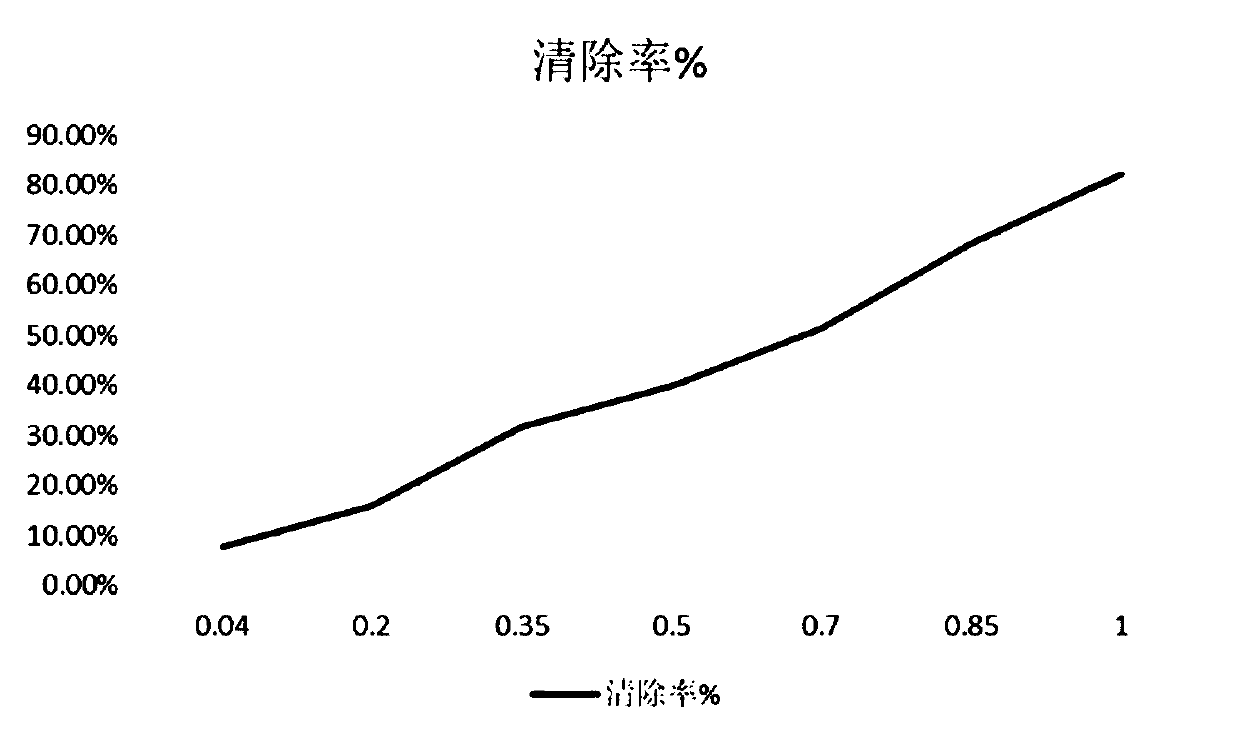

Preparation method and application of Euryops pectinatus fermented essential oil having strong antioxidant activity and high aroma

An antioxidant, chamomile technology, applied in the application, essential oil/spice, fat oil/fat production, etc., can solve the problem of low irritation, and achieve the effect of low irritation, low extraction temperature and strong anti-oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

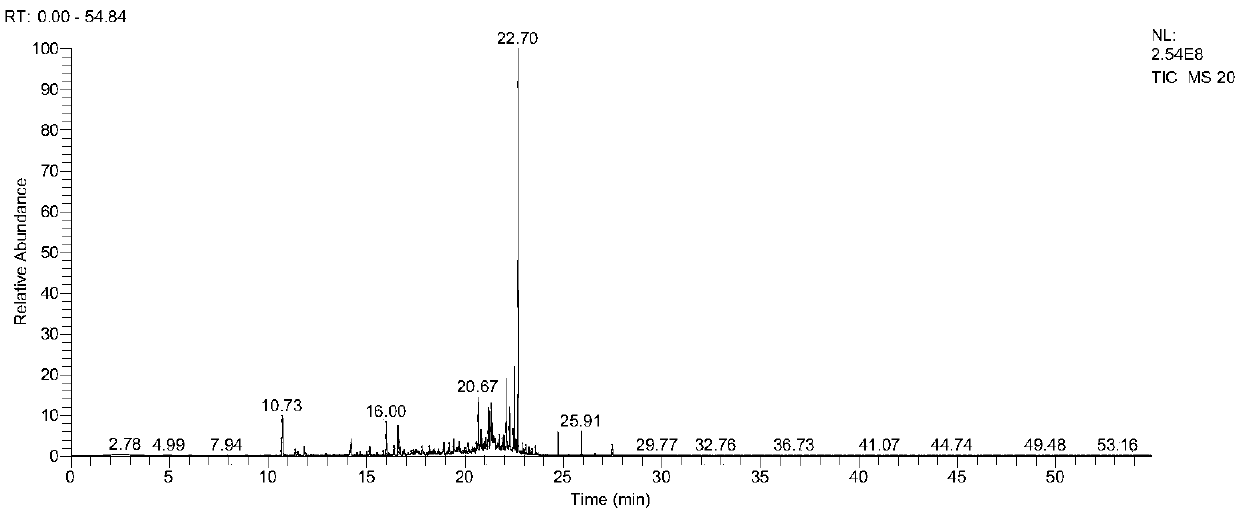

Embodiment 1

[0029] Preparation of a fermented absolute oil of Roman chamomile with strong antioxidant and high aroma:

