Water tank type destroying device for initiating explosive devices

A technology for destroying devices and pyrotechnics, which is applied in blasting, separation of dispersed particles, chemical instruments and methods, etc., and can solve problems such as great health hazards and affecting operator efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

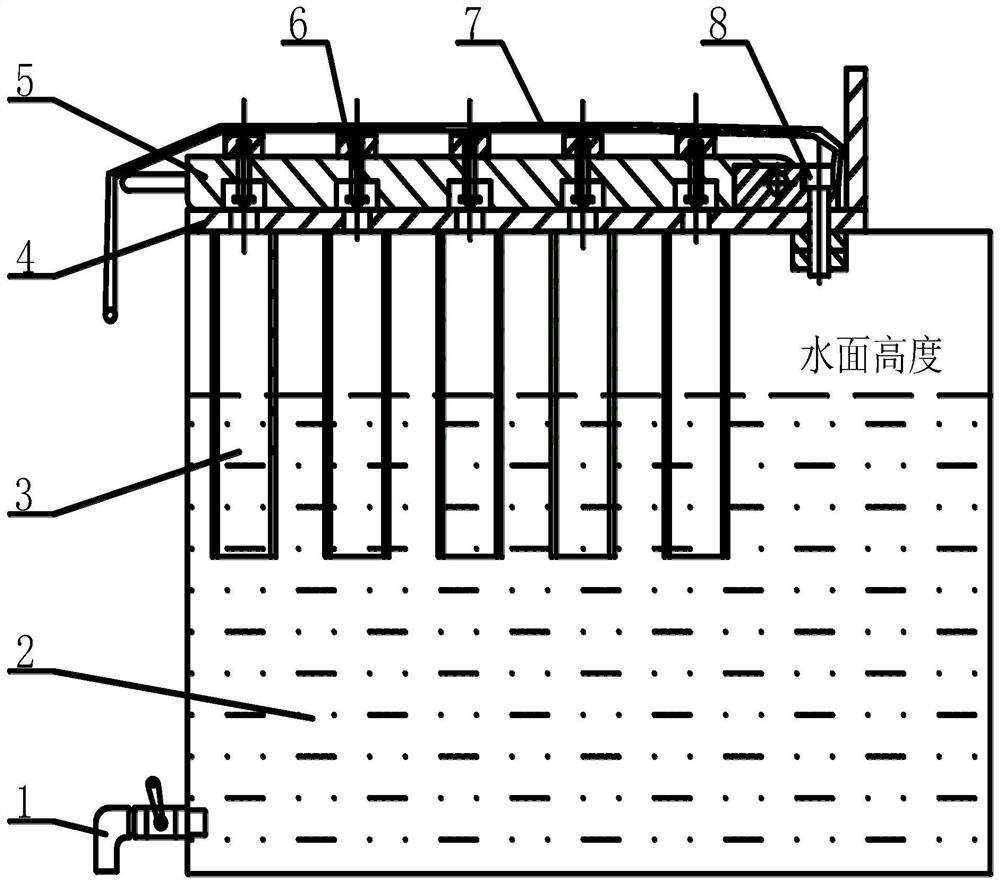

[0013] The pyrotechnic water tank type destruction device involved in this embodiment has a structure such as figure 1 As shown, the device is composed of a water valve 1, a sleeve 3, a positioning plate 4, a cover plate 5, a firing mechanism 6, a waterproof cloth 7, and a fixing bolt 8; the sleeve 3 is accurately welded to each positioning hole on the positioning plate 4 After the firing mechanism 6 and the cover plate 5 are accurately assembled, the cover plate 5 is installed on the positioning plate 4 with the fixing bolts 8, and finally the positioning plate 3 is welded on the water tank 3, and the waterproof cloth 7 is spread on the surface of the firing mechanism 6. Water valve 1 is arranged at the bottom of the water tank.

[0014] Before use, inject tap water into the water tank 2. Before use, inject water into the water tank 2 until the water level submerges one-half of the sleeve 3, and then fire the pyrotechnic device to destroy the dust and smoke generated when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com