Energy absorbing box provided with concave polygonal section and provided with fold at one end

A concave polygon and energy-absorbing box technology, which is applied in vehicle safety arrangements, bumpers, non-rotational vibration suppression, etc., can solve the problems that are not suitable for the use of energy-absorbing boxes and cannot provide ultra-high specific energy absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

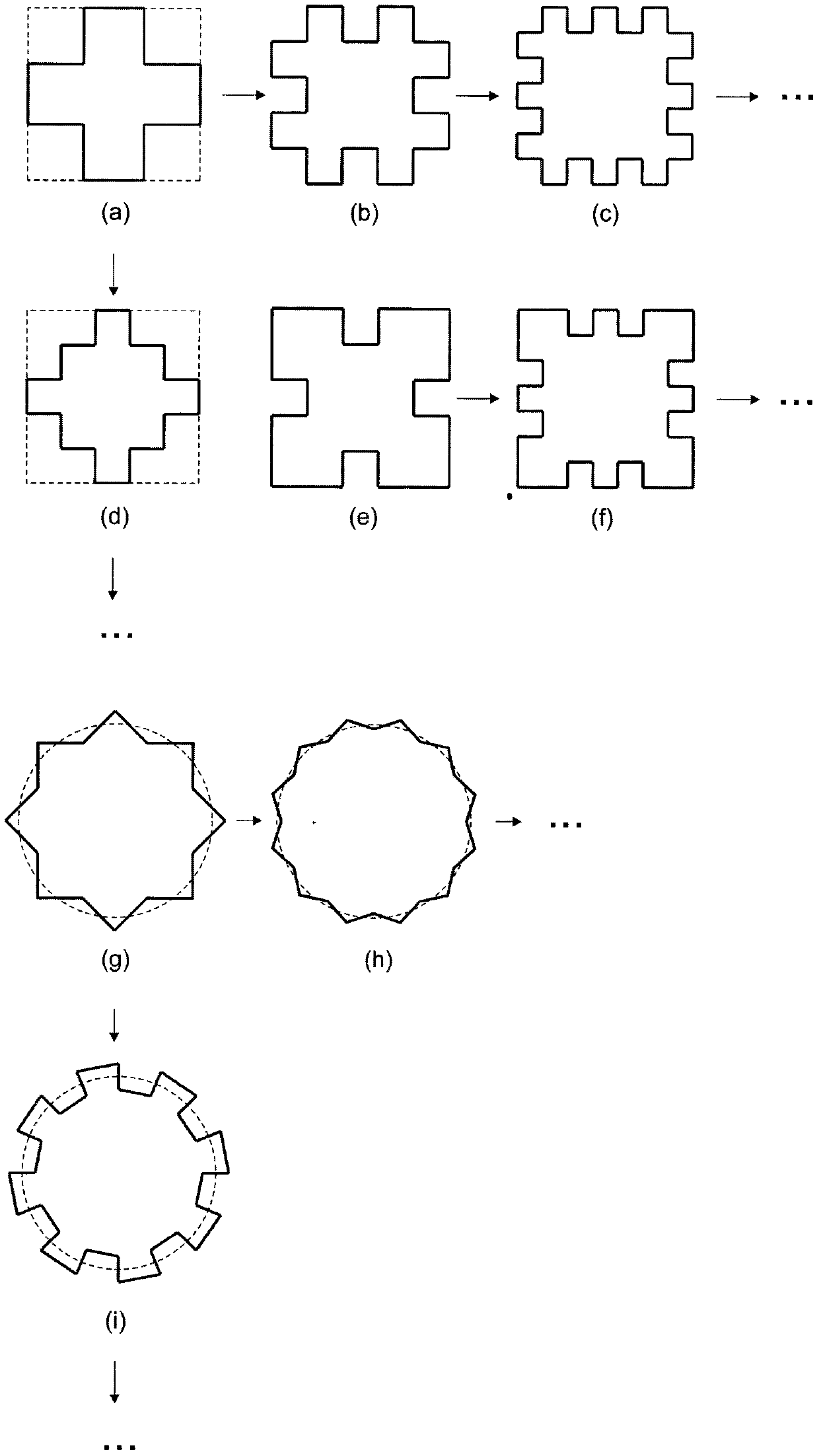

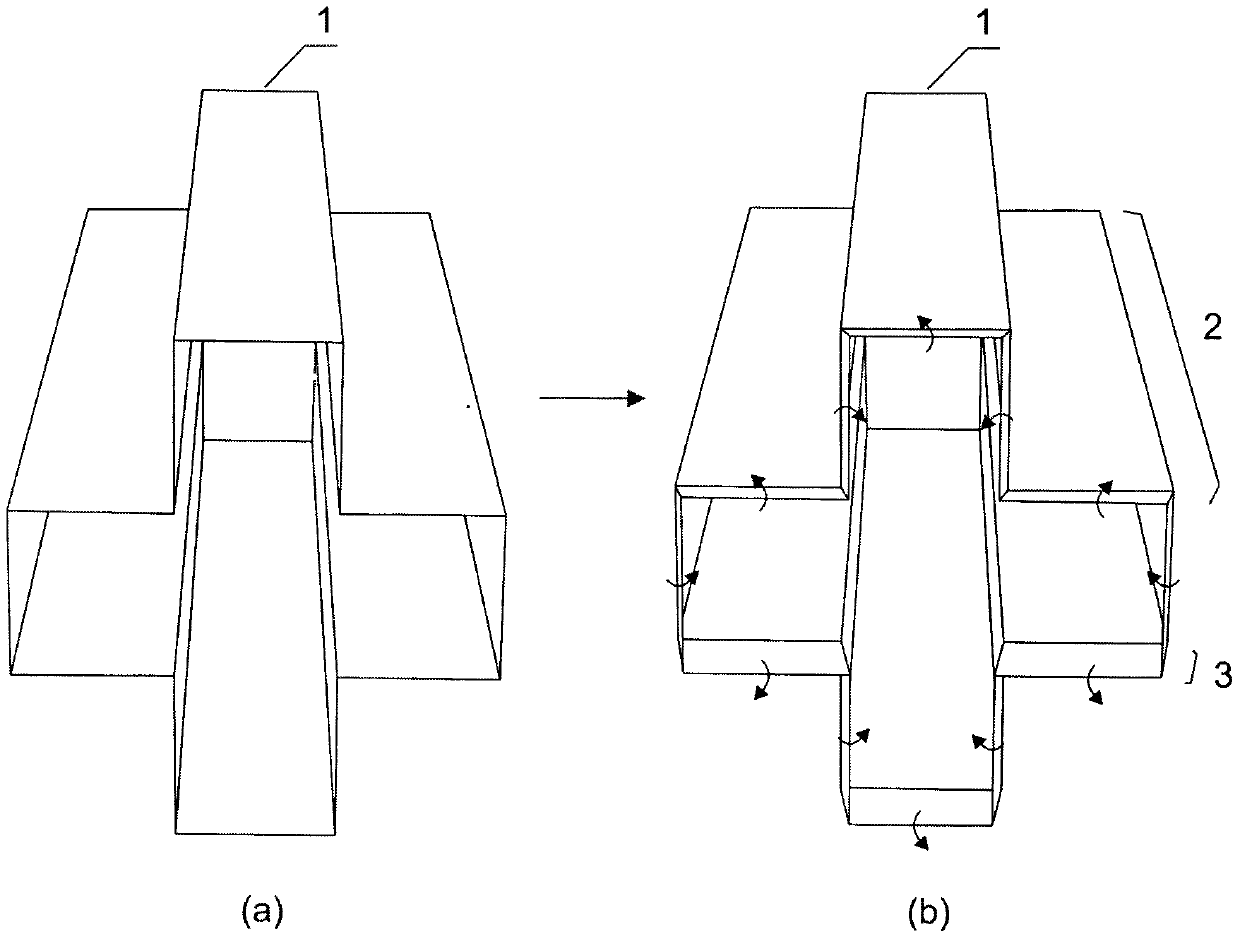

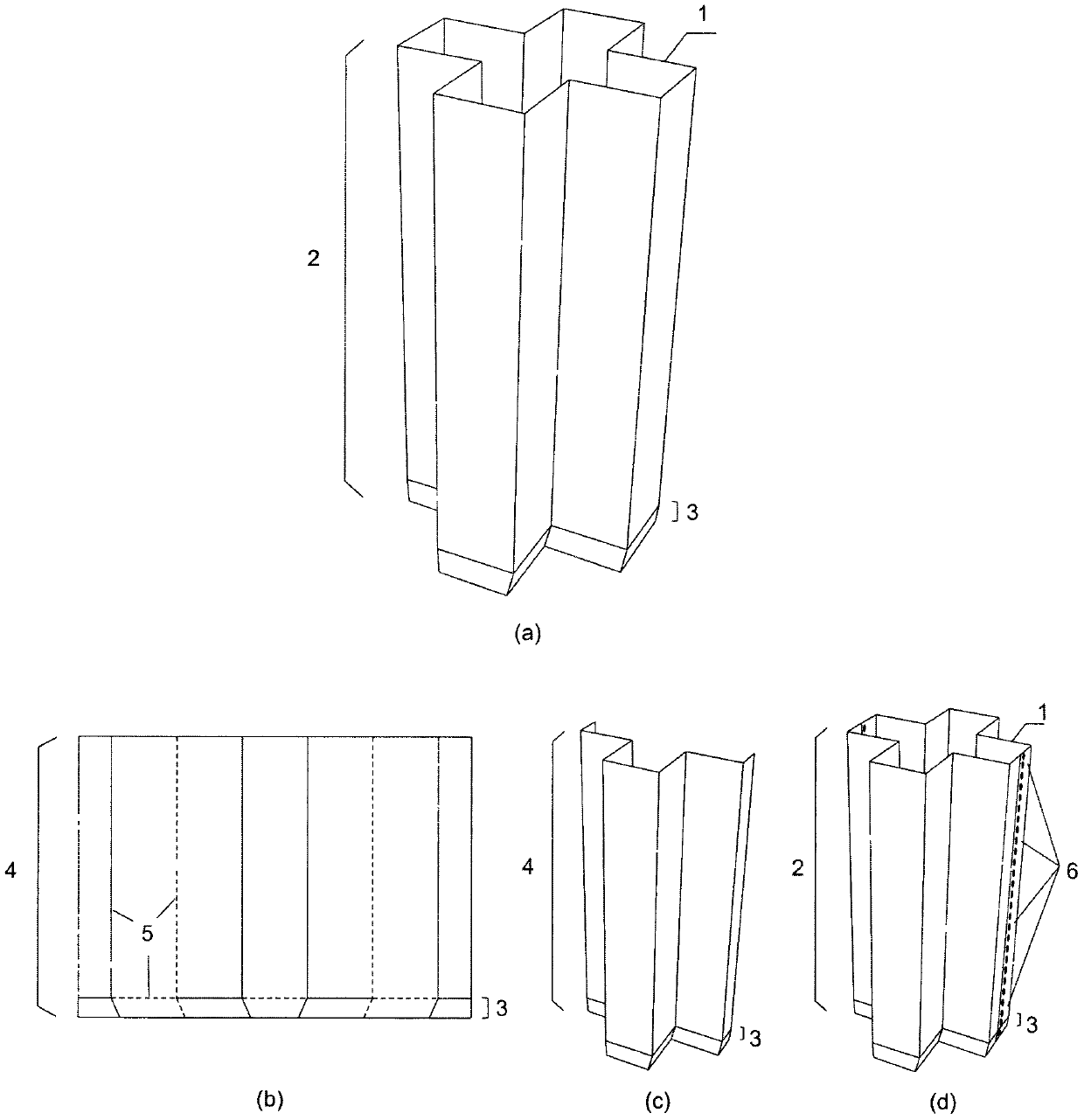

[0022] Embodiment 1: with figure 1 (a) An embodiment of a constant-section crash box with a crease at one end of the middle section as an example.

[0023] The first step is to determine the cross-sectional form, to figure 1 (a) The middle section as an example. The second step is to choose the processing