Vertical pyrolysis furnace

A pyrolysis furnace, vertical technology, used in coke ovens, direct heating and dry distillation, petroleum industry and other directions, can solve the problems of affecting production progress, restricting continuous production of devices, and small number of jet pipes, etc., to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

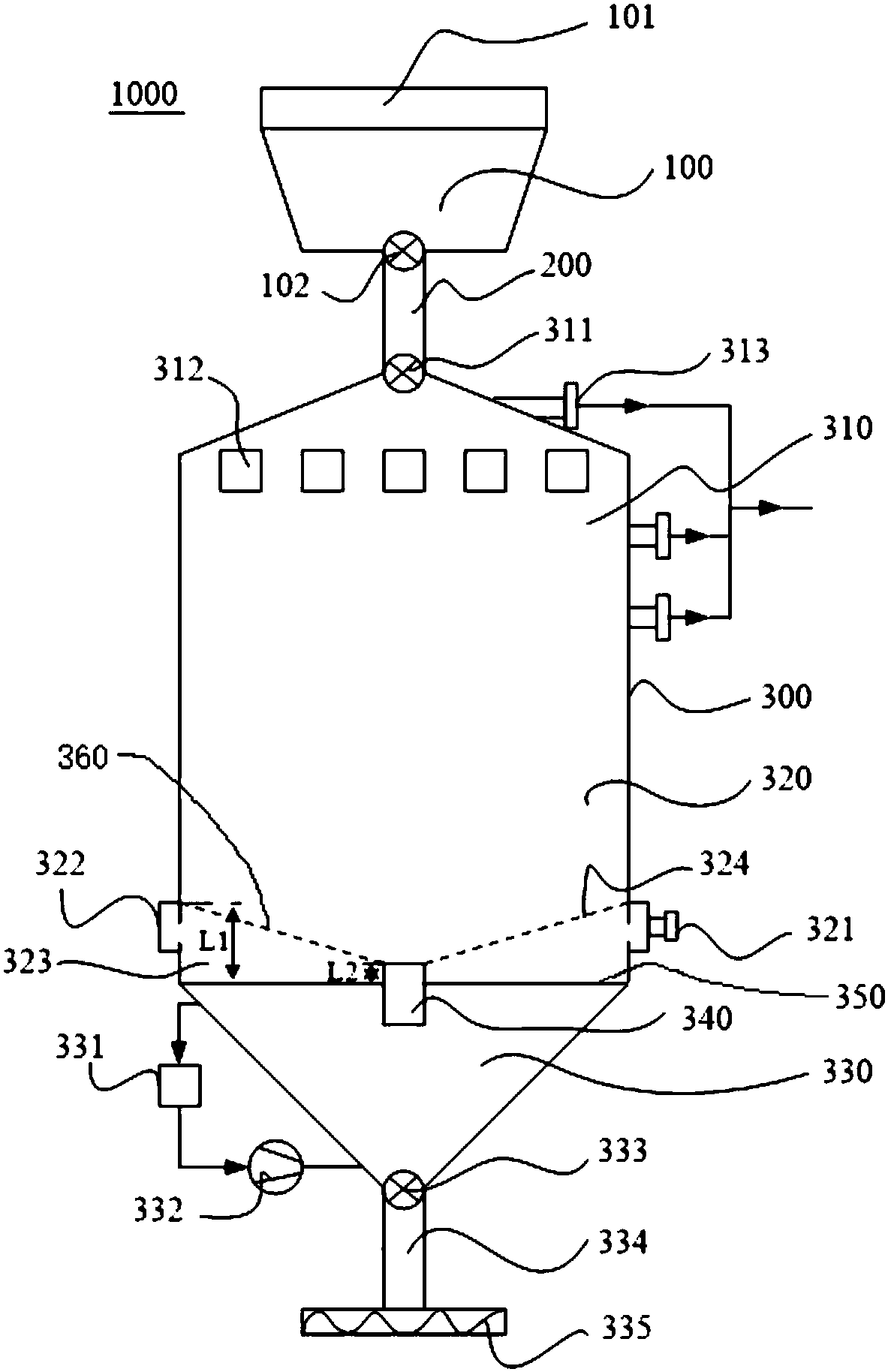

[0069] This example 1 uses figure 1 with figure 2 The vertical pyrolysis furnace 1000 shown as an example is as follows:

