SCR flue gas denitration control method for coal-fired unit based on neural network predictive control

A technology of predictive control and coal-fired units, which is applied in the field of flue gas denitrification, can solve the problems of inability to accurately control the amount of ammonia injection in the SCR out-of-stock system, difficulty in ensuring NOx emission standards, and increase of ammonia escape, etc., to achieve easy online calculation and overcome waste reduction The effect of low requirements on agent and model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

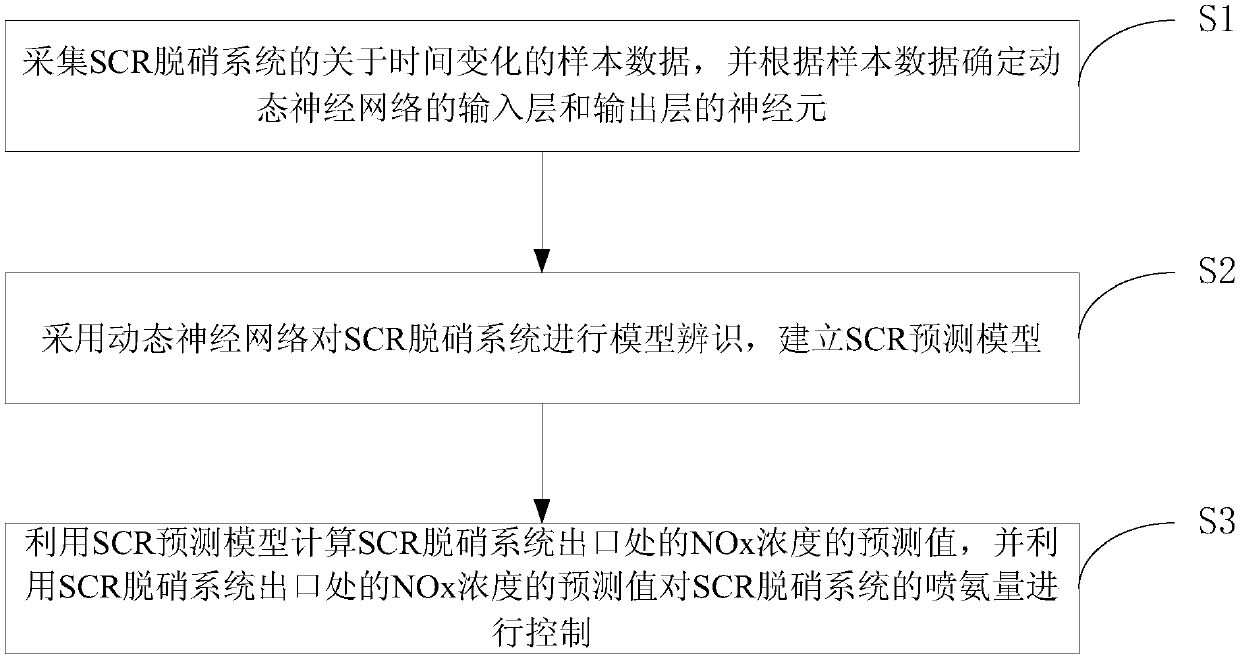

[0036] Include the following steps:

[0037] Step S1, collect sample data about time changes of the SCR denitrification system, and determine the neurons of the input layer and output layer of the dynamic neural network according to the sample data;

