Comfortable skin-caring multifunctional braided fancy yarn

A fancy yarn and multi-functional technology, applied in the field of textiles, can solve the problems of small fiber cohesion, high rigidity of mulberry fiber, and large difference in fiber length, etc., to reduce winding hairiness, maintain elasticity and physical and mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

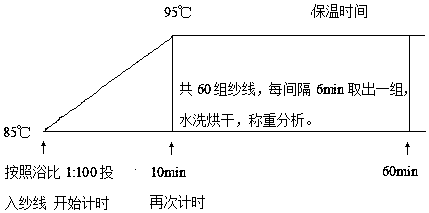

Method used

Image

Examples

Embodiment 1

[0168] In the present embodiment, the braid fancy yarn is a hollow braid yarn, which is made of fixed yarn, decorative yarn and core yarn, and the core yarn is bamboo charcoal fiber, isatis root fiber, copper fiber, chitin fiber, water-soluble vinylon filament Processed core-spun yarn; fixed yarn is blended yarn made of negative ion polypropylene fiber and glossy polyester fiber; decorative yarn is strong twisted yarn blended with rabbit hair fiber and hemp fiber. The weight percentage of each substance in the core yarn is: 70% bamboo charcoal fiber, 10% isatis root fiber, 10% copper fiber and 10% chitin fiber; the weight percentage of each substance in the fixed yarn is: 25% negative ion polypropylene fiber fiber and 75% bright polyester fiber; the percentage by weight of each material in the decoration yarn is: 20% rabbit hair fiber and 80% hemp fiber.

[0169] The first step core yarn preparation:

[0170] Opening and cleaning process: the general speed of the carding roll...

Embodiment 2

[0184] The preparation principle of the present embodiment is the same as that of Example 1, and the specific process parameters are as follows:

[0185] The percentage by weight of each substance in the core yarn of the braided yarn is: 10% bamboo charcoal fiber, 70% isatis root fiber, 10% copper fiber and 10% chitin fiber; the weight percentage of each substance in the fixed yarn is: 75% % negative ion polypropylene fiber and 25% glossy polyester fiber; the percentage by weight of each substance in the decorative yarn is: 75% rabbit hair fiber and 25% hemp fiber.

[0186] The first step core yarn preparation:

[0187] Opening and cleaning process: the general speed of the carding roller is 550r / min; the speed of the three-wing carding beater is 820r / min; the speed of the fan is generally 1300r / min, and the speed of the lap roller is 11.5 rpm.

[0188] Carding process: cylinder speed is 300r / min, licker-in speed is 700r / min, flat speed is 700mm / min, doffer speed is 28r / min; ...

Embodiment 3

[0201] The preparation principle of the present embodiment is the same as that of Example 1, and the specific process parameters are as follows:

[0202] The percentage by weight of each substance in the core yarn of the braided yarn is: 10% bamboo charcoal fiber, 10% isatis root fiber, 70% copper fiber and 10% chitin fiber; the percentage by weight of each substance in the fixed yarn is: 50% % negative ion polypropylene fiber and 50% glossy polyester fiber; the percentage by weight of each substance in the decorative yarn is: 40% rabbit hair fiber and 60% hemp fiber.

[0203] The first step core yarn preparation:

[0204] Opening and cleaning process: the general speed of the carding cylinder is 600r / min; the speed of the three-wing carding beater is 900r / min; the speed of the fan is generally 1400r / min, and the speed of the lap roller is 12.5 rpm.

[0205] Carding process: cylinder speed is 340r / min, licker-in speed is 860r / min, flat speed is 140mm / min, doffer speed is 30r / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com