Tin stripping liquid, method for removing tin-containing layer on base material and method for recycling simple substance tin

A technology for tin stripping and waste liquid, which is applied in the improvement of process efficiency, photography process, instruments, etc., and can solve the problems of strict condition control, complex process, secondary pollution and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

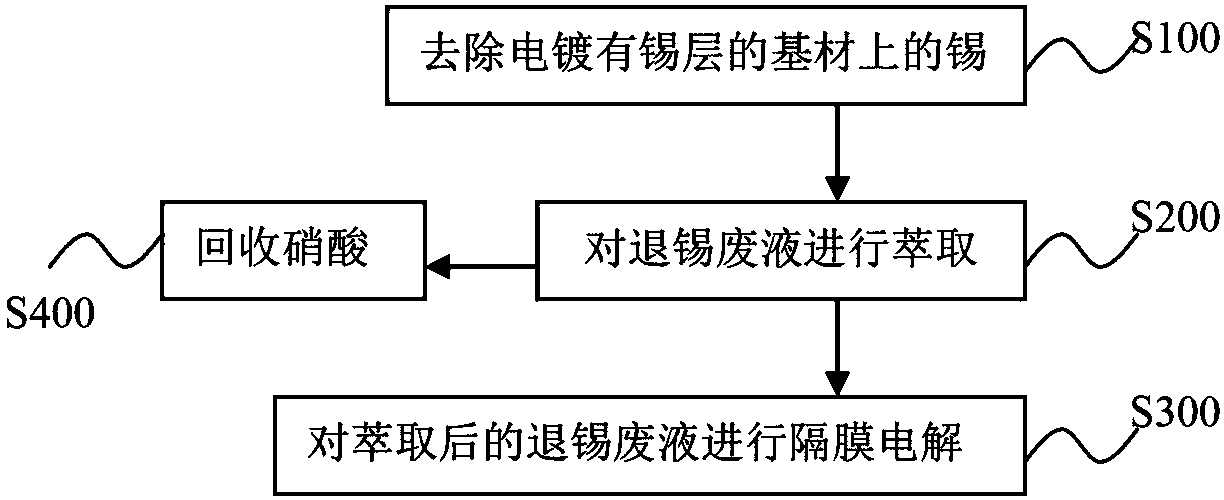

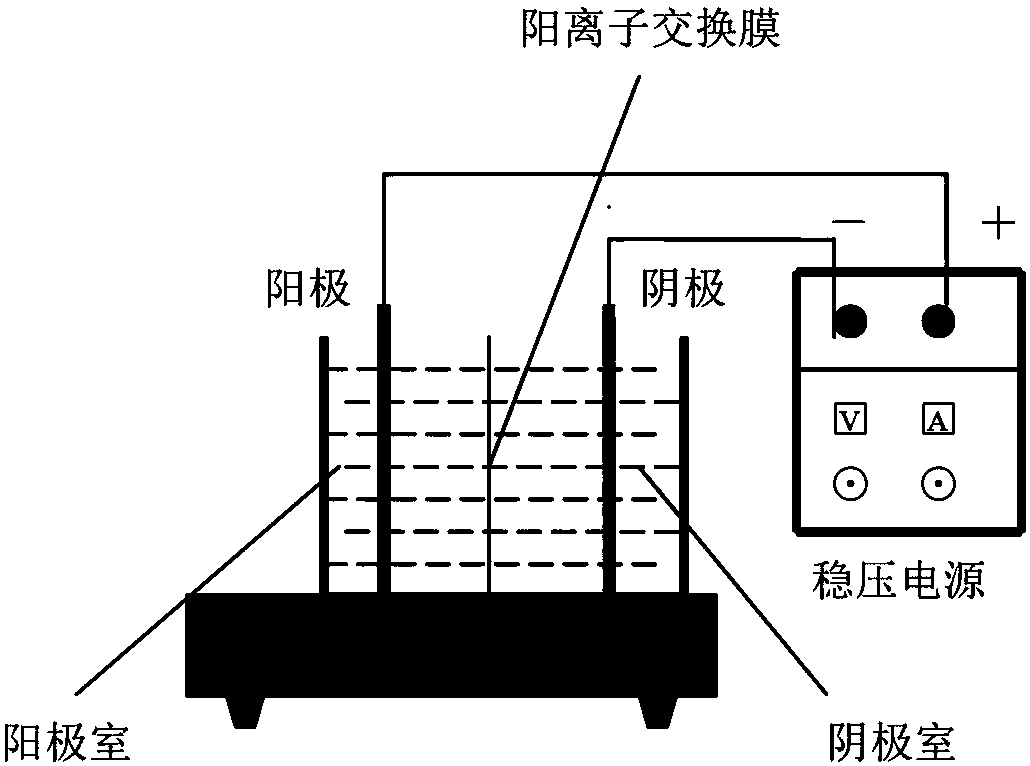

Method used

Image

Examples

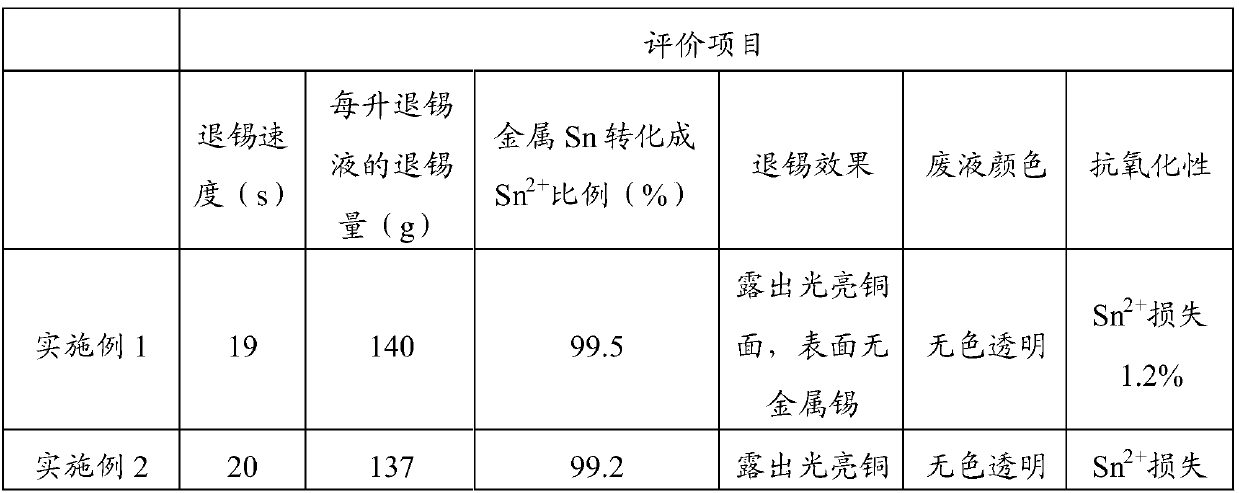

Embodiment 1

[0077] Embodiment 1: Preparation of tin stripping solution

[0078] Dissolve 50g of nitric acid, 200g of methanesulfonic acid, 20g of citric acid, 20g of thiourea, 60g of glycine and 5g of resorcinol in water to prepare 1L of tin stripping solution.

Embodiment 2

[0079] Embodiment 2: Preparation of tin stripping solution

[0080] Dissolve 75g of nitric acid, 150g of methanesulfonic acid, 12.5g of salicylic acid, 27.5g of acylurea, 30g of alanine and 10g of catechol in water to prepare 1L of tin stripping solution.

Embodiment 3

[0081] Embodiment 3: Preparation of tin stripping solution

[0082] Dissolve 100g of nitric acid, 300g of methanesulfonic acid, 70g of sulfamic acid, 50g of tartaric acid, and 0.5g of hydroquinone in water to prepare 1L of tin stripping solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com