Turning-milling complex eccentric cutter handle

A tool holder and eccentric technology, which is applied in the field of turning-milling compound eccentric tool holder, can solve the problems of affecting product accuracy, easy to produce errors, small tool holder design, etc., and achieve the effect of simple design structure, strong functionality and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

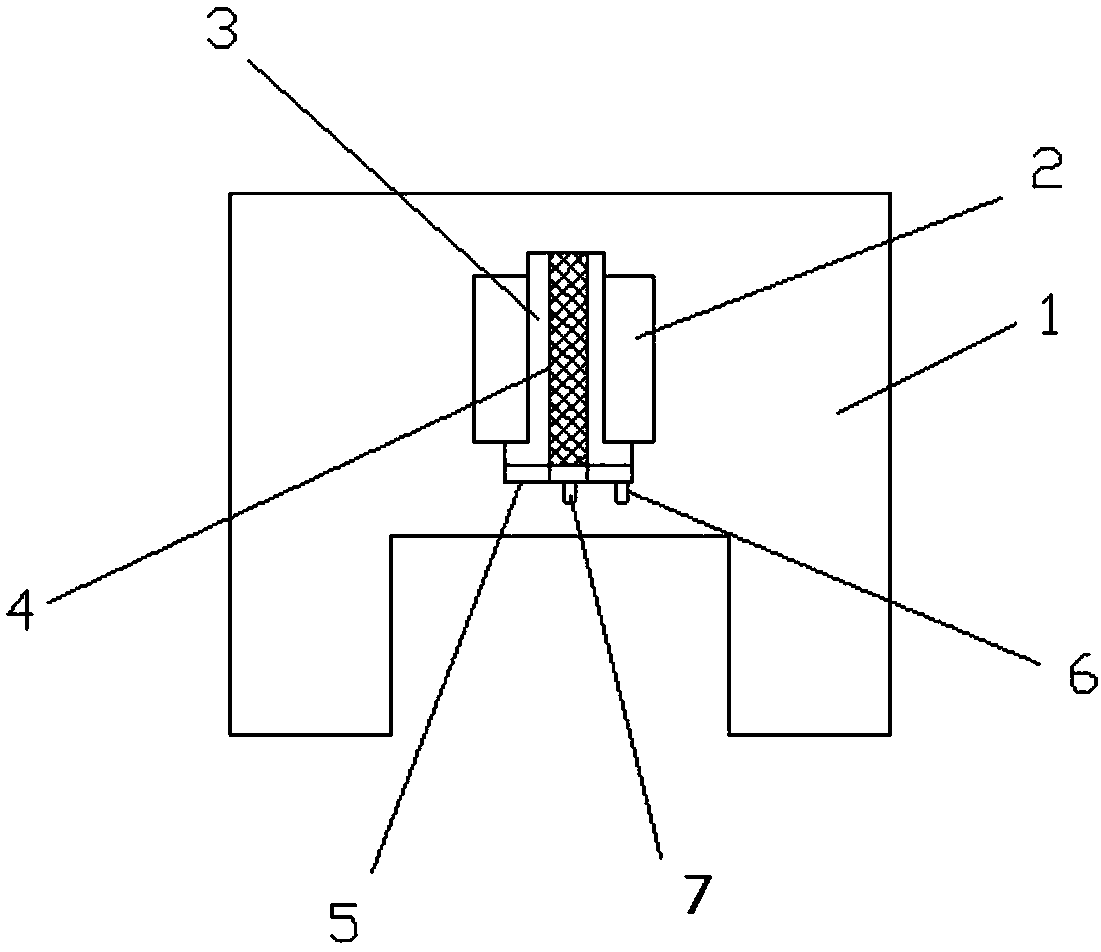

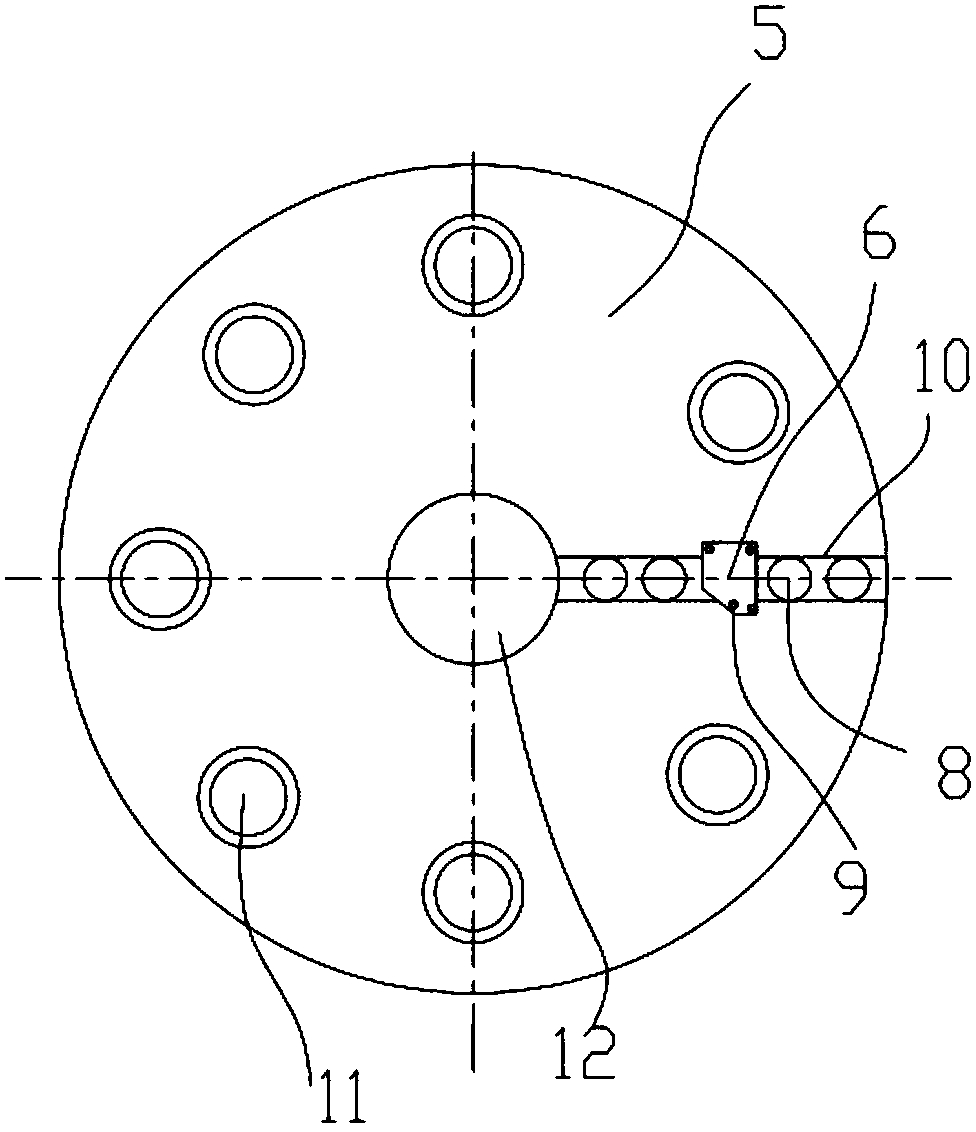

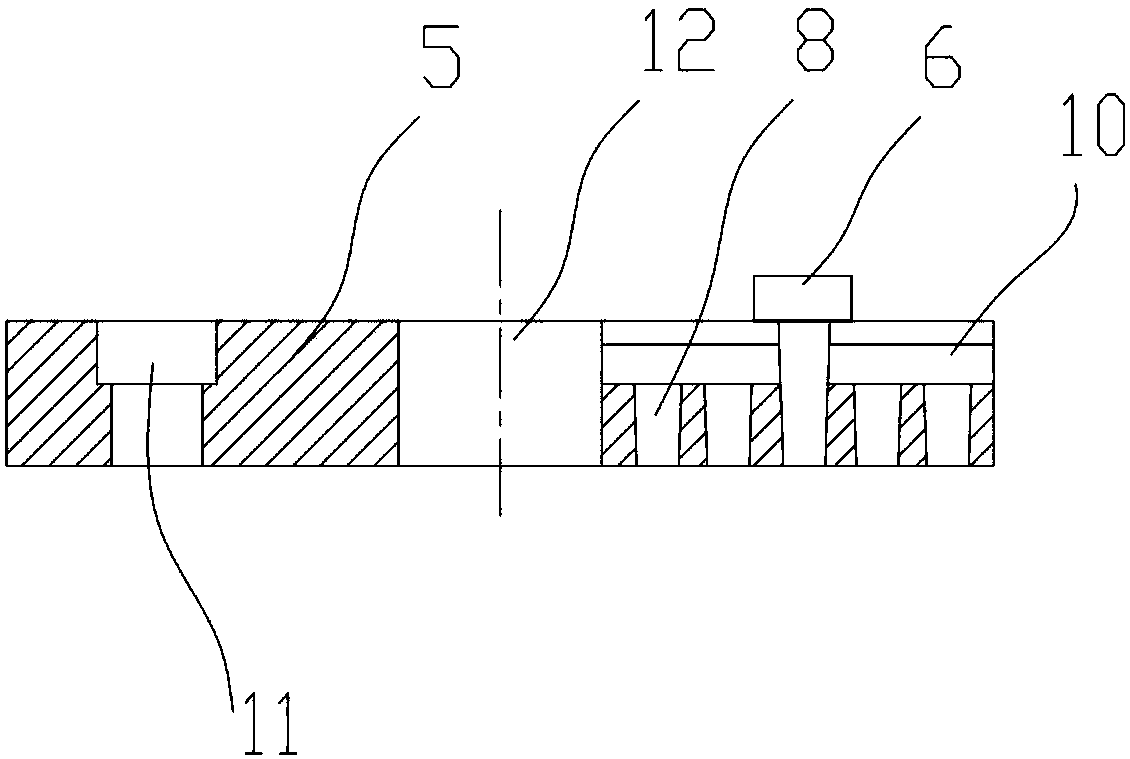

[0022] see Figure 1-3 As shown, the present invention provides a technical solution: a turning-milling compound eccentric tool holder 5, including a machine bed 1, a spindle box 2, a spindle 3, a spindle axis 4, a tool handle 5 and a tool 6, and a machine bed 1 The interior of the spindle box 2 is provided with the spindle box 2, the center of the spindle box 2 is provided with the spindle axis 4, the outer surface of the spindle axis 4 is provided with the spindle 3, the bottom of the spindle 3 is fixedly connected to the tool handle 5, and the center of the tool handle 5 is positioned A cutter 6 is eccentrically connected to the outer side of the spindle axis 4 and the center of the bottom of the handle 5 .

[0023] The tool hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com