Flexible dual-curing resin and preparation method thereof

A dual-curing, flexible technology, applied in the field of flexible dual-curing resin and its preparation, can solve the problem of incomplete curing, and achieve the effect of solving the curing depth and good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

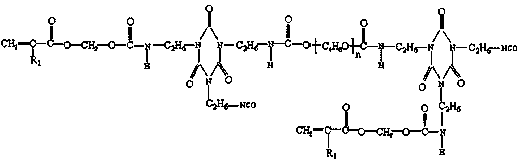

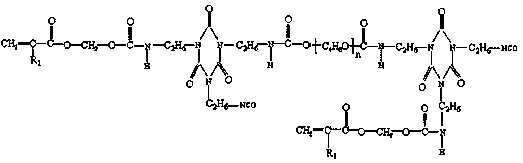

Image

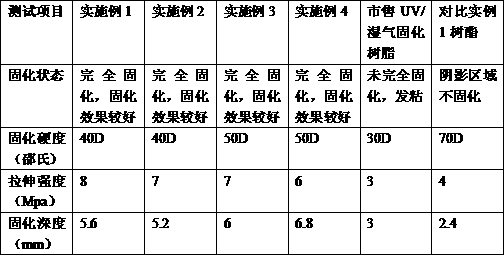

Examples

Embodiment 1

[0018] Add 65 g of hexamethylene diisocyanate trimer, 0.2 g of p-hydroxyanisole, and 1 g of antioxidant 2,6-di-tert-butyl-4-methylphenol into a three-necked flask with a thermometer, and start to heat up Stir, when the temperature reaches 50 degrees, slowly add 10g of hydroxyethyl acrylate, control the temperature at 75 degrees and react for 2 hours, test the NCO content, after the NCO content reaches 13+-0.5%, add the catalyst dibutyltin dilaurate 0.03g, Polytetrahydrofuran diol (2000) 17g, control the reaction temperature 80 degrees, react for 3 hours, take a sample to test the NCO content and viscosity, the NCO content is 7-9%, when the viscosity is controlled to 50000-80000CP, cool down and discharge the material, and the soft double Cured resin.

Embodiment 2

[0020] Add 64g of isophorone diisocyanate trimer, 0.2g of p-benzoquinone, and 1g of antioxidant triphenyl phosphite into a three-necked flask with a thermometer, start heating and stirring, and slowly add acrylic acid when the temperature reaches 50 degrees 8g of hydroxyethyl ester, control the temperature at 75 degrees for 3 hours, test the NCO content, after reaching the NCO content of 13+-0.5%, add the catalyst dibutyltin dilaurate 0.03g, polytetrahydrofuran diol (1000) 15g, control the reaction The temperature is 80 degrees, react for 3 hours, take a sample to test the NCO content and viscosity, the NCO content is 7-9%, when the viscosity is controlled to 50000-80000CP, cool down and discharge the material to obtain a flexible dual-cure resin.

Embodiment 3

[0022] Add 60 g of hexamethylene diisocyanate trimer, 0.2 g of hydroquinone, and 1 g of antioxidant 2,6-di-tert-butyl-4-methylphenol into a three-necked flask with a thermometer, and start heating and stirring When the temperature reaches 50 degrees, slowly add 10g of hydroxypropyl acrylate, control the temperature at 72 degrees and react for 2.5 hours, test the NCO content, after the NCO content reaches 13+-0.5%, add the catalyst dibutyltin dilaurate 0.03g, poly Tetrahydrofuran diol (3000) 20g, control the reaction temperature 83 degrees, react for 3 hours, take a sample to test the NCO content and viscosity, meet the requirements, the NCO content is 7-9%, and the viscosity is controlled at 50000-80000CP. After cooling down, the material is obtained. Flexible UV / moisture dual cure resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com