Spark catcher

A spark trap and shell technology, applied in the field of spark traps, can solve the problems of unscientific use of waste heat, waste of energy, pollution of smoke and dust, etc., and achieve the effects of simple and reliable operation, low investment, and elimination of smoke and dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

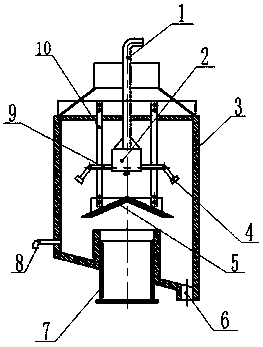

[0012] Examples, see attached figure 1 , a kind of spark arrester, including water pipe 1, water distribution tank 2, housing 3, nozzle 4, top cover 5, drain pipe 6, chimney 7, overflow pipe 8, water distribution pipe 9 and mounting bracket 10, its features That is, the bottom surface of the housing 3 is an inclined plane and the left side is high and the right is low, the central hole at the bottom end of the housing 3 is fixedly installed on the chimney 7, and the drain pipe 6 is installed on the right side of the bottom surface of the housing 3, and the housing 3 An overflow pipe 8 is installed on the left side near the bottom, and the top surface of the casing of the water pipe 1 is connected to the upper interface of the water distribution tank 2 through the inner hole, and the water distribution pipe 9 is installed on the lower side wall of the water distribution tank 2, so that The nozzle 4 is installed at the end of the water distribution pipe 9 , the installation brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com