Dual-head and full-automatic terminal machine for harness

A fully automatic, terminal machine technology, applied in the direction of line/collector parts, electrical components, circuits, etc., can solve the problems of long time, affecting the yield and quality of wiring harness, and restricting production efficiency, so as to improve the yield and reduce the The effect of reducing the amount of manual labor and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

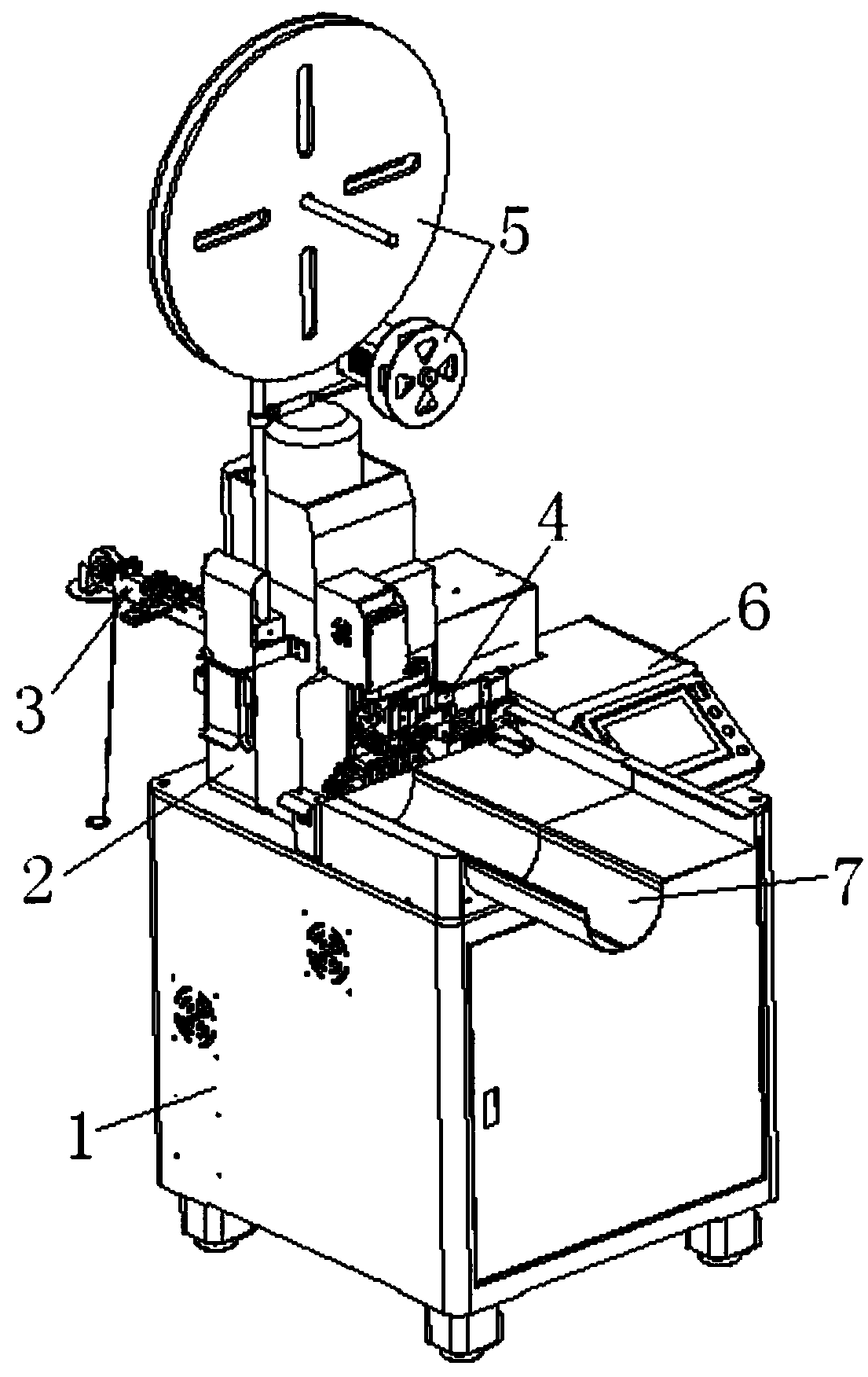

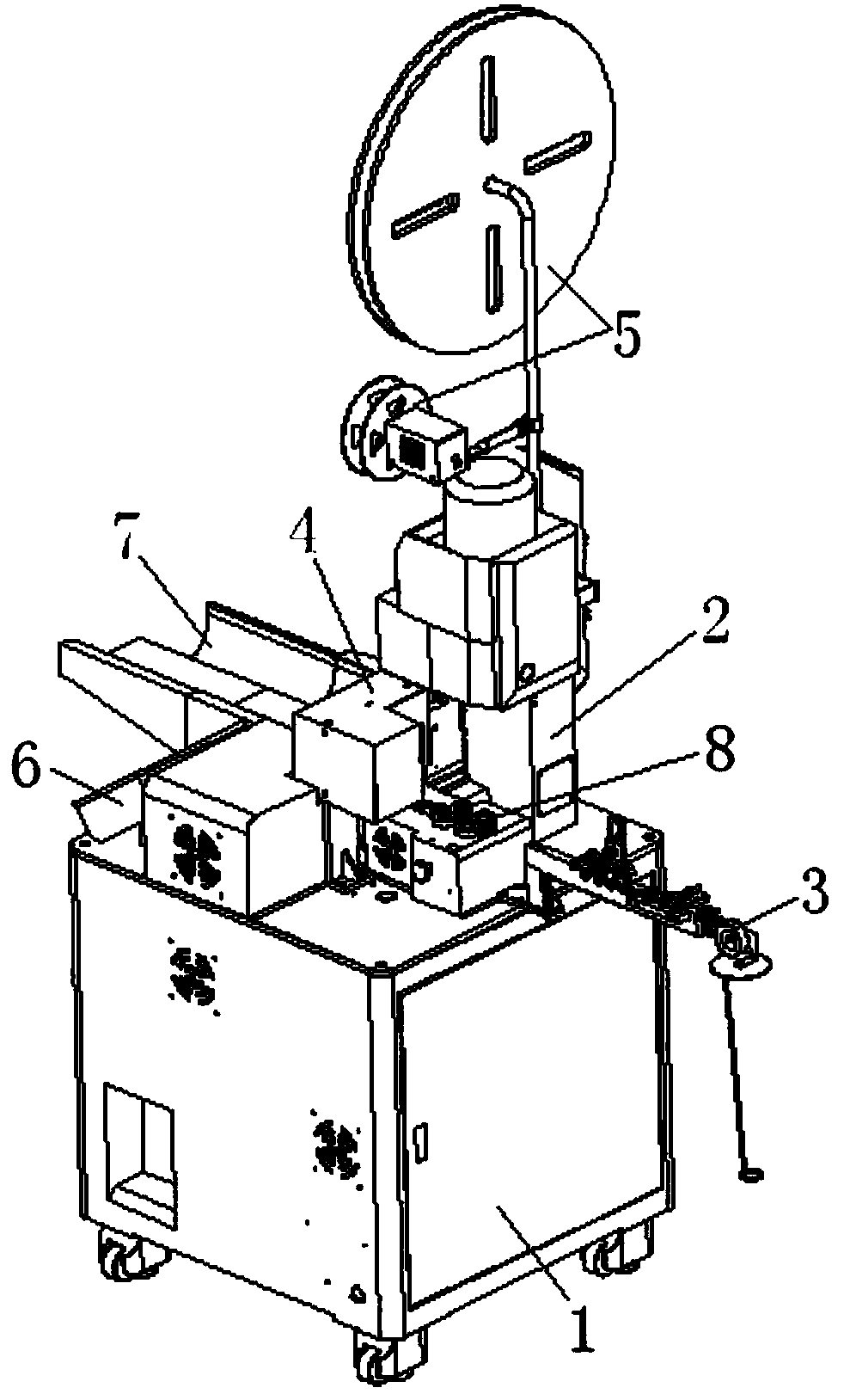

