A kind of composite material of high-entropy alloy holding abrasive particles and its preparation method and application

A high-entropy alloy and abrasive particle technology, applied in the application field of high-entropy alloy, can solve the problems of high energy consumption, labor-intensive graphite mold, easy oxidation loss, unsuitable high-entropy alloy powder sintering and diamond matrix damage, etc., to achieve good Application Prospect, Irregular Particle Shape, Effect of Simplified Components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

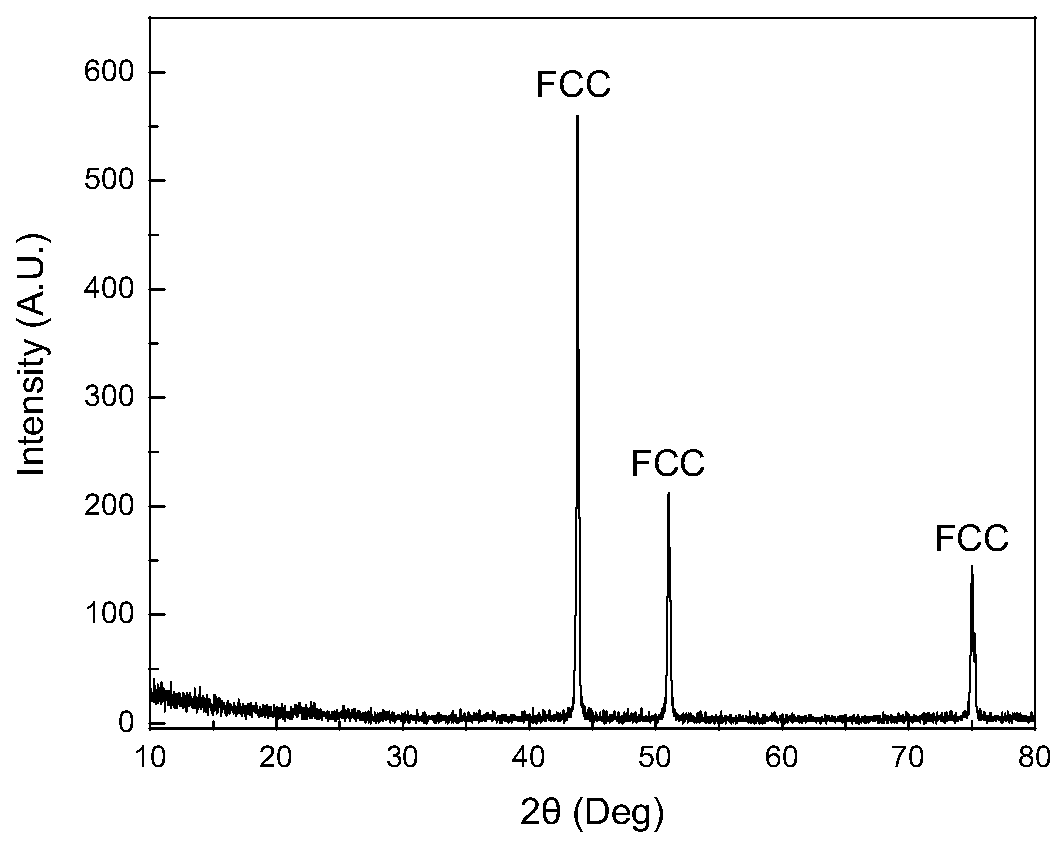

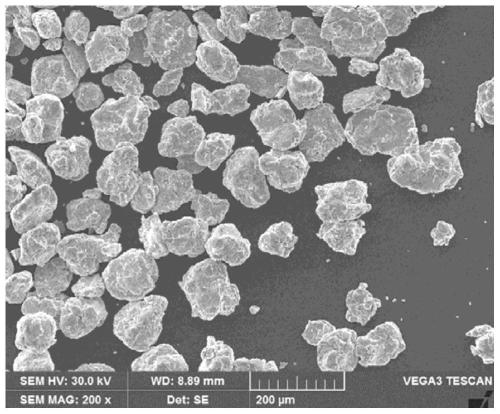

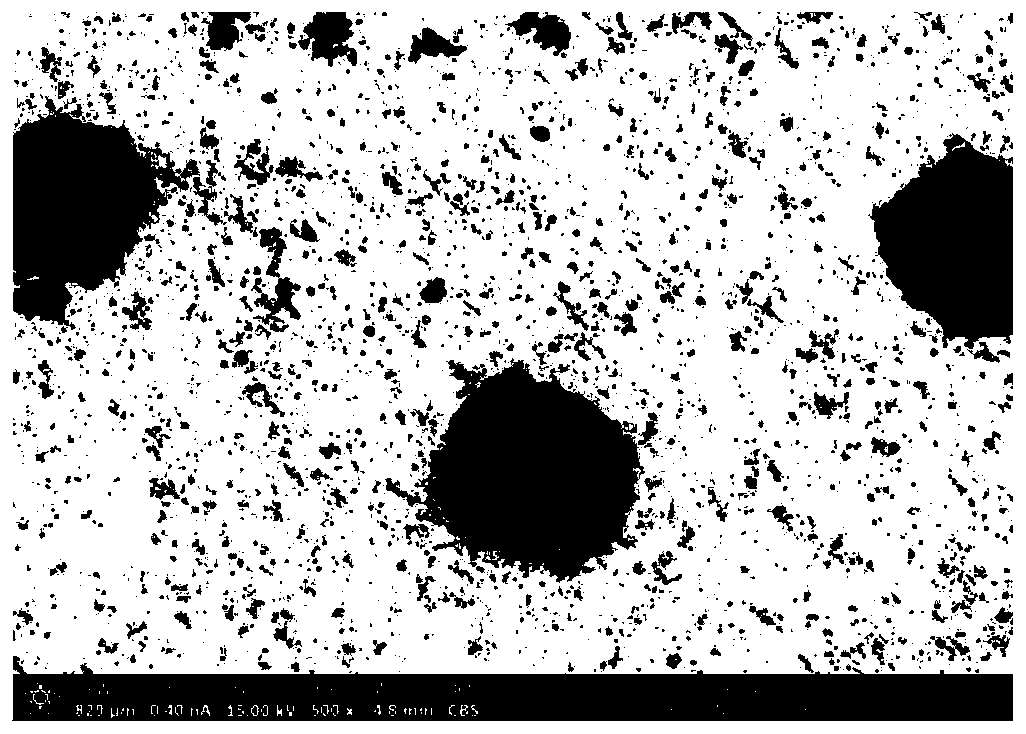

[0051] Preparation of FeCoCrNiCuMo Wrapped with Diamond with 5% Mass Ratio 0.1 High-entropy alloy cutter head: 1) Preparation of FeCoCrNiCuMo 0.1 High-entropy alloy formula powder, the raw materials are high-purity Fe, high-purity Co, high-purity Cr, high-purity Ni, high-purity Cu and high-purity Mo and other bulk metal materials, Fe, Co, Cr, Ni, Cu and Mo The atomic percentage is 1:1:1:1:1:0.1; it melts into a melt at 1500°C, and the melt is atomized and solidified quickly under a pressure of 2MPa. After sieving, 45-75um high-entropy alloy powder and alloy powder are obtained. Activation treatment was performed by ball milling for 10 hours at a ball-to-material ratio of 10:1 and a rotational speed of 200r / min. 2) Weigh the high-entropy alloy powder and diamond abrasive grains (the grain size of the abrasive grains is 100 microns) according to the mass ratio of 95:5, mix them evenly, and then sinter them in a spark plasma sintering furnace at a sintering temperature of T 1 =...

Embodiment 2

