Filled noodle making machine

A noodle machine and sandwich technology, applied in dough extruders, dough forming machinery or equipment, baking, etc., can solve problems such as inconvenient use, complex structure, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

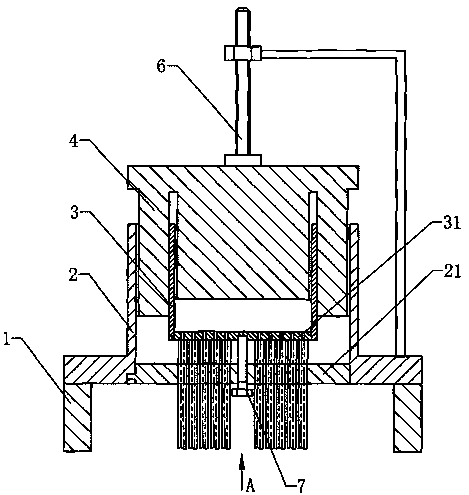

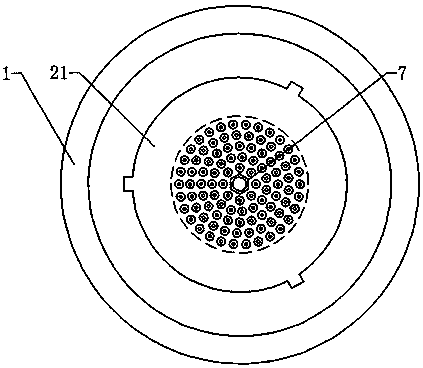

[0014] Such as figure 1 As shown, the sandwich noodle machine includes a frame 1, a noodle bowl 2 mounted on the frame 1, and a noodle bowl 2 is fitted with a filling cylinder 3, and the noodle bowl 2 and the filling cylinder 3 are installed concentrically , There are pistons 4 in the noodle-containing cylinder 2 and the filling-containing cylinder 3. Since the noodle-containing cylinder 2 and the filling cylinder 3 are installed concentrically, there is a groove in the middle of the piston 4 that matches the filling cylinder 3, but the piston 4 It is still an integral structure to ensure the synchronization of the appearance and the filling.

[0015] The piston rod connecting the piston is connected to the power device. The piston rod is the screw 6. The screw 6 is used because the screw is stable, has a large force, and can be stopped at any time, without a brake device, which makes the whole noodle machine structure more Simple and compact. The screw 6 and the upper end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com