Method for preparing imidodisulfuryl fluoride lithium

A technology of lithium bisfluorosulfonyl imide and bisfluorosulfonyl imide, which is applied in the field of preparation of lithium bisfluorosulfonyl imide, can solve problems such as high risk, high difficulty in operation, corrosion of equipment, etc., and achieve high product quality , The effect of low raw material price and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

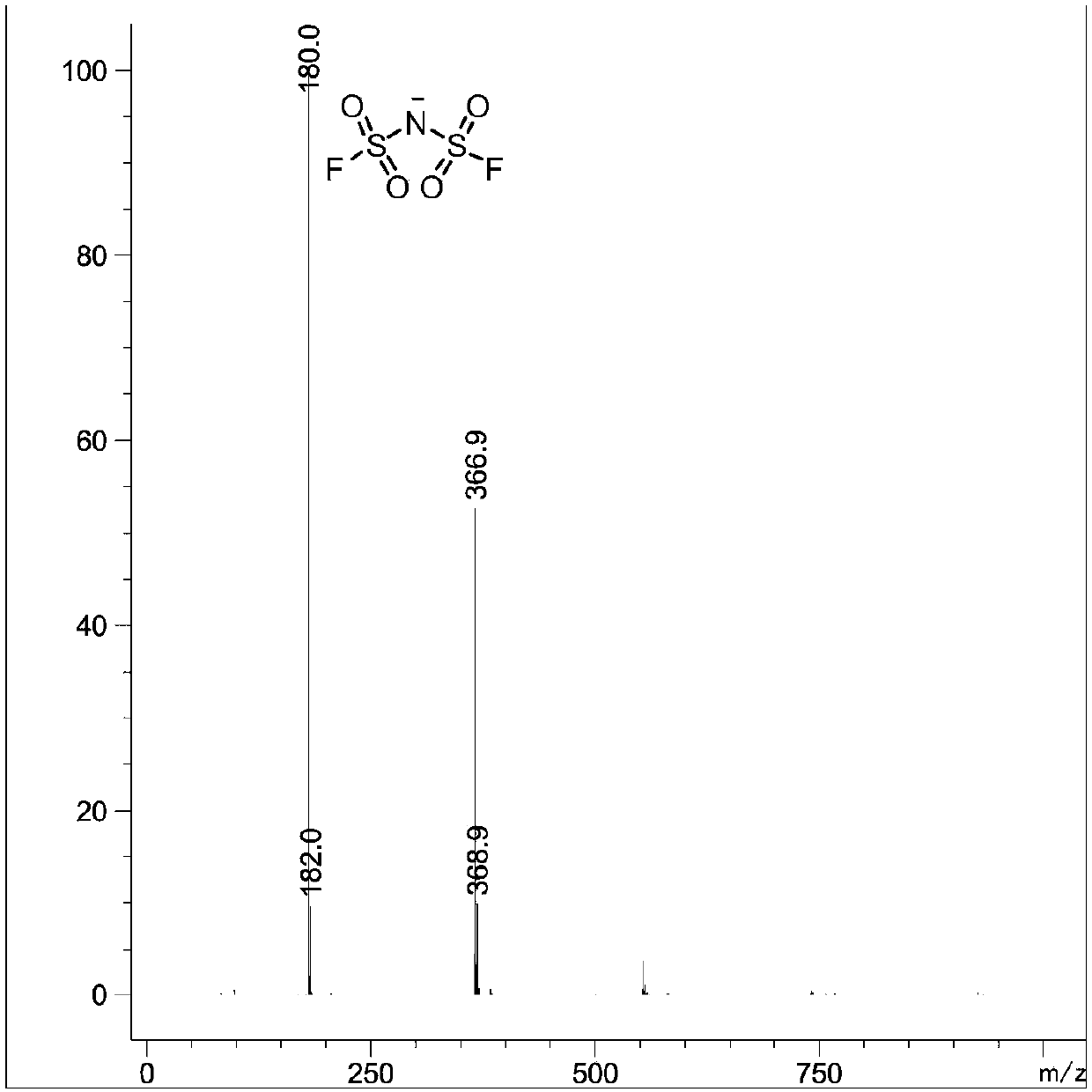

[0042] Under the protection of nitrogen, add 214g of bischlorosulfonimide into a 500ml reaction kettle, then add 161g of antimony trifluoride in batches, control the temperature during the process at 20-25°C, react for 20 hours, and then continuously distill under reduced pressure twice to obtain 162g The yield of bisfluorosulfonimide is 90%, and the purity is 99.5%.

Embodiment 2

[0044] Under the protection of flowing nitrogen, 200ml of anhydrous methanol was added to a 500ml reaction kettle, and then 1.4g of lithium metal was added. The process temperature was controlled below 40°C, and the reaction was stirred for 3 hours, and then concentrated to dryness under reduced pressure to obtain 7.6g of lithium methoxide. The yield 100%.

Embodiment 3

[0046] Under the protection of flowing nitrogen, 200ml of absolute ethanol was added into a 500ml reaction kettle, and then 1.4g of lithium metal was added. The process temperature was controlled at 40-50°C, and the reaction was stirred for 3 hours, and then concentrated to dryness under reduced pressure to obtain 10.3g of lithium ethoxide. The rate is 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com