Compounds, liquid crystal composition and liquid crystal display

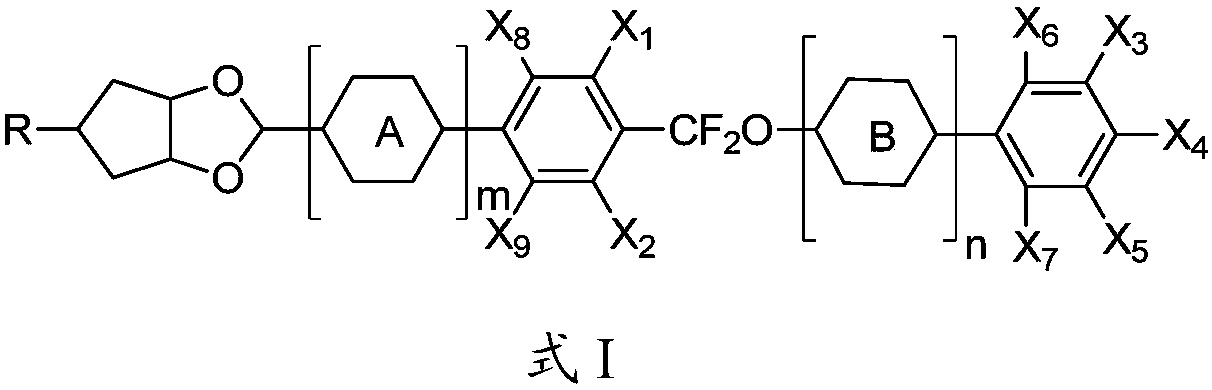

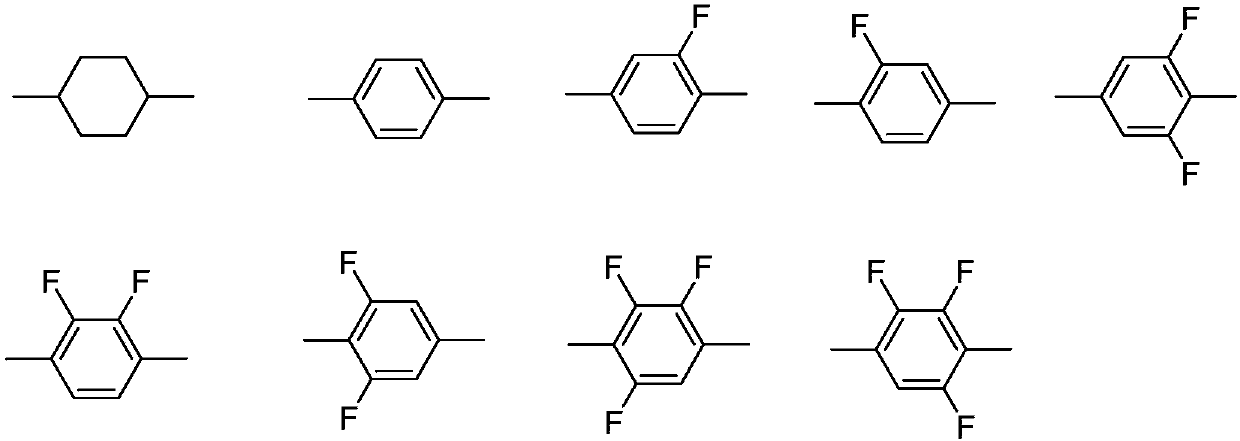

A liquid crystal composition, liquid crystal display technology, applied in the directions of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problem of low clearing point and dielectric constant of liquid crystal composition, narrow response speed, liquid crystal display can not be in high temperature state. Use the working temperature range and other issues to achieve the effect of increasing the working temperature range, improving the clearing point, and increasing the dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The specific compound synthesized is shown in formula P1:

[0063]

[0064] The synthetic route of P1 is as follows:

[0065]

[0066] First proceed to step 1:

[0067] The compound 3,4-dihydroxy-1-propylcyclopentane and 3,5-difluorobenzaldehyde are reacted in toluene to obtain the compound shown in formula P1-1, and the specific steps are:

[0068] In a 250ml three-necked flask, add 14.4 grams of 3,4-dihydroxyl-1-propylcyclopentane (prepared with reference to European Journal of Medicinal Chemistry 46 (2011) 1263-1273), 14.2 grams of 3,5-difluorobenzaldehyde, 100 milliliters of toluene was heated to 80 degrees to react for 4 hours, cooled, dried over magnesium sulfate, separated by silica gel column chromatography, and then recrystallized with a mixed solvent of ethanol and petroleum ether to obtain 15.0 grams of the compound shown in formula P1-1, with a yield of 56 %, product mass spectrum (m / e): 268, 1 HNMR (500MHz, CDCl 3 ), δ7.04(m, 2H), δ6.82(m, 1H), δ5...

Embodiment 2

[0079] The concrete compound of synthesis is shown in formula P7:

[0080]

[0081] The synthetic route of P7 is as follows:

[0082]

[0083] First proceed to step 1:

[0084] Compound 3,4-dihydroxyl-1-propylcyclopentane and p-bromobenzaldehyde are reacted in toluene to obtain the compound shown in formula P7-1, and the specific steps are:

[0085] In a 250ml three-necked flask, add 14.4 grams of 3,4-dihydroxy-1-propylcyclopentane (prepared with reference to European Journal of Medicinal Chemistry 46 (2011) 1263-1273), 18.5 grams of p-bromobenzaldehyde, 100 milliliters of toluene, Heated to 80 degrees to react for 4 hours, lowered the temperature, dried with magnesium sulfate, separated by silica gel column chromatography, recrystallized from a mixed solvent of ethanol and petroleum ether to obtain the product, 11.2 grams of the compound shown in formula P7-1, yield 36.01%, product mass spectrum (m / e): 310, 312, 1 HNMR (500MHz, CDCl 3 )δ7.78(m, 2H), δ7.30(m, 2H), δ5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com