Ultrasonic-table-floatation combined desliming process

An ultrasonic and desliming technology, which is applied in the field of ultrasonic-shaking table-flotation combined desliming process, can solve the problems of not achieving the desliming effect, increasing foam viscosity, and deteriorating flotation index, etc., so as to reduce the subsequent operation load , prevent fine mud agglomeration, reduce the effect of desliming cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

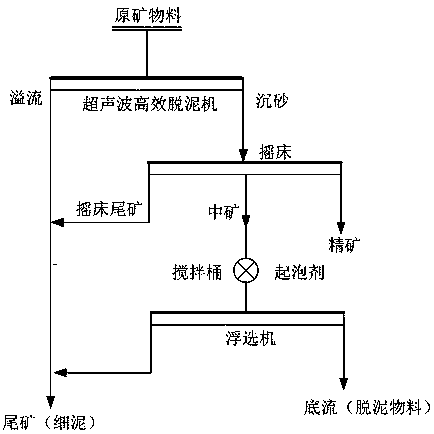

[0019] Embodiment 1: Ultrasonic-shaking table-flotation combined desliming process, the specific operation is as follows:

[0020] The original slime of a weathered iron ore in Sichuan has a mud content of 30%. After two times of desliming of the iron concentrate after magnetic separation using a traditional cyclone, the mud content is still above 5%. The obtained iron concentrate The grade is 61.63%.

[0021] Adopt the inventive method, technological process such as figure 1 As shown, the iron concentrate after magnetic separation is subjected to ultrasonic-shaking table-flotation combined desliming. First, the iron concentrate after magnetic separation with a concentration of 10% is removed by an ultrasonic deslimer. The overflow of the mud machine is directly thrown to the tail, and the sand settling of the ultrasonic desilter is separated and deslimed by a shaking table. The shaker concentrate is used as a qualified material after desliming. Foaming agent 2 # Oil 75g / t,...

Embodiment 2

[0024] Embodiment 2: ultrasonic-shaking table-flotation combined desliming process, the specific operation is as follows:

[0025] A lead-zinc oxide mine in Guangxi has a mud content of 25%. The mud content is still greater than 10% by pre-selection and desliming in a deslimer. Then, the sulfide-amine method is used for flotation, which consumes a lot of reagents. Finally, in the concentrate, Pb The grade is 31.50%, the recovery rate is 56%, the Zn grade is 25.65%, the recovery rate is 63.7%, the flotation index is poor, and the foam is sticky and the groove is serious.

[0026] Adopt ultrasonic wave-shaking table-flotation combined desliming process described in the present invention, technological process is as follows figure 1 As shown, the raw ore of a lead-zinc oxide mine in Guangxi was deslimed in advance. First, the raw ore with a concentration of 40% was removed by an ultrasonic deslimer. The overflow of the ultrasonic deslimer was directly thrown at the tail, and the ...

Embodiment 3

[0028] Embodiment 3: Ultrasonic-shaking table-flotation combined desliming process, the specific operations are as follows:

[0029] The mud content of a weathered titanium ore in Yunnan is 21%, and the mud content is still greater than 6% through cyclone pre-selection. After desliming, the hydroxamic acid collector is used for flotation to obtain the Ti grade in the titanium concentrate. 33.70%, recovery rate 66.83%.

[0030] Adopt ultrasonic wave-shaking table-flotation combined desliming process described in the present invention, technological process is as follows figure 1 As shown, the raw ore of a lead-zinc oxide mine in Guangxi is deslimed in advance. First, the raw ore with a concentration of 25% is removed through an ultrasonic deslimer to remove part of the slime. The sand settling of the machine adopts the shaking table for sorting and desliming. The shaker concentrate is used as the qualified material after desliming. The tailings of the shaking table are directl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com