[0070] Using hot converter gas as the heat carrier gas to pyrolyze low-rank coal, specifically: converter gas flow rate is 25000Nm 3 / h, the temperature before entering the furnace is 1050℃, which contains about 65% of CO, CO 2 About 20%, N 2 About 15%. The converter gas is introduced from the heat-carrying gas inlet 321 at the bottom of the vertical pyrolysis furnace 1000, and the low-rank coal pellets or particles from the bottom up and down fully exchange heat, and the low-rank coal pellets or particles are heated to 950°C to promote low The rank coal undergoes a pyrolysis reaction, and the converter gas is mixed with the generated pyrolysis gas, and is discharged from the middle and upper part of the vertical pyrolysis furnace 1000 through the pyrolysis gas outlet 313. Among them, the particle size of low-rank coal pellets is 6-16mm, the pyrolysis capaci...

example 2

[0072] This example 1 uses figure 1 with figure 2 The shown vertical pyrolysis furnace 1000 is taken as an example, and the details are as follows:

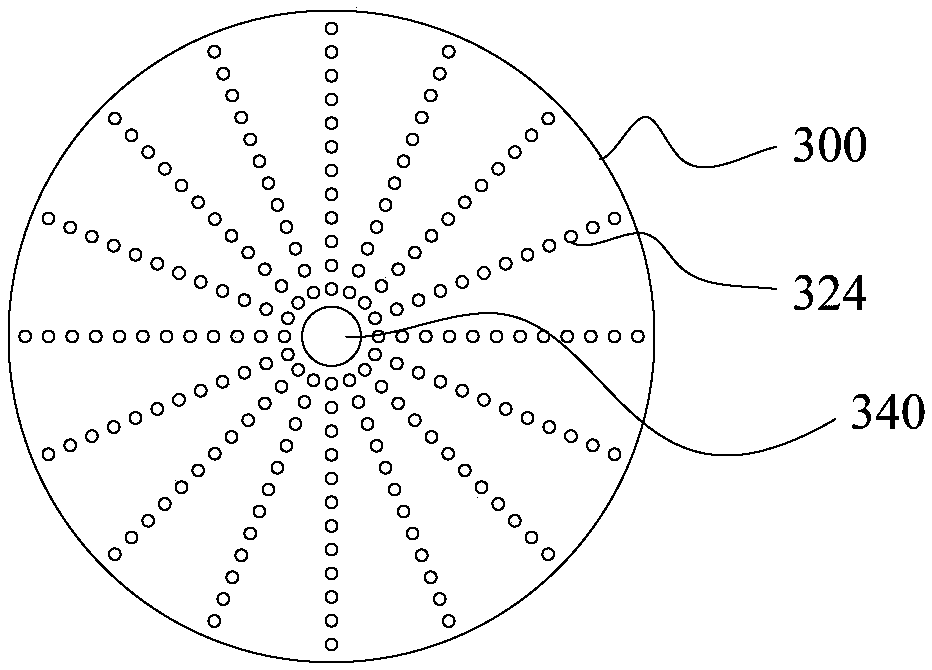

[0073] The temperature of the hot carrier gas before entering the furnace is 950℃, and the flow rate of the hot carrier gas is 30000Nm 3 / h, which contains about 75% of CO, CO 2 About 15%, N 2 About 10%. The heat-carrying gas is introduced from the nozzle 324 at the bottom of the vertical pyrolysis furnace 1000, and the lower-rank coal pellets or particles are fully heat exchanged from bottom to upper and descending, and the lower-rank coal pellets or particles are heated to 900°C to promote the lower-rank coal The pyrolysis reaction occurs, and the converter gas is mixed with the generated pyrolysis gas, and is discharged from the middle and upper part of the vertical pyrolysis furnace 1000 through the pyrolysis gas outlet 313. Among them, the particle size of low-rank coal pellets is 6-12mm, the pyrolysis capacity of low-rank coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com