A kind of integrated defoaming method of bird's nest protein liquid

A technology of protein liquid and bird's nest, which is applied in the field of integrated defoaming of bird's nest protein liquid, can solve the problems of unstable product quality, loss of bird's nest protein, and easy large-scale foaming, etc. good bubble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) After crushing the dried bird’s nest, pass it through a 80-mesh sieve, add 20 times its weight in water and soak for 12 hours, change the water every 3 hours during this period, and then wash it with water for 3 times, then add water to prepare bird’s nest with a mass concentration of 1%. liquid, simmer for 30 minutes in water;

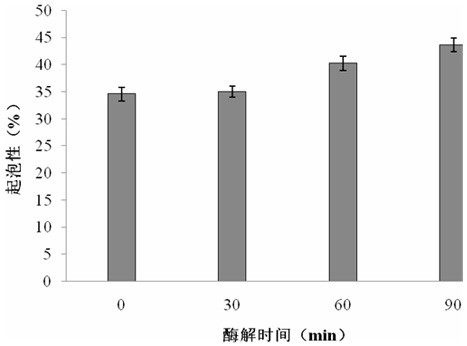

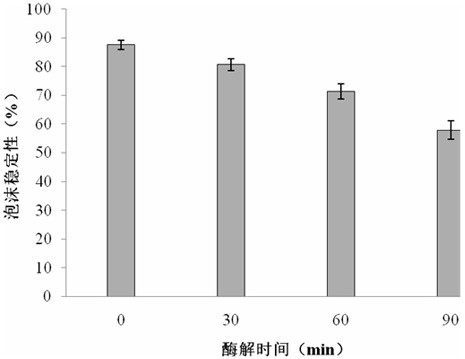

[0022] (2) Cool the stewed bird's nest liquid to 40°C, add 0.1mol / L NaHCO 3 The pH value of the solution was adjusted to 8, and the enzyme activity was added to 2×10 5 U / g of alkaline protease, its addition is 0.03% of the dry bird's nest weight, partially enzymolyzed for 30 minutes, until the degree of hydrolysis of the enzymolyzed solution is 5%, immerse in boiling water to kill the enzyme for 3 minutes;

[0023] (3) Cool the enzymolyzed solution after deactivation to 5°C, put it into a vacuum beater, beat at a low speed of 3,000 rpm for 2 minutes at 5°C and a vacuum of 0.06 MPa, and then use 10,000 Turn / min high-speed whipping for 2 mi...

Embodiment 2

[0027] (1) After crushing the dried bird’s nest, pass it through a 80-mesh sieve, add water 20 times its weight and soak for 12 hours, change the water every 3 hours during this period, and then wash it with water for 3 times, then add water to prepare bird’s nest with a mass concentration of 3%. liquid, simmer for 30 minutes in water;

[0028] (2) Cool the stewed bird's nest liquid to 50°C, add 0.1mol / L NaHCO 3 The pH value of the solution was adjusted to 8, and the enzyme activity was added to 2×10 5 U / g of alkaline protease, its addition is 0.04% of the dry bird's nest weight, partial enzymolysis for 60 minutes, until the degree of hydrolysis of the enzymatic solution is 10%, immerse in boiling water to kill the enzyme for 3 minutes;

[0029] (3) Cool the enzymatic hydrolysis solution after deactivation to 15°C, put it into a vacuum beater, beat at a low speed of 5000 rpm for 1min at 15°C and a vacuum of 0.08MPa, and then use 12000 Turn / min high-speed whipping for 1min; ...

Embodiment 3

[0033] (1) After crushing the dried bird’s nest, pass it through a 80-mesh sieve, add water 20 times its weight and soak for 12 hours, change the water every 3 hours during this period, and then wash it with water for 3 times, then add water to make bird’s nest with a mass concentration of 2%. liquid, simmer for 30 minutes in water;

[0034] (2) Cool the stewed bird's nest liquid to 60°C, add 0.1mol / L NaHCO 3 The pH value of the solution was adjusted to 8, and the enzyme activity was added to 2×10 5 U / g of alkaline protease, its addition is 0.05% of the dry bird's nest weight, partially enzymolyzed for 90min, until the degree of hydrolysis of the enzymolyzed solution is 15%, immerse in boiling water to kill the enzyme for 3min;

[0035] (3) Cool the enzymolysis solution after deactivation to 10°C, put it into a vacuum beater, beat at a low speed of 4,000 rpm for 2 minutes at 10°C and a vacuum of 0.07 MPa, and then use 11,000 Turn / min high-speed whipping for 2 minutes;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com