Novel external insulating anti-pollution flashover spraying composite material of electric transmission line

A technology for power transmission lines and composite materials, applied in antifouling/underwater coatings, fire retardant coatings, epoxy resin coatings, etc. Excellent self-cleaning performance and improved water repellency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

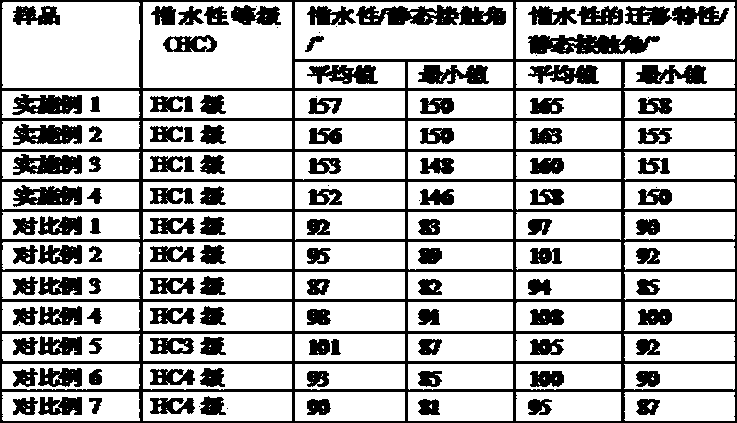

Examples

Embodiment 1

[0027] Example 1: A new anti-pollution flashover spray coating composite material for the external insulation of transmission lines, prepared from the following raw materials in parts by weight: 35 parts of silicone rubber, 25 parts of fluorosilicone resin modified epoxy resin, aluminate coupling 13 parts of agent, 5 parts of nano silicon dioxide, 2 parts of diatomaceous earth, 8 parts of calcium carbonate, 0.03 parts of tributyl phosphate, 4 parts of ethyl acetate, 3 parts of phosphate modified acrylic emulsion, fatty alcohol polyoxyethylene ether 0.3 parts, perfluoroalkyl ether sulfonate potassium salt F-53 0.002 parts, N-dodecyl ethanolamine 0.5 parts, propylene glycol methyl ether acetate 40 parts.

[0028] The silicone rubber of the present invention can be 107 room temperature vulcanized silicone rubber; nano-silica, preferably fumed silica. Fluorosilicone modified epoxy resin can be made by referring to the literature (Li Haiyang et al. Synthesis and performance researc...

Embodiment 2

[0037] Example 2: A new anti-pollution flashover spray coating composite material for the external insulation of transmission lines, prepared from the following raw materials in parts by weight: 35 parts of silicone rubber, 25 parts of fluorosilicone resin modified epoxy resin, aluminate coupling 13 parts of agent, 5 parts of nano silicon dioxide, 2 parts of diatomaceous earth, 8 parts of calcium carbonate, 0.03 parts of tributyl phosphate, 4 parts of ethyl acetate, 3 parts of phosphate modified acrylic emulsion, fatty alcohol polyoxyethylene ether 0.3 parts, perfluoroalkyl ether carboxylate potassium salt FC-5 0.002 parts, N-dodecyl ethanolamine 0.5 parts, propylene glycol methyl ether acetate 40 parts.

[0038] A method for preparing a novel anti-pollution flashover spray composite material for external insulation of transmission lines, comprising the following steps:

[0039] Step S1: Weigh calcium carbonate, nano silicon dioxide and diatomaceous earth, dry at constant temp...

Embodiment 3

[0046] Example 3: A new anti-pollution flashover spray coating composite material for the external insulation of transmission lines, prepared from the following raw materials in parts by weight: 38 parts of silicone rubber, 30 parts of fluorosilicone resin modified epoxy resin, aluminate coupling 16 parts of agent, 3 parts of nano-silica, 3 parts of diatomaceous earth, 7 parts of calcium carbonate, 0.03 parts of tributyl phosphate, 6 parts of ethyl acetate, 2 parts of phosphate-modified acrylic emulsion, polyethylene glycol 400 0.3 0.003 parts, potassium salt of perfluoroalkyl ether sulfonate F-530.003 parts, 0.5 parts of hydroxymethyl diethyl triamine, 45 parts of propylene glycol methyl ether acetate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com