method, taking the use of plate pressing as an example. There are roughly two ways to use plate pressing: the first is through traditional methods such as pressing and welding. figure 2 The ordinary concave polygonal cross-section pipe shown in (a), and then one end thereof is bent to form a guiding crease 3, thereby forming an energy-absorbing box 2, as figure 2 (b); The second is to press two (or several) shells 4 respectively by a mold with a concave polygonal cross section and creases, such as image 3 As shown in (c), then two (or several) shells 4 are connected (welded) together through a fixed point 6 to form a complete energy-absorbing box 2, as image 3 (d), w...

Embodiment 2

[0024] Embodiment 2: An embodiment of a constant-section crash box with a crease at one end formed with other different cross-sections.

[0025] Figure 4 8 and 11 are respectively composed of section 7 ( figure 1 (b)) and 10( figure 1 (h)) Schematic diagram of the formed crash box, 9 and 12 are its creases. These two cross-sections and other concave polygonal cross-sections can be made into corresponding crash boxes in the same manner as in Embodiment 1.

Embodiment 3

[0026] Embodiment 3: with figure 1 (d) An embodiment of a variable cross-section crash box with a crease at one end of the middle cross-section as an example.

[0027] The variable-section crash box design helps to increase the compression stroke of the crash box. Figure 5 , based on section 13( figure 1 (d)), 14 is its corresponding constant-section crash box, and 16 and 18 are corresponding variable-section crash boxes formed in different ways. Figure 6 are the expanded plan views respectively. Manufacturing method refers to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com