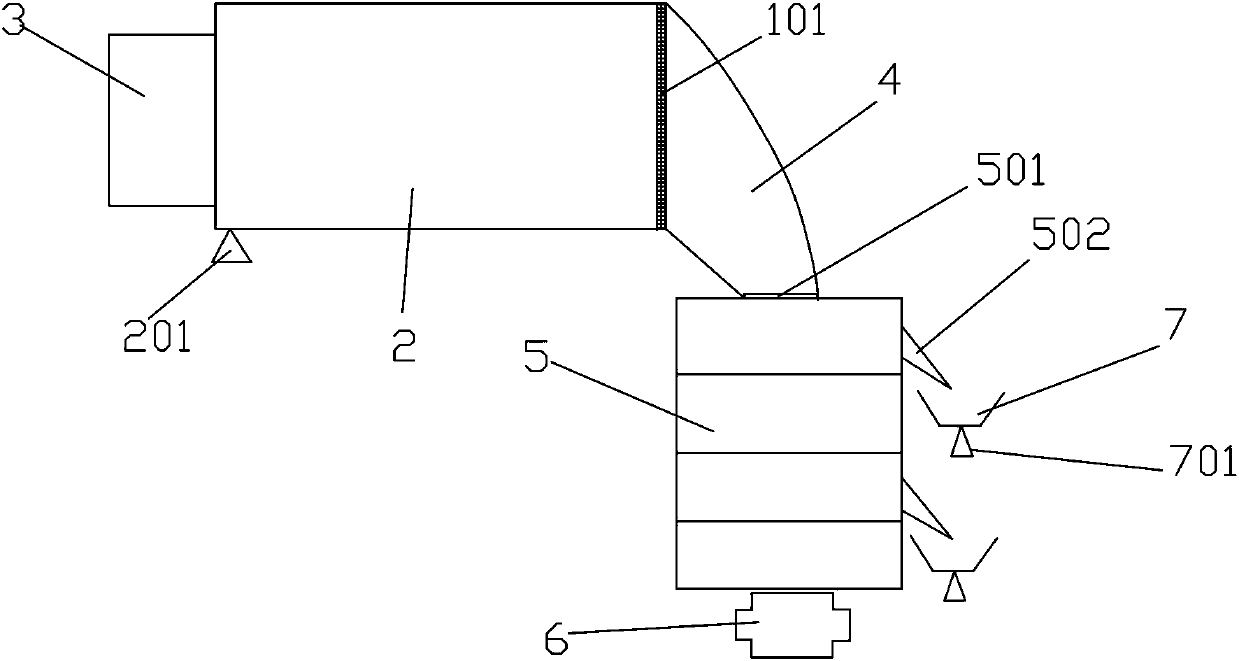

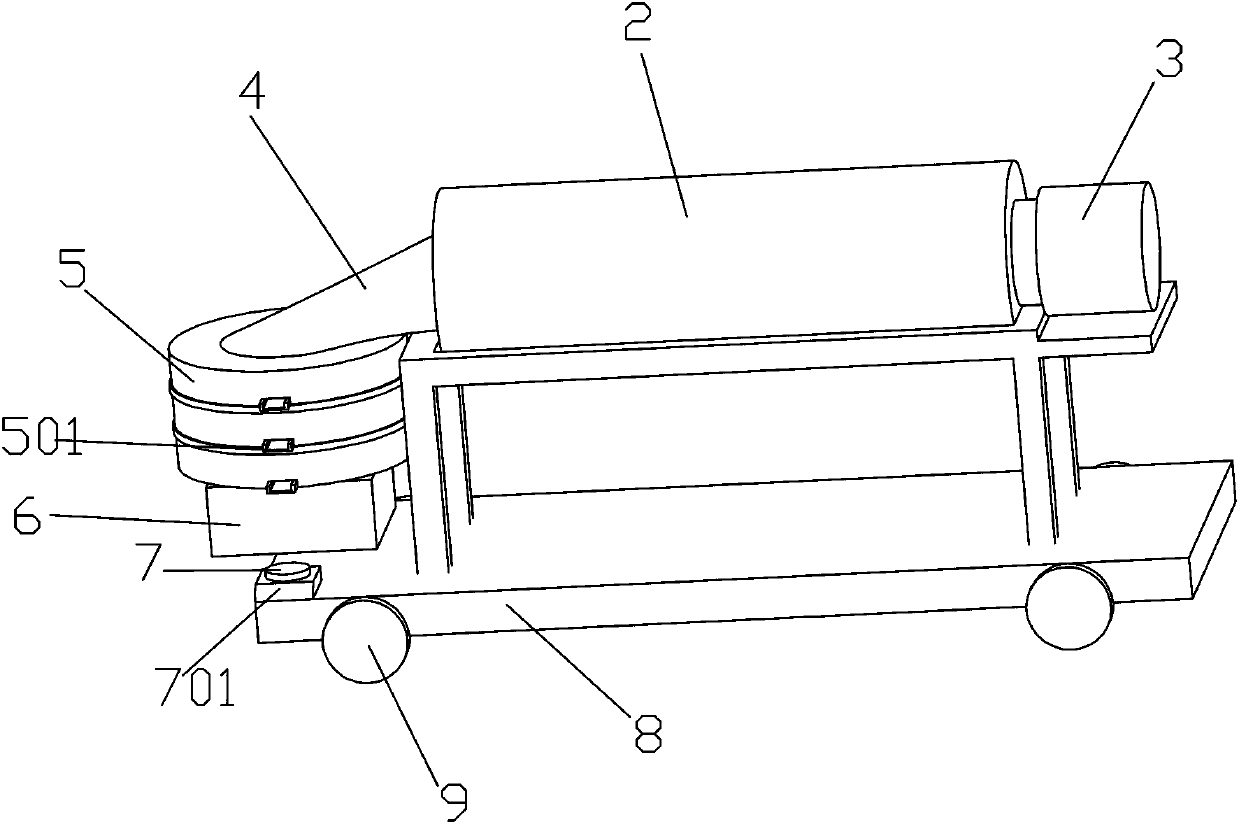

[0025] see Figure 1-3 .

[0026] The invention discloses a drum-type sand and gravel drying particle system, which includes a drying unit, a screening unit, and a quality collection unit. The drying unit includes a drum 1 arranged horizontally, a heating shell 2 arranged on the surface of the drum 1, and a The high-strength hot air blower 3 on one side of the drum 1, the drum 1 is driven to rotate by an external force; the screening unit includes a screen 5 arranged under one side of the drum 1, and a vibrating device 6 arranged at the bottom of the screen 5, A discharge port 501 is provided on one side of the screen; the mass acquisition system is provided below the discharge port 501 of the screen 5 .

[0027] The screens 5 include at least two and are arranged from top to bottom.

[0028] The screens 5 include three, and the mesh diameters of each screen 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com