Heating well used for in-situ repair engineering of contaminated site

An in-situ repair and heating well technology, applied in the restoration of contaminated soil, etc., can solve the problems of difficult access to large-scale electricity, high energy costs, and difficult treatment, and achieve pollutant concentration without rebound and thermal desorption temperature High effect with broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

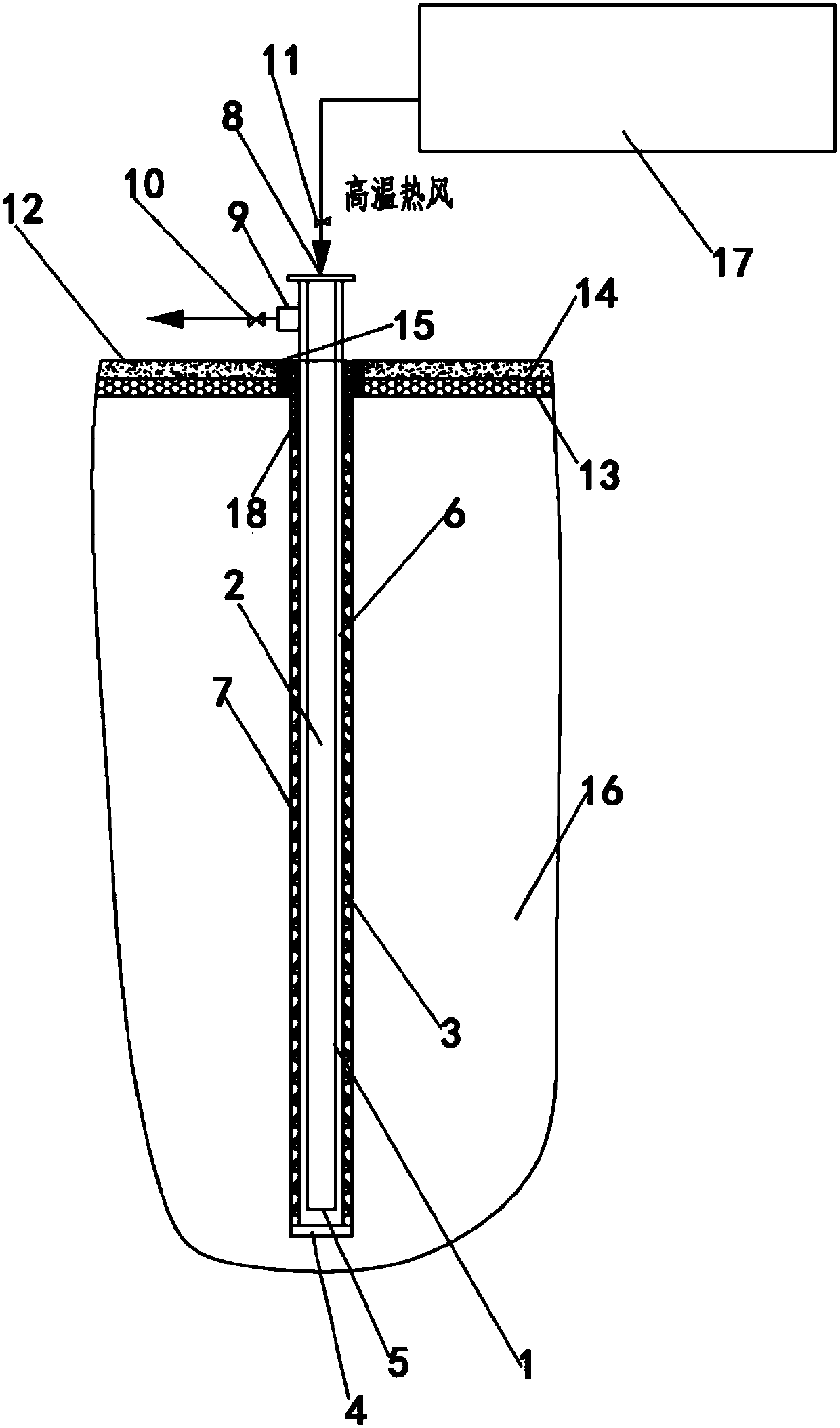

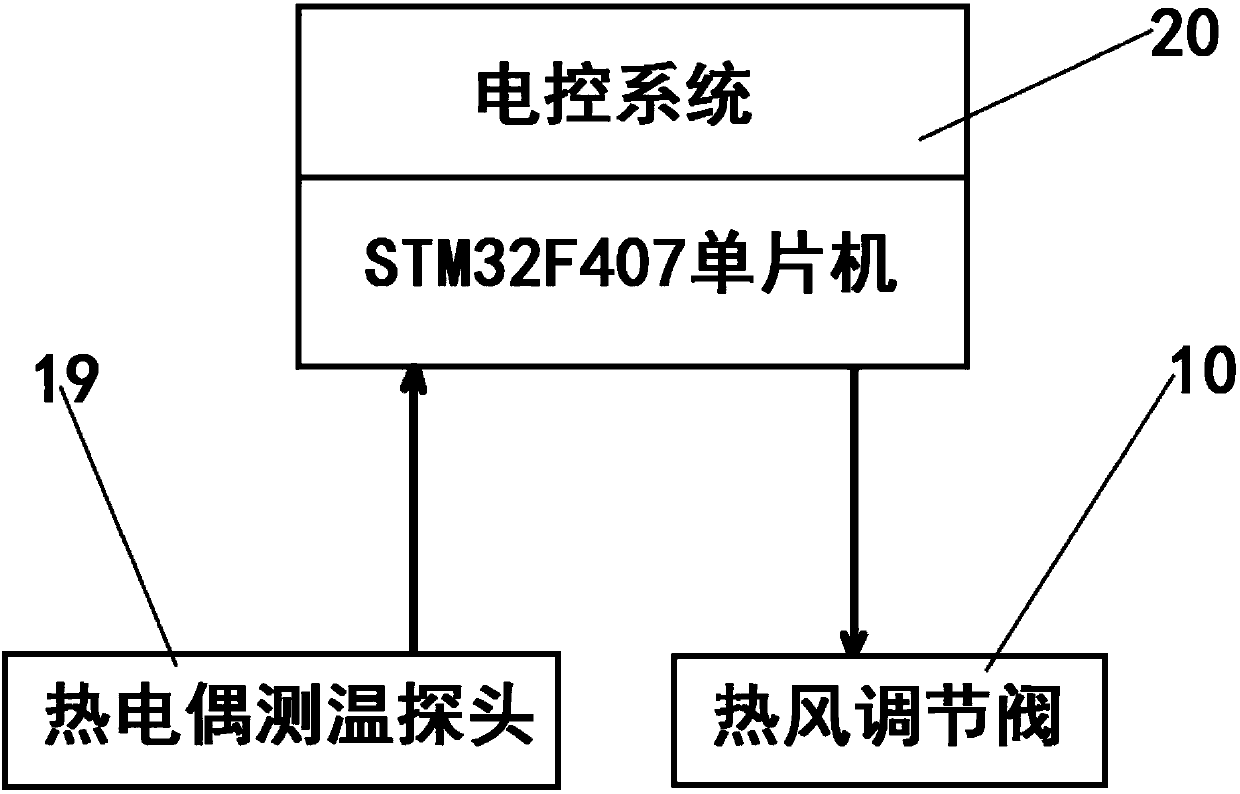

[0029] The heating well 1 is designed with inner and outer concentric casings. The diameter of the outer pipe 3 is 130 cm, and the diameter of the inner pipe 2 is 60 cm. It is made of stainless steel; the bottom of the outer pipe 3 is provided with a bottom cover 4, and the bottom of the inner pipe 2 is an opening 5 without a bottom cover. , 25cm away from the bottom of the outer tube 3. The high-temperature hot air is first fed into the bottom of the heating well 1 through the inner pipe 2 from top to bottom, and then returns to the ground through the gap 6 between the inner pipe 2 and the outer pipe 3 from bottom to top, and is discharged through a hot air outlet 9 arranged on the side. In order to achieve the purpose of equalizing the heat exchange temperature. The hot air outlet 9 is provided with a hot air regulating valve 10 .

[0030] When the heating well 1 is installed, there is generally a 20cm annular gap between the outer pipe 3 and the drilled soil hole, and cera...

Embodiment 2

[0035] The heating well 1 is designed and installed according to the pollution distribution in the in-situ repair area of the polluted site 16 to form a heating well group. The plane adopts the form of dense and uniform distribution of squares, and the well spacing is 1.5m; the vertical direction matches the repair depth and exceeds the pollution. Depth 0.5m.

[0036] According to the distribution of site pollution, the actual conditions of the site and the design characteristics of the system, a hot blast stove 17 is equipped with multiple heating wells 1, and multiple heating wells 1 are operated in parallel, and the amount of hot air entering each heating well 1 is adjusted as much as possible through valves. Possibly balanced.

[0037] The heating well 1 is in the form of inner and outer concentric casings, made of stainless steel; the inner tube 2 has a diameter of 50 cm, and the bottom is an opening 5 without a bottom cover; the outer tube 3 has a diameter of 125 cm, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com