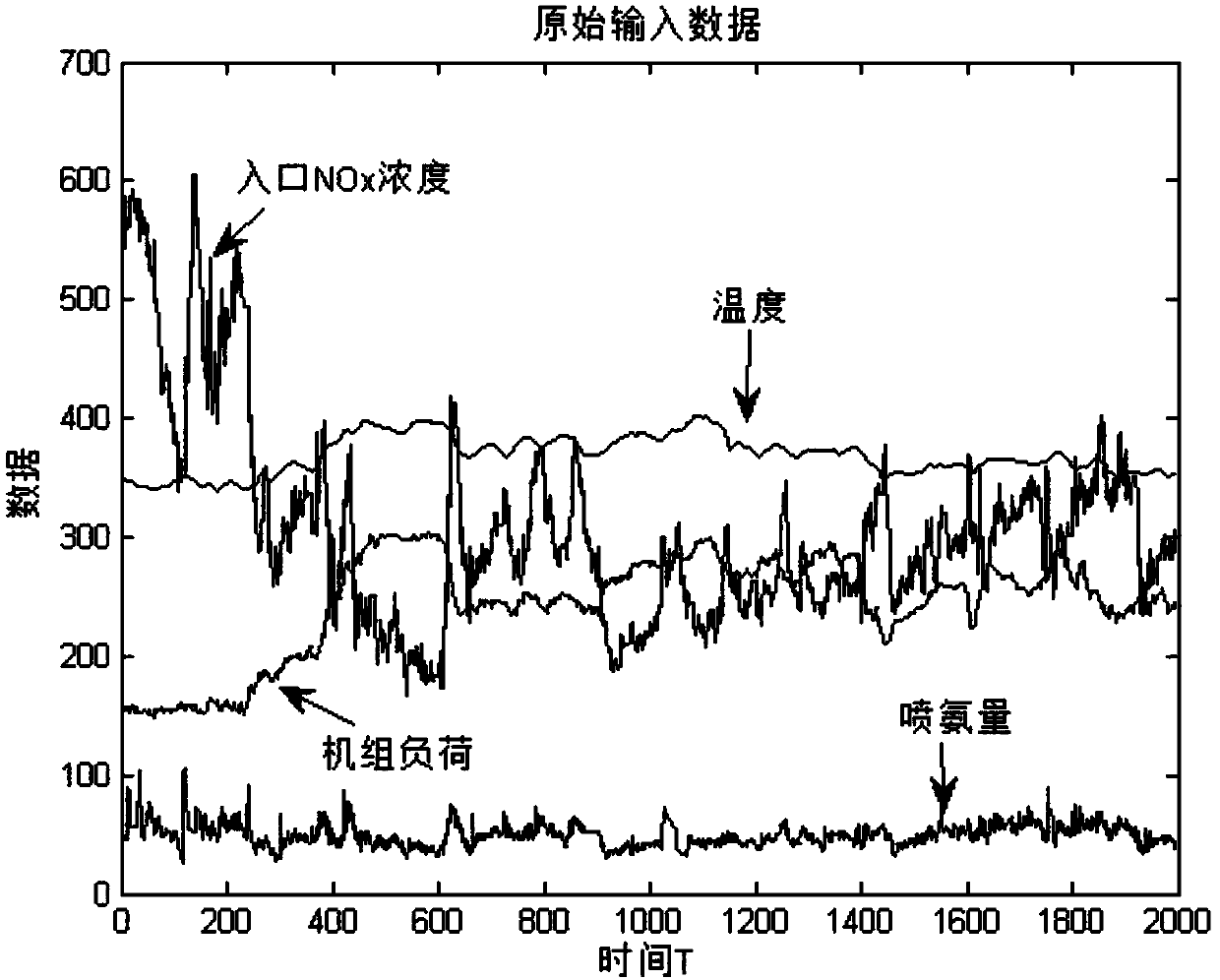

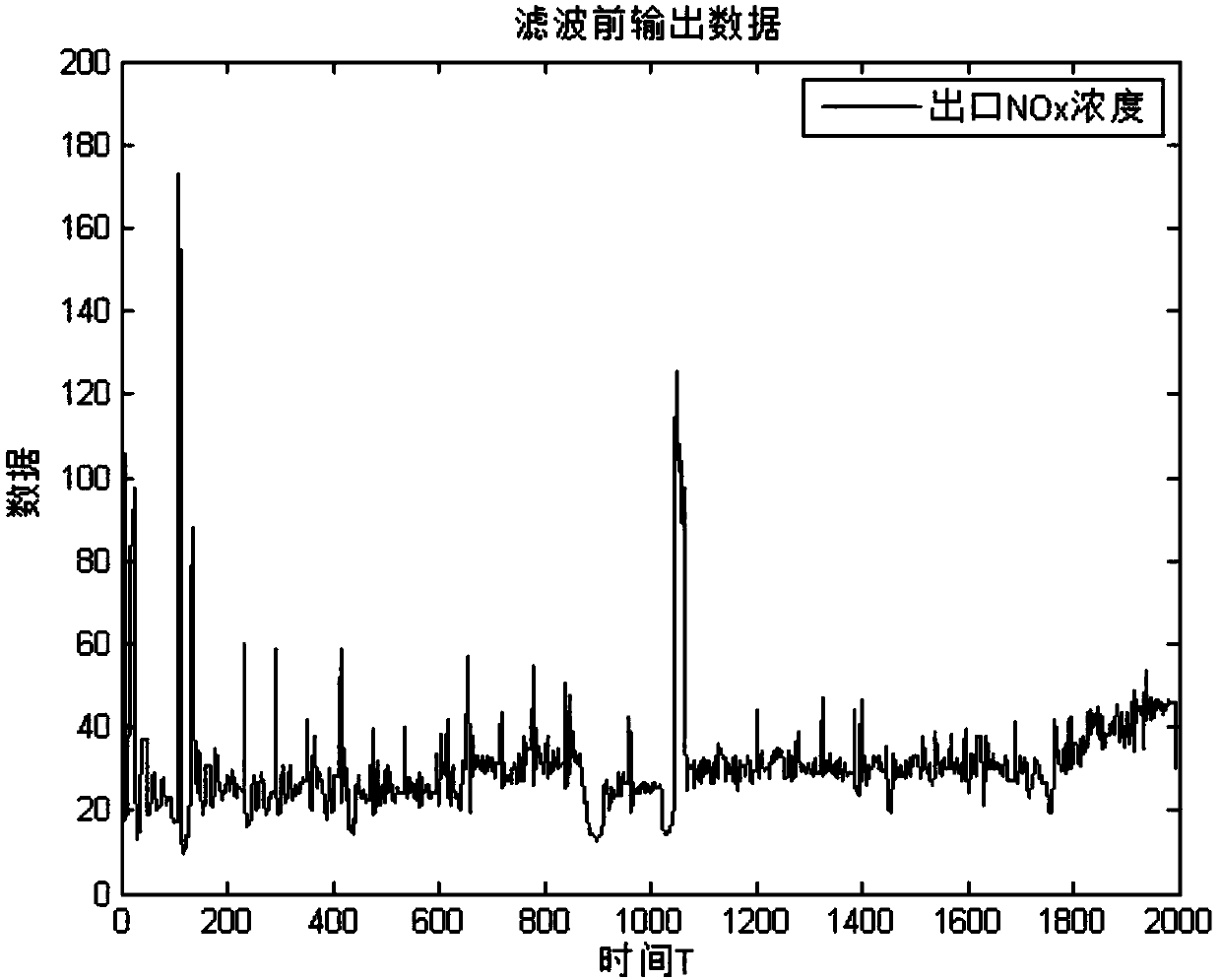

[0038] In this embodiment, in order to provide the model network with input and output data pairs that comprehensively and correctly reflect system characteristics, the data collected and put into network training should satisfy the following three characteristics: ergodicity, compactness and compatibility. That is, the learning samples cover all possible state space conditions of the object as much as possible; and the learning sample density within a certain space range must be appropriate, so that the characteristics of the object can be collected. The number of samples required for training the network depends on the complexity of the research object and the influence of noise on the experimental object, that is, the system c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com