[0030] (1) Low-temperature ultrafine pulverization: the Roman chamomile chrysanthemum air-dried flower slag after steam distillation extracts volatile oil is put into liquid nitrogen freezing ultrafine pulverizer and is pulverized into ultrafine powder, and the temperature of described liquid nitrogen freezing ultrafine pulverization is -2°C, the mesh number of ultrafine powder is 250 mesh;

[0031] (2) Synergistic hydrolysis fermentation: Roman chamomile superfine powder and water are mixed in a mass ratio of 1:8, acetic acid is added, and the acetic acid is analytically pure, pH 4.0 is adjusted, and oxidant H is added 2 o 2 , sodium ferrate (analytically pure, mass ratio is 1:0.5), accounts for 0.01% of the Roman chamomile slag superfine powder quality, then adds a certain amount of compound enzyme (acid protease, fructan sucrase, cellulase , pectinase, β-glucosidase...

Embodiment 2

[0035] Preparation of a Roman chamomile oil that improves aroma quality:

[0036] (1) Low-temperature ultrafine pulverization: put the air-dried flower residue of Roman chamomile into a liquid nitrogen freezing ultrafine pulverizer to pulverize (0° C.), the particle size is 280 mesh;

[0037] (2) Synergistic hydrolysis fermentation: first mix the superfine powder of Roman chamomile and water at a ratio of 1:12, add acetic acid (for analytical purity), adjust the pH value to 5.0, and add 0.015% of the mass of superfine powder of Roman chamomile flower dregs Oxidant H 2 o 2 and sodium ferrate (analytical pure, mass ratio is 1:0.8), then add the composite enzyme (acid protease, fructan sucrase, cellulase, pectinase, β- Glucosidase (mass ratio: 1:1:0.8:1:1) was mixed evenly, added to the fermenter, started the stirring motor, heated to 38°C, incubated and fermented for 8 hours, the compound enzymes were all food grade, and the enzyme activities were respectively 20,000, 80,000,...

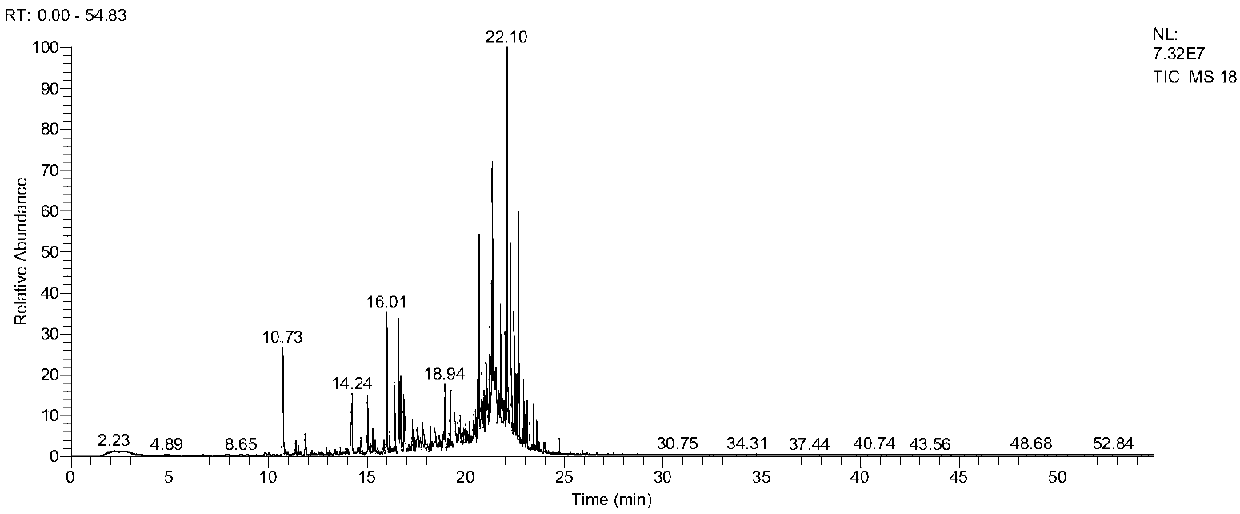

Embodiment 3

[0041] Preparation of a fermented absolute oil of Roman chamomile with strong antioxidant activity and high aroma:

[0042] (1) Low-temperature ultrafine pulverization: put the air-dried flower residue of Roman chamomile into a liquid nitrogen freezing ultrafine pulverizer to pulverize (2° C.), with a particle size of 300 mesh;

[0043] (2) Synergistic hydrolysis fermentation: first mix the superfine powder of Roman chamomile and water at a ratio of 1:15, add acetic acid (for analytical purity), adjust the pH value to 5.5, and add 0.02% of the quality of superfine powder of Roman chamomile flower dregs Oxidant H 2 o 2 and sodium ferrate (analytical pure, mass ratio is 1:1.2), then add the compound enzyme (acid protease, fructan sucrase, cellulase, pectinase, β- Glucosidase, the mass ratio is 1: 1.2: 1.2: 1.5: 1, all of which are food grade, and the enzyme activities are 100,000, 100,000, 200,000, 100,000, 10,000 u / g), mix well, and add to the fermentation tank , start the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com