High-glossiness and high-blackness spraying-free PC/PET alloy resin and preparation method thereof

A technology of alloy resin and high-speed mixer, which is applied in the field of polymer materials, can solve problems such as the inability to achieve spray-free effects, high blackness requirements, and insufficient gloss, and achieve good wear resistance, reduce spraying costs, and toughness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

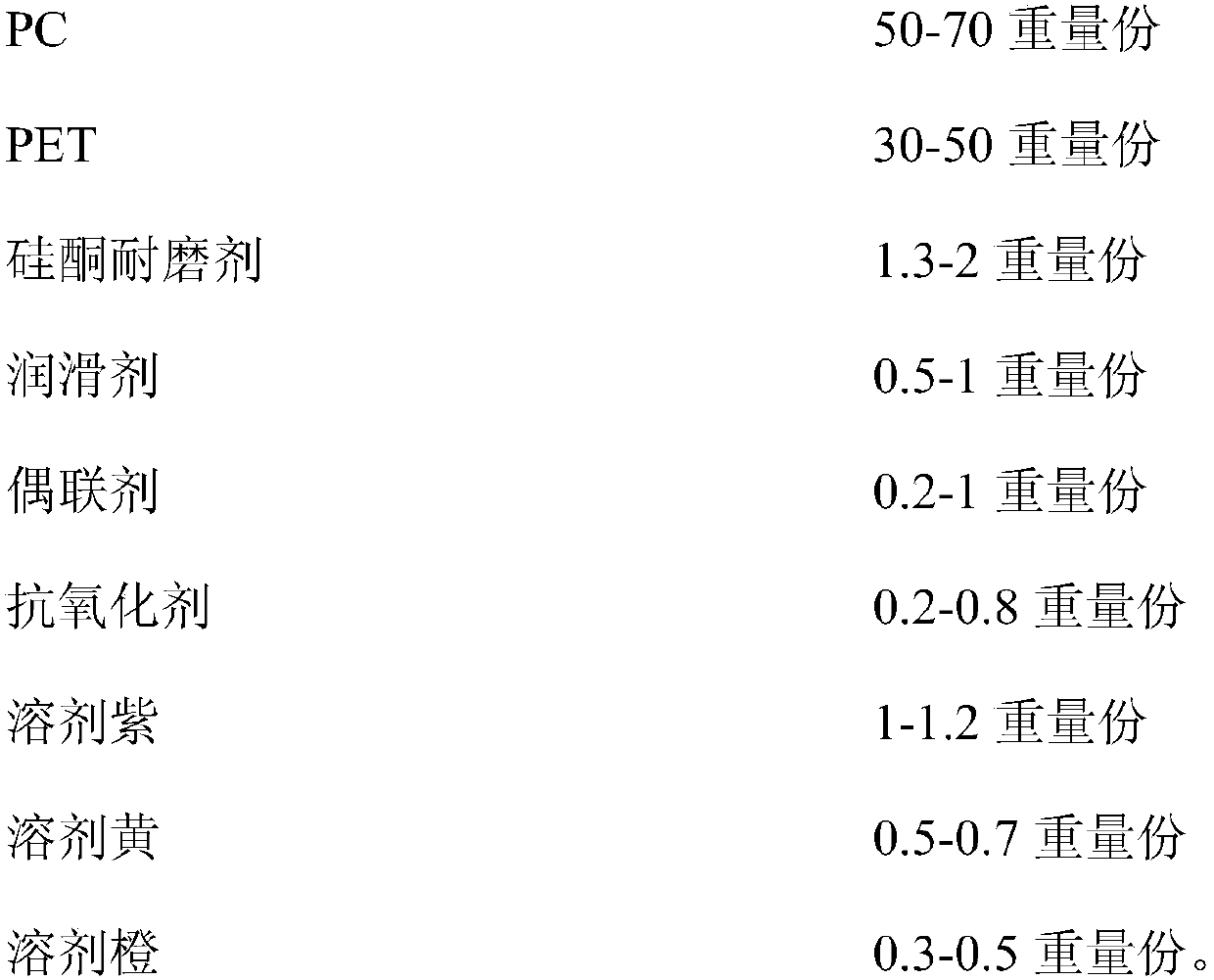

[0051] The raw materials for the preparation of the PC / PET alloy resin provided by this embodiment include the following components:

[0052]

[0053] The preparation method is as follows:

[0054] (1) Mix PC, PET, silicone anti-wear agent, lubricant, coupling agent and antioxidant in a high-speed mixer for 4 minutes.

[0055] (2) Add solvent violet, solvent yellow and solvent orange to the mixture obtained in step (1), mix in a high-speed mixer for 4.5 minutes, utilize a twin-screw extruder to melt for 2 minutes, extrude and pelletize to obtain the PC / PET alloy resin; the temperature of the twin-screw extruder is designed as follows: the temperature of the first zone is 230°C, the temperature of the second zone is 240°C, the temperature of the third zone is 250°C, the temperature of the fourth zone is 260°C, and the temperature of the fifth zone is 260°C. The temperature of the sixth zone is 260°C, the temperature of the seventh zone is 260°C, the temperature of the eight...

