Preparation method and device of diamond wire saw

A technology of diamond wire saw and preparation device, which is applied to electrolytic coatings, coatings and other directions, can solve the problems of wear of preparation device, low sand loading efficiency, poor dispersibility, etc., and achieves low cost, high sand loading efficiency, and improved production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

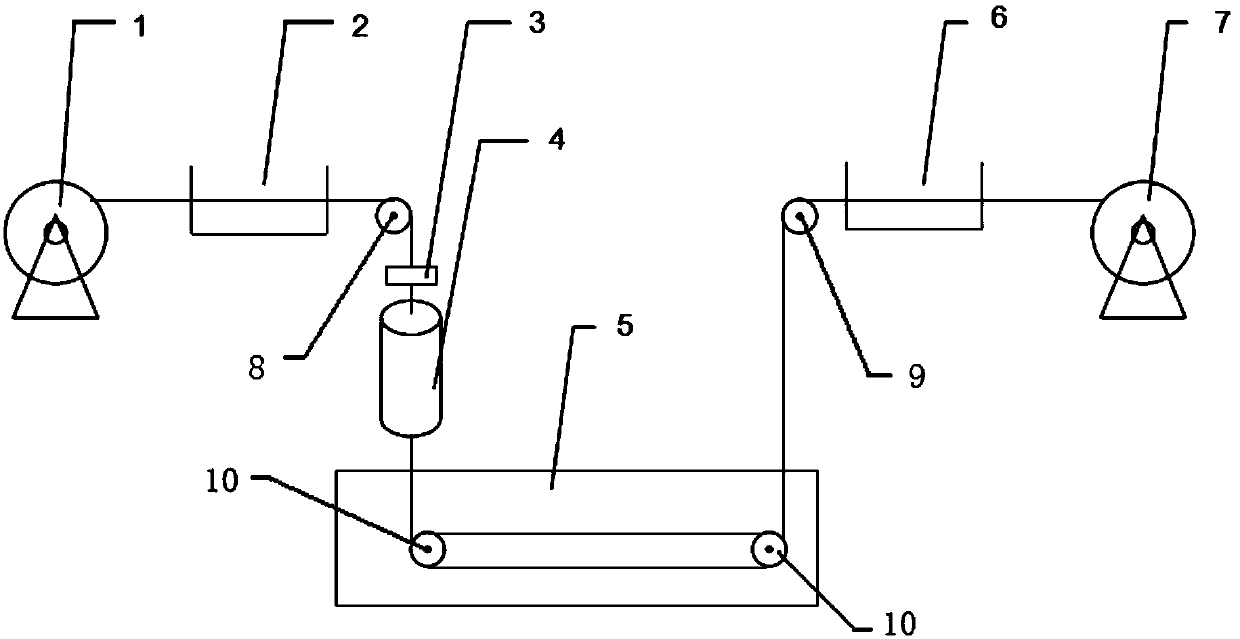

[0029] The invention provides a method for preparing a diamond wire saw, comprising the following steps: (1) performing polarization treatment on the surface of the diamond wire; (2) spreading the diamond wire after the polarization treatment in step (1) around the vertical embryo wire , the embryonic wire and the emery move downwards and make the emery adhere to the embryonic wire through an electrostatic field; (3) electroplating the embryonic wire adhered to the emery obtained in step (2) to obtain a diamond wire saw.

[0030] In the preparation method of the above-mentioned diamond wire saw, the corundum needs to be adhered to the embryonic wire through electrostatic action, so before the emery is used, it is firstly subjected to polarization treatment, so that the emery can better adhere to the embryonic wire in the electrostatic field . Continuously and evenly spread the corundum around the embryonic wire, and control its spreading density and range, so that the emery an...

Embodiment 1

[0050] A preferred embodiment of the present invention provides a method for preparing a diamond wire saw, comprising the following steps: (1) using a chemical method to polarize the surface of the emery with a particle diameter of 10 μm to cover it with a non-metallic layer; The surface of the embryonic thread is cleaned, dried and pretreated to keep the surface of the embryonic thread active. (2) Continuously disperse the above-mentioned corundum in the loose sand barrel 3, and spread the corundum evenly in the loose sand barrel 3 by stirring, and the density of the corundum around the embryo line is 30 cts / cm 3 , the embryo line and emery pass through the loose sand barrel 3 downwards and enter the upper sand barrel 4. The line speed of the embryonic line is 30m / min through the electrostatic field, and the direction of the electrostatic field is perpendicular to the embryonic line and points to the embryonic line from all around, with a strength of 1×10 6 v / m. (3) The emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com