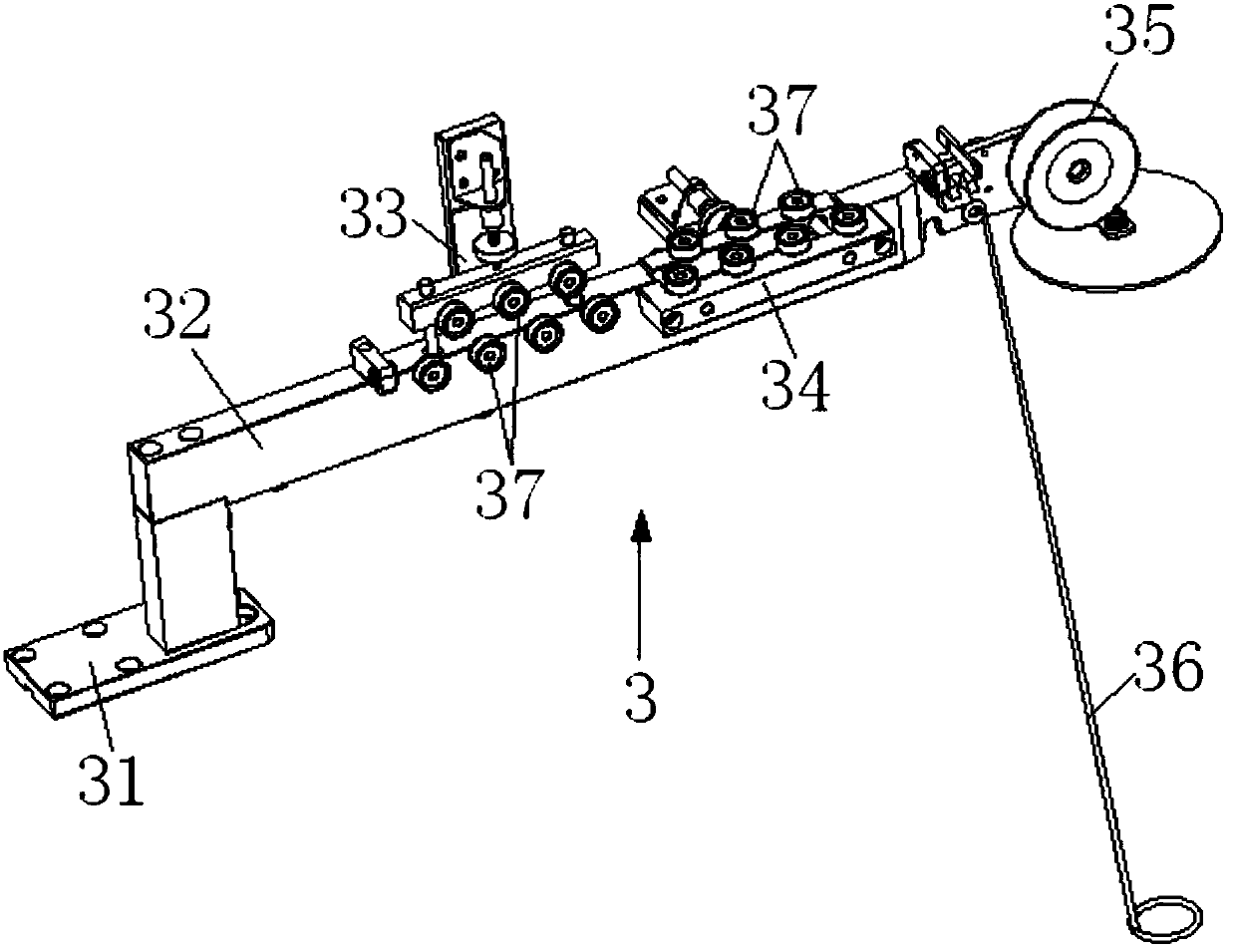

[0026] Refer to Figure 1 to 8 , A double-head fully automatic terminal machine for wire harnesses, comprising a chassis 1, and a fixed bottom frame 2 fixedly mounted on the top of the chassis 1, a rotating disc 5 is installed on the top of the fixed bottom frame 2, and a fixed bottom A conveying device 8 is placed on one end surface of the rack 2, and the bottom of the conveying device 8 is fixedly installed on the top of the chassis 1, and the top of the conveying device 8 is fixedly installed with a wire cutting terminal mechanism 4, a wire cutting terminal mechanism The top of 4 is attached to the bottom of the rotating disc 5, and the feeding device 3 is placed on the outer end of the feeding device 8. The bottom of the feeding device 3 is fixedly installed on the top of the chassis 1. The wire cutting and terminal mechanism 4 A receiving device 7 is placed on one side of the end surface, the bottom of the receiving device 7 is fixedly installed on the top of the chassis 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com