Device and method for recycling grinding material from grinding material gas jet

A technology of gas jet and recovery device, which is applied to the feeding device of abrasive materials, the processing device of used abrasive materials, abrasive materials, etc., which can solve the problem of poor open-air discharge of erosion waste, difficulty in screening and reuse, and difficulty in mixing waste materials And other problems, to achieve the effect of repeated use, improve the utilization rate of abrasives, and reasonable steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

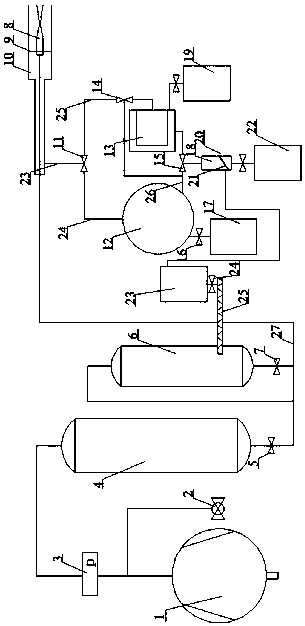

[0030] An abrasive gas jet abrasive recovery device, such as figure 1 Shown, comprise air compressor 1, gas cylinder 4, storage tank 6, nozzle 8, abrasive material recovery cover 10, magnetic force separator 12, gravity separator 13 and particle size separator 20, magnetic force separator 12 , gravity separator 13 and particle size separator 20 are prior art, not shown in the figure.

[0031] The air outlet of the air compressor 1 is connected to the air inlet of the gas cylinder 4; a pressure gauge 3 and an unloading valve 2 are connected between the air outlet of the air compressor 1 and the air inlet of the air cylinder 4 to ensure that the device is in operation. safety.

[0032] The top and the bottom of the storage tank 6 are respectively provided with an upper air inlet and a lower air inlet, and the bottom of the storage tank 6 is also provided with a discharge port, and the discharge port of the storage tank 6 is provided with a discharge valve 7 , so as to realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com