Embodiment 2

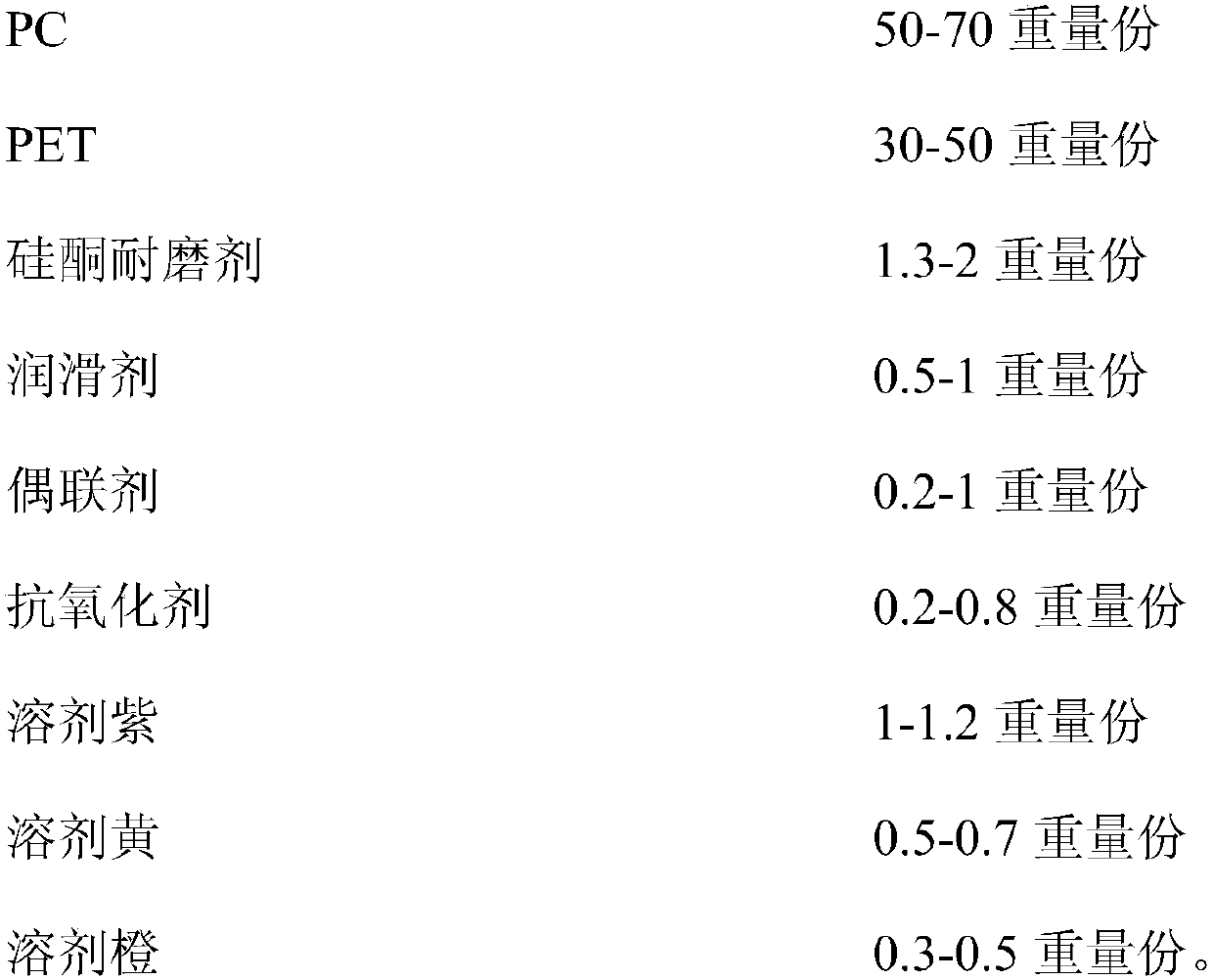

[0057] The raw materials for the preparation of the PC / PET alloy resin provided by this embodiment include the following components:

[0058]

[0059]

[0060] The preparation method is as follows:

[0061] (1) Mix PC, PET, silicone anti-wear agent, lubricant, coupling agent and antioxidant in a high-speed mixer for 3 minutes.

[0062] (2) Add solvent violet, solvent yellow and solvent orange to the mixture obtained in step (1), mix in a high-speed mixer for 5 minutes, melt with a twin-screw extruder for 1 minute, extrude and pelletize to obtain the PC / PET alloy resin; the temperature design of the twin-screw extruder is: the temperature of the first zone is 225°C, the temperature of the second zone is 235°C, the temperature of the third zone is 245°C, the temperature of the fourth zone is 255°C, the temperature of the fifth zone is 255°C, and the temperature of the sixth zone is 255°C. The temperature in the zone is 255°C, the temperature in the seventh zone is 255°C,...