[0053] Preparation of FeCoCrNiCuMo Wrapped with 2% Diamond by Mass Ratio 0.1 High-entropy alloy cutter head: 1) Preparation of FeCoCrNiCuMo 0.1 High-entropy alloy formula powder, the raw materials are high-purity Fe, high-purity Co, high-purity Cr, high-purity Ni, high-purity Cu and high-purity Mo and other bulk metal materials, Fe, Co, Cr, Ni, Cu and Mo The atomic percentage is 1:1:1:1:1:0.1; it melts into a melt at 1500°C, and the melt is atomized and solidified rapidly under a pressure of 2.2MPa. After sieving, 45-75um high-entropy alloy powder, alloy The powder was activated by ball milling for 10h at a ball-to-material ratio of 10:1 and a rotational speed of 200r / min. 2) Weigh the high-entropy alloy powder and diamond abrasive grains (the grain size of the abrasive grains is 100 microns) according to the mass ratio of 98:2, mix them evenly, and then sinter them in a spark plasma sintering furnace at a sintering temperature of T1=900°C , the heating rate is v1=60°C / min, ...

Embodiment 3

[0055] Preparation of FeCoCrNiCuMo with Diamond Surrounding with 8% Mass Ratio 0.1 High-entropy alloy cutter head: 1) Preparation of FeCoCrNiCuMo 0.1 High-entropy alloy formula powder, the raw materials are high-purity Fe, high-purity Co, high-purity Cr, high-purity Ni, high-purity Cu and high-purity Mo and other bulk metal materials, Fe, Co, Cr, Ni, Cu and Mo The atomic percentage is 1:1:1:1:1:0.1; it melts into a melt at 1500°C, and the melt is atomized and rapidly solidified under a pressure of 2.1MPa. After sieving, 45-75um high-entropy alloy powder, alloy The powder was activated by ball milling for 10h at a ball-to-material ratio of 10:1 and a rotational speed of 200r / min. 2) Weigh the high-entropy alloy powder and diamond abrasive grains (the grain size of the abrasive grains is 100 microns) according to the mass ratio of 92:8, mix them evenly, and then sinter them in a spark plasma sintering furnace at a sintering temperature of T1=850°C , the heating rate is v1=60°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com