Optical display device

A technology for optical display and diffractive optical elements, which is applied in the field of augmented reality optical display devices and can solve problems such as difficulty in applying coating layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

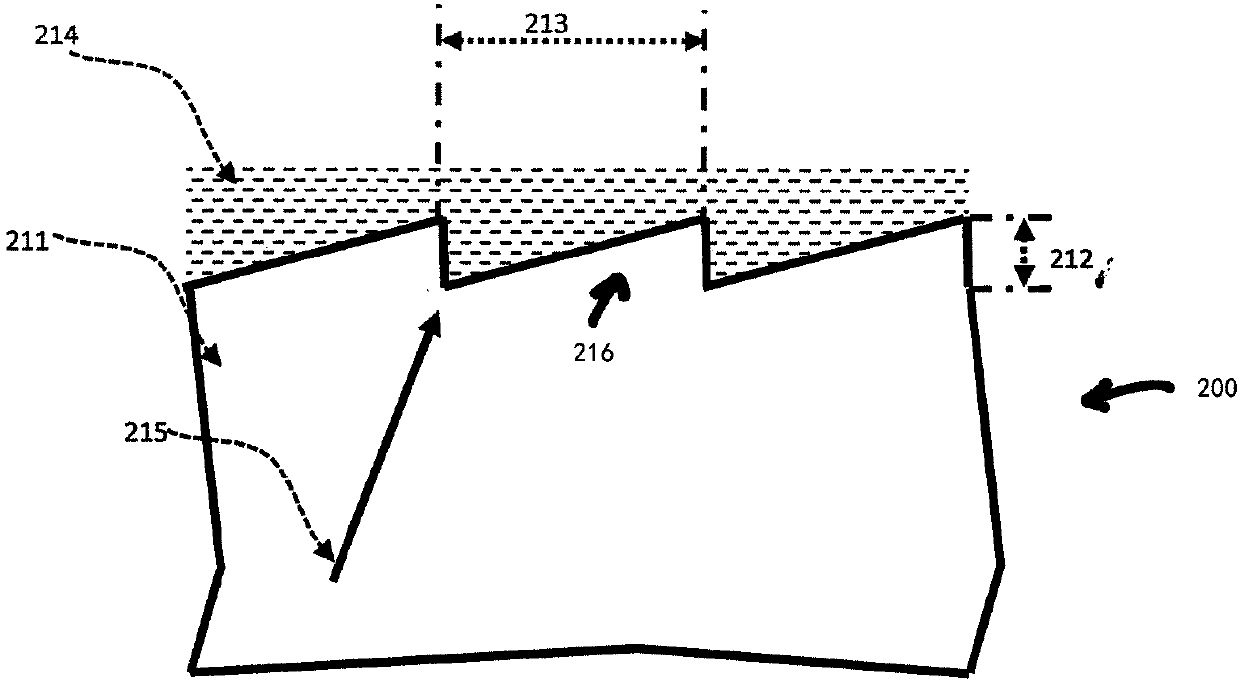

[0039] Figure 6 It is a cross-sectional view of the optical display device 600 in the embodiment of the present invention. The display device 600 includes an input diffractive optical element 618 mounted on a substrate 611 . The input diffractive optical element 618 comprises a blazed grating 619 with a period 613 of 520 nm and a feature height 612 of 220 nm. The input diffractive optical element 618 also includes a residual layer 617 formed from the same polymer-based material that forms the blazed grating 619 and produced simultaneously with the blazed grating 619 . Residual layer 617 is positioned adjacent to substrate 611 . The depth of the residual layer 617 is consistent across the blazed grating 619 . In this example, the residual layer depth is 80nm. On the surface of the blazed grating 619 a silver coating 614 is applied. The substrate 611 is generally made of glass and has a refractive index of 1.5. The refractive index of the input diffractive optical element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com