Embodiment 3

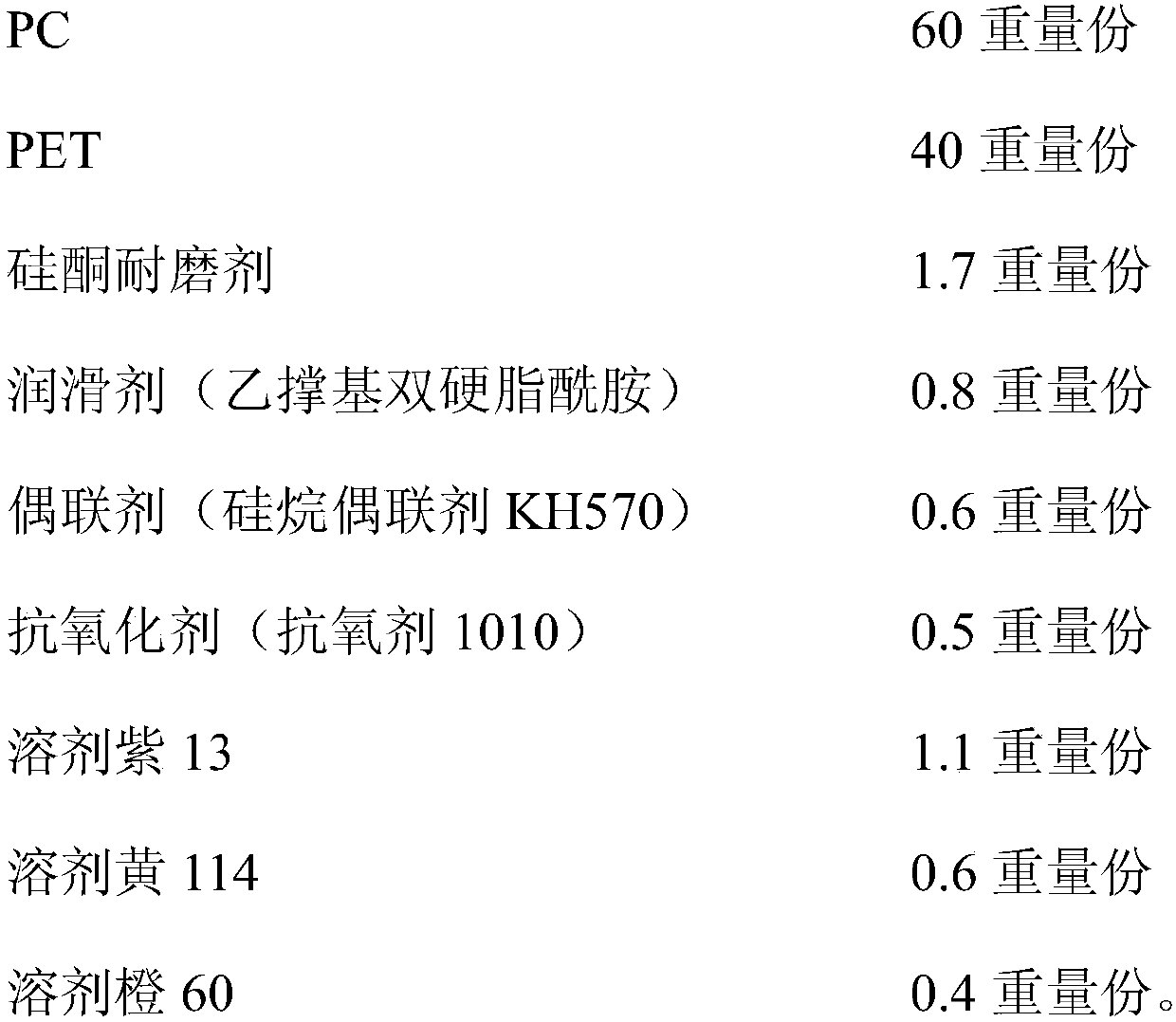

[0064] The raw materials for the preparation of the PC / PET alloy resin provided by this embodiment include the following components:

[0065]

[0066]

[0067] The preparation method is as follows:

[0068] (1) Mix PC, PET, silicone anti-wear agent, lubricant, coupling agent and antioxidant in a high-speed mixer for 5 minutes.

[0069] (2) Add solvent violet, solvent yellow and solvent orange to the mixture obtained in step (1), mix in a high-speed mixer for 4 minutes, utilize a twin-screw extruder to melt for 3 minutes, extrude and pelletize to obtain the PC / PET alloy resin; the temperature design of the twin-screw extruder is: the temperature of the first zone is 235°C, the temperature of the second zone is 245°C, the temperature of the third zone is 255°C, the temperature of the fourth zone is 265°C, the temperature of the fifth zone is 265°C, and the temperature of the sixth zone is 265°C. The temperature in the zone is 265°C, the temperature in the seventh zone is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com