Preparation method of salvia extract

An extract and technology of salvia miltiorrhiza, applied in the field of preparation of salvia miltiorrhiza extract, can solve the problems of salvianolic acid B being easily decomposed and destroyed, salvianolic acid B being unstable to heat, and high extraction temperature under reflux, so as to achieve high extraction efficiency and conditions Mild, less damaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

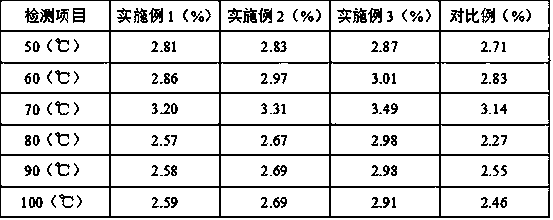

Examples

preparation example Construction

[0017] A preparation method of salvia miltiorrhiza extract, the method comprises the steps of:

[0018] (1) Put Salvia miltiorrhiza in a drying oven at 60°C for 1 to 2 hours, put it into a pulverizer, and pulverize it at 800r / min for 40min, collect the pulverized material, pass through a 200-mesh sieve, and collect the sieved particles;

[0019] (2) According to the mass ratio of 3-5:7-9:1, put the sieved particles, 1.8mol / L ethanol solution and carnosol into the ball mill, and perform ball milling at 700r / min for 50min, and collect the ball milling mixture. Put the ball mill mixture into a supercritical carbon dioxide device, extract at 10-12MPa, and collect the extract;

[0020] (3) According to the mass ratio of 7:1~2, put the extract and mixed enzyme into the container and mix them, let them stand at 32~35°C for 3 hours, put the container in an ultrasonic oscillator, and perform ultrasonication at 1.3MHz Shake for 70-90 minutes, filter, and collect the filtrate;

[0021]...

Embodiment 1

[0023] Mixed enzyme preparation: cellulase and enzyme protease are mixed at a mass ratio of 3:1,

[0024] A preparation method of salvia miltiorrhiza extract, the method comprises the steps of:

[0025] (1) Put the salvia miltiorrhiza in a drying oven at 60°C for 1.5 hours, put it into a pulverizer, and pulverize it at 800r / min for 40min, collect the pulverized material, pass it through a 200-mesh sieve, and collect the sieved particles;

[0026] (2) According to the mass ratio of 4:8:1, put the sieved particles, 1.8mol / L ethanol solution and carnosol into the ball mill, and conduct ball milling at 700r / min for 50min, collect the ball mill mixture, put the ball mill mixture in Into the supercritical carbon dioxide device, extract at 11MPa, and collect the extract;

[0027] (3) According to the mass ratio of 7:1.5, put the extract and the mixed enzyme into the container and mix them, let stand at 33°C for 3 hours, place the container in an ultrasonic oscillator, conduct ultras...

Embodiment 2

[0030] Mixed enzyme preparation: cellulase and enzyme protease are mixed at a mass ratio of 3:1,

[0031] A preparation method of salvia miltiorrhiza extract, the method comprises the steps of:

[0032] (1) Put the salvia miltiorrhiza in a drying oven at 60°C for 2 hours, put it into a pulverizer, and pulverize it at 800r / min for 40min, collect the pulverized material, pass through a 200-mesh sieve, and collect the sieved particles;

[0033] (2) According to the mass ratio of 5:9:1, put the sieved particles, 1.8mol / L ethanol solution and carnosol into the ball mill, and perform ball milling at 700r / min for 50min, collect the ball milled mixture, put the ball milled mixture in Into the supercritical carbon dioxide device, extract at 12MPa, and collect the extract;

[0034] (3) According to the mass ratio of 7:2, put the extract and the mixed enzyme into the container and mix, let stand at 35°C for 3 hours, place the container in an ultrasonic oscillator, conduct ultrasonic vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com