Special CNC (computer numerical control) machine tool for tappet drilling

A CNC machine tool and bed body technology, applied in the field of machine tools, can solve the problems of difficulty in guaranteeing the error angle of the drilling mold, poor guarantee of the dimension angle, and the drill bit breaking on the workpiece, etc., so as to achieve scientific and simple machine tool structure design and good inner hole tolerance , to ensure the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

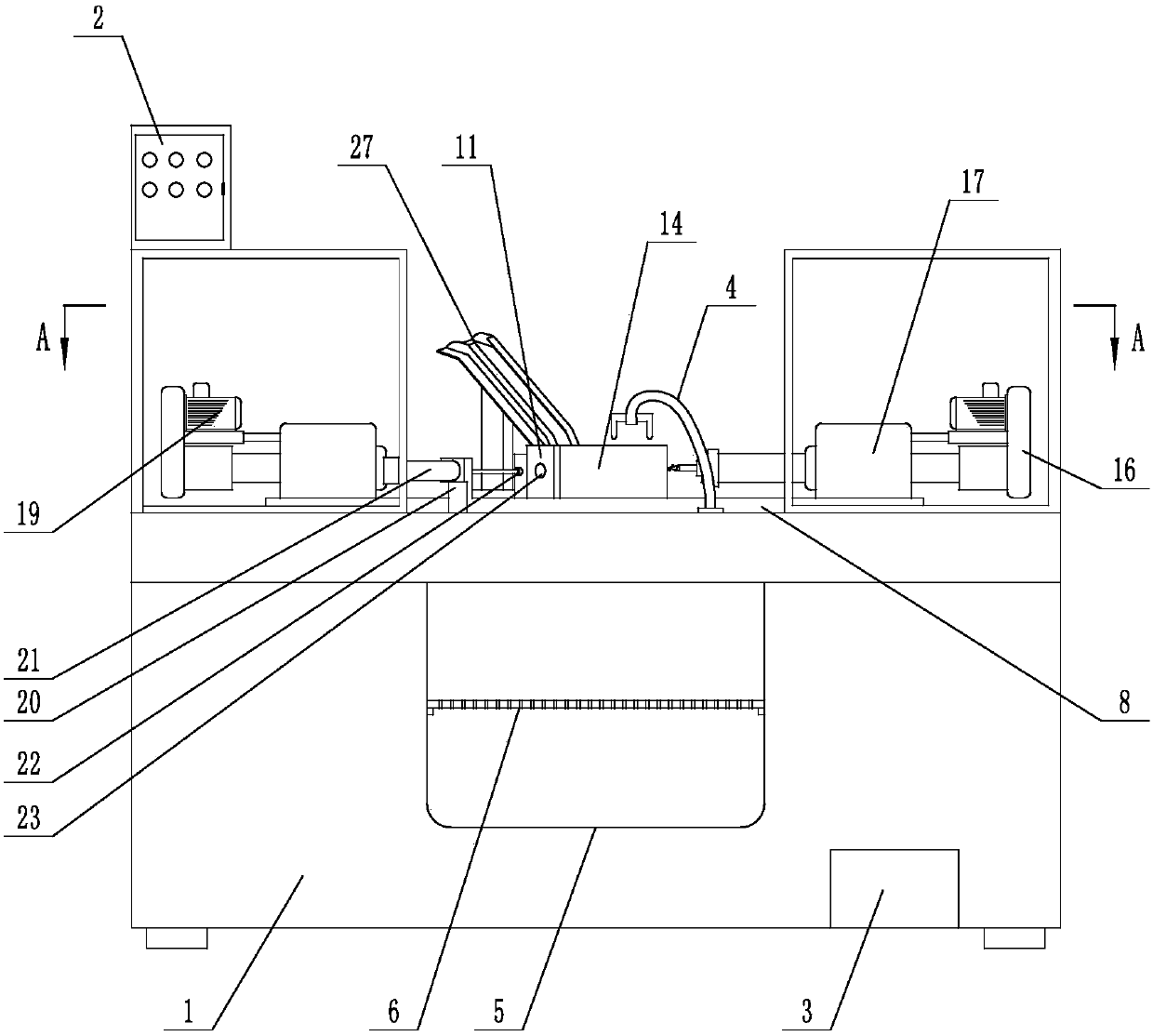

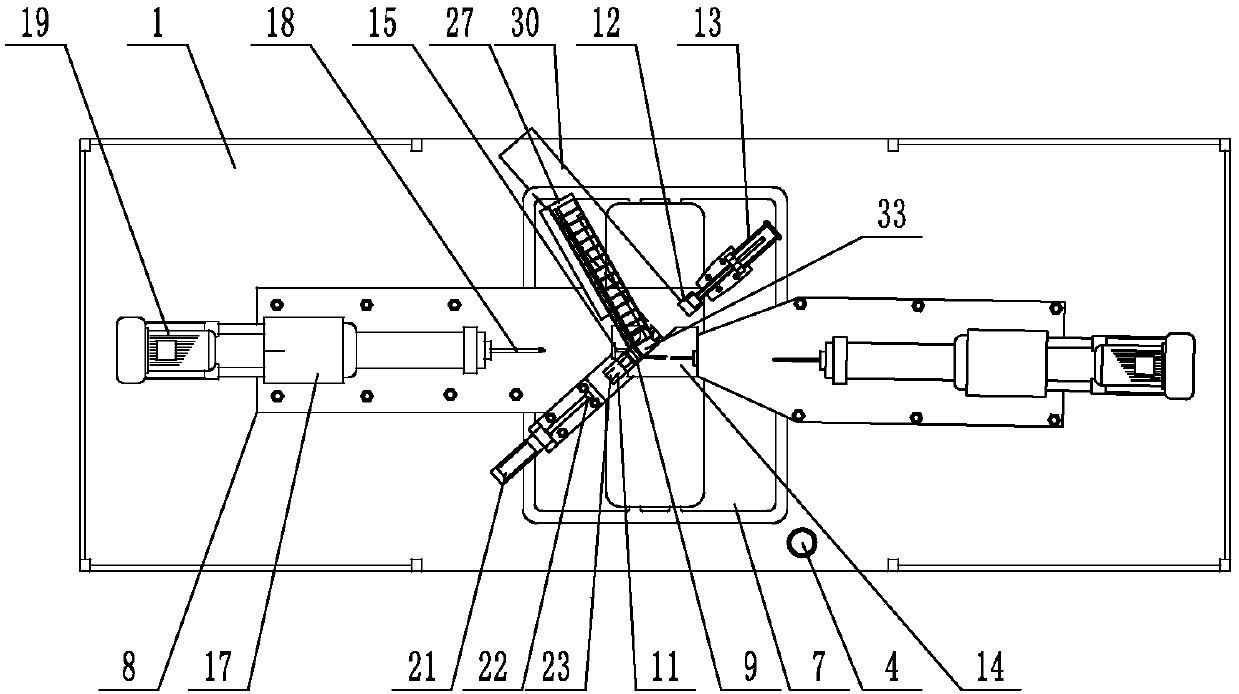

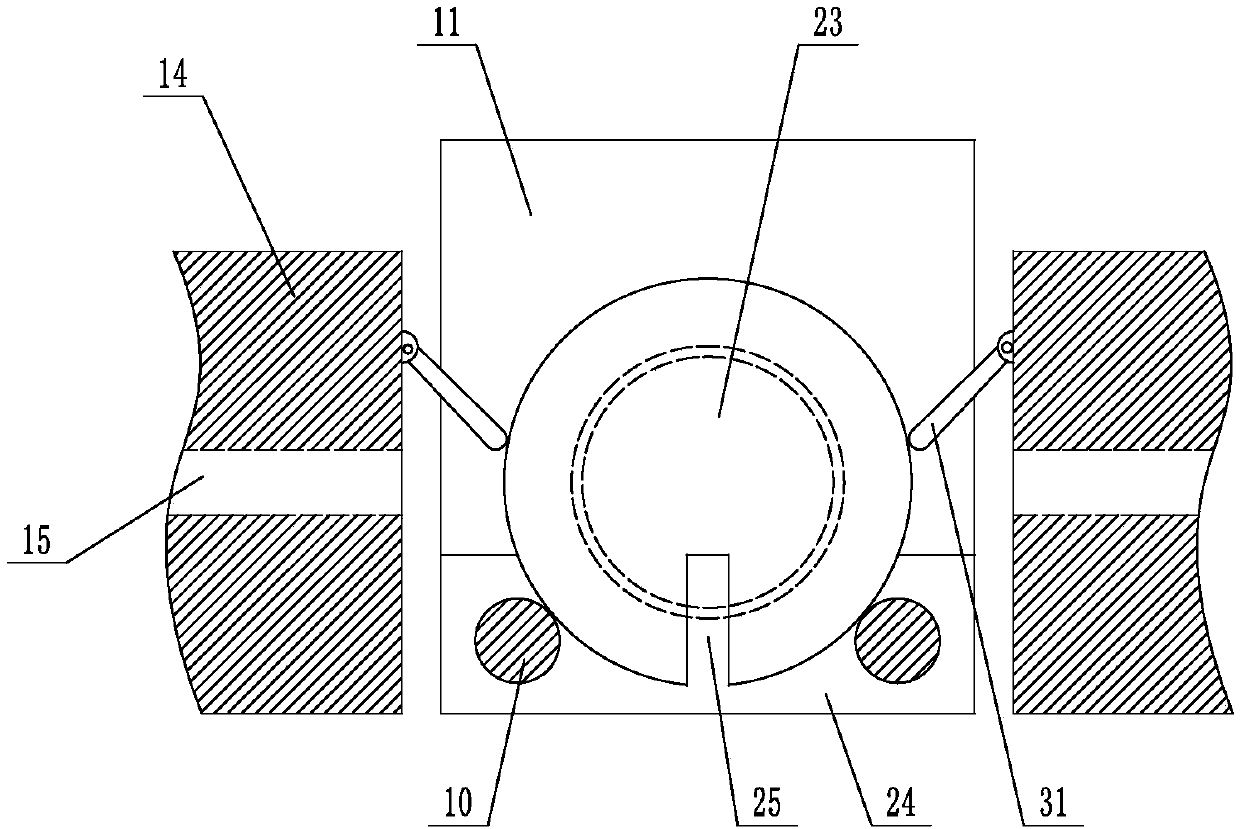

[0028] Such as Figure 1-9 As shown, the present invention includes a bed body 1, a control box 2, an oil pump 3 and an oil return device 4 inside the bed body 1, an oil return tank 5 inside the bed body 1 and a filter residue plate 6 located in the middle of the oil return tank 5. A rectangular opening 7 is arranged in the middle of the table top of the bed body 1, and the lower side of the rectangular opening 7 is a filter residue plate 6. The upper end of the bed body 1 is fixedly connected with a base 8, and a workpiece 33 groove 9 is arranged in the middle of the base 8, and the workpiece 33 The lower end of the groove 9 is provided with a plurality of transverse support columns 10 supporting the workpiece 33, and both sides and the middle of the support columns 10 are hollowed out. Iron filings and oil return drilled during workpiece 33 fall into the oil return tank 5 through the hollow and rectangular opening 7, and are recycled by filtering through the